Key Takeaways

Horsepower vs. Durability: High horsepower provides raw force, but blade metallurgy determines the Cost Per Ton.

The "Silent" Costs: Frequent downtime and blade sharpening account for up to 40% of total operational expenses (OPEX).

The Yuxi Standard: We use National Standard Steel and Special Alloy Tools combined with advanced heat treatment to ensure maximum wear resistance.

Investment Strategy: Stability comes from matching horsepower with blade durability, drastically reducing losses from downtime and parts replacement.

Introduction

In the industrial waste tire shredder machine, many buyers fall into the "Horsepower Trap." They assume a 200HP motor is twice as effective as a 100HP motor. However, raw power without high-performance metallurgy is like putting a Ferrari engine in a lawnmower. The real battle is fought at the cutting edge.

1.Breaking Down the Operational Expenses (OPEX)

When your shredder is offline for blade maintenance, you aren't just losing time; you are hemorrhaging profit.

Table 1: Visible Costs vs. Hidden Costs in Tire Shredding

| Cost Category | Visible (Initial) | Hidden (Ongoing) | Impact on Profit |

| Machinery | Purchase Price | Electricity & Lubrication | Moderate |

| Consumables | Blade Unit Price | Sharpening & Resurfacing | High |

| Labor | Operator Salary | Maintenance Downtime | Critical |

| Output | Capacity (t/h) | Unscheduled Breakdowns | High |

2. Metallurgy: The Science of Survival

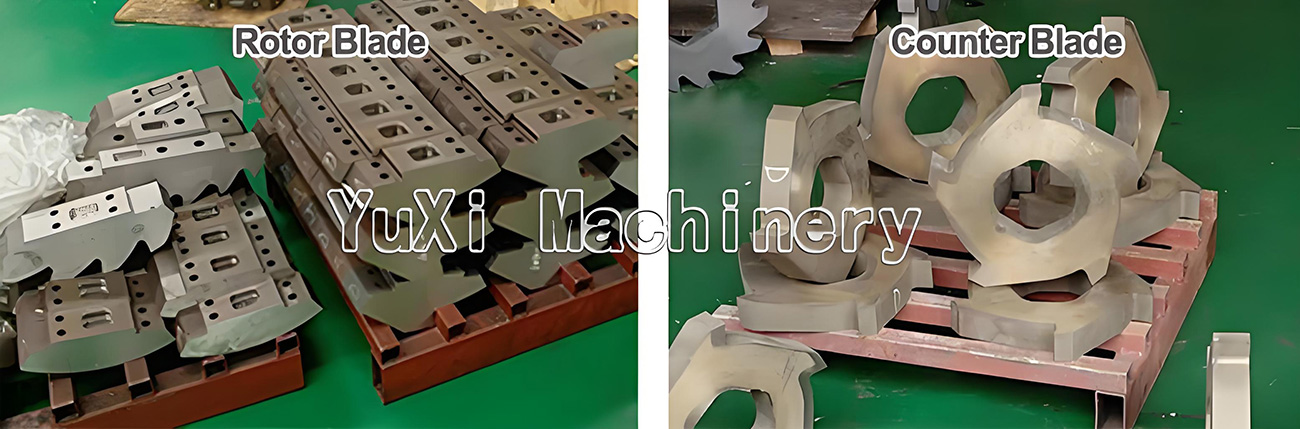

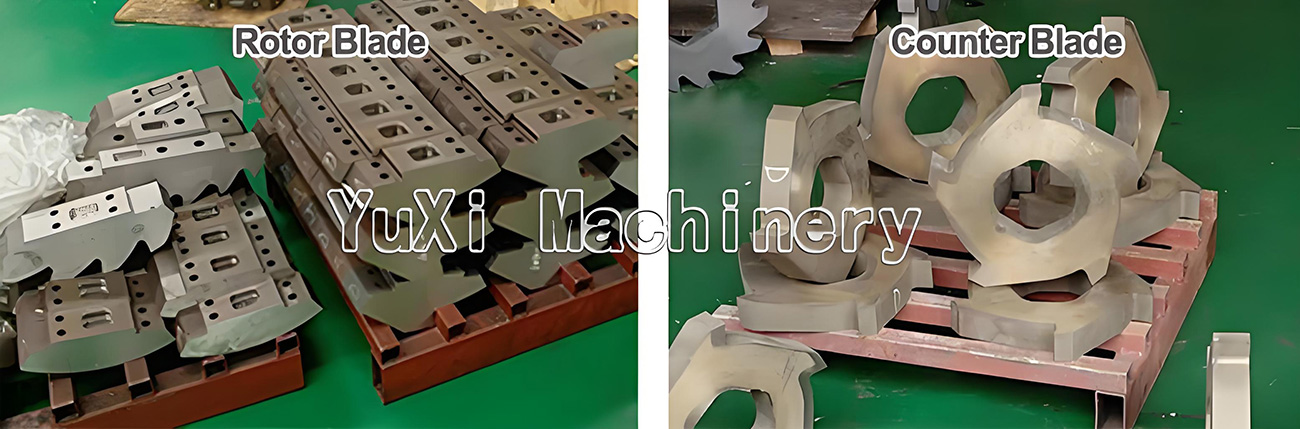

Tires contain high-tensile steel wires. Standard blades fail because they cannot balance Hardness and Toughness. To solve this, Yuxi utilizes high-quality National Standard Steel and Special Alloy Tools .

Table 2: Common Blade Materials and Their Performance

| Material Type | Hardness (HRC) | Toughness | Best For... | Expected Life (Tire Tons) |

| Standard Carbon Steel | 45-50 | Low | Light rubber, textile | < 150 Tons |

| 9CrSi / 6CrW2Si | 52-55 | Medium | Passenger car tires | 300 - 500 Tons |

| D2 (High Carbon/Chrome) | 58-60 | High | Steel-wire radial tires | 800 - 1,200 Tons |

| Yuxi Special Alloy | 60+ | Ultra-High | OTR and Mining tires | 1,500+ Tons |

3. How Poor Metallurgy Inflates Your Electricity Bill

Dull blades don't cut; they tear and grind. This increases the friction and the torque required from the motor.

Table 3: Energy Consumption Comparison (kW per Ton)

| Blade Condition | Efficiency Rating | Avg. kWh per Ton | Annual Power Cost (Est.) |

| New Yuxi Alloy Blade | 95% | 18 - 22 kWh | $54,000 |

| Worn Alloy Blade | 80% | 26 - 30 kWh | $72,000 |

| Dull Carbon Steel | 65% | 35+ kWh | $88,000+ |

4. The Downtime Math: A Profit Killer

Changing a set of blades on a dual-shaft shredder can take 8 to 16 hours.

Table 4: Yearly Downtime Analysis based on Metallurgy(Assumption: 8-hour work shift, 250 days/year)

| Blade Grade | Changes per Year | Total Labor Hours | Lost Production (Tons) |

|---|

| Standard Steel | 12 times | 144 Hours | 720 Tons |

| Mid-Range Alloy | 4 times | 48 Hours | 240 Tons |

| Yuxi Premium Alloy | 1.5 times | 18 Hours | 90 Tons |

5. Why Yuxi’s Special Heat Treatment Process Matters

Hardness is not just about the material; it's about the process. Yuxi blades undergo a Special Heat Treatment Process that ensures deep penetration of hardness while maintaining core flexibility.

Table 5: Heat Treatment Impact on Blade Durability

| Treatment Process | Resistance to Chipping | Edge Retention | Surface Hardness Consistency |

|---|

| Flame Hardening | Poor | Low | Uneven |

| Induction Hardening | Moderate | Medium | Surface only |

| Yuxi Vacuum Tempering | Excellent | High | Total Uniformity |

6. Summary: Total Cost of Ownership (TCO) Comparison

Only when Horsepower is perfectly matched with Blade Strength and Durability can the equipment guarantee long-term stable operation. This synergy is the key to reducing losses caused by downtime or frequent parts replacement.Then the fully automated tire recycling production line can operate stably.

Conclusion

Don't be blinded by horsepower alone. At Zhengzhou Yuxi Machinery, we believe that true performance comes from the perfect balance of raw power and metallurgical excellence. By using national standard materials and specialized heat treatments, we ensure your facility spends more time shredding and less time repairing, securing your long-term ROI.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment