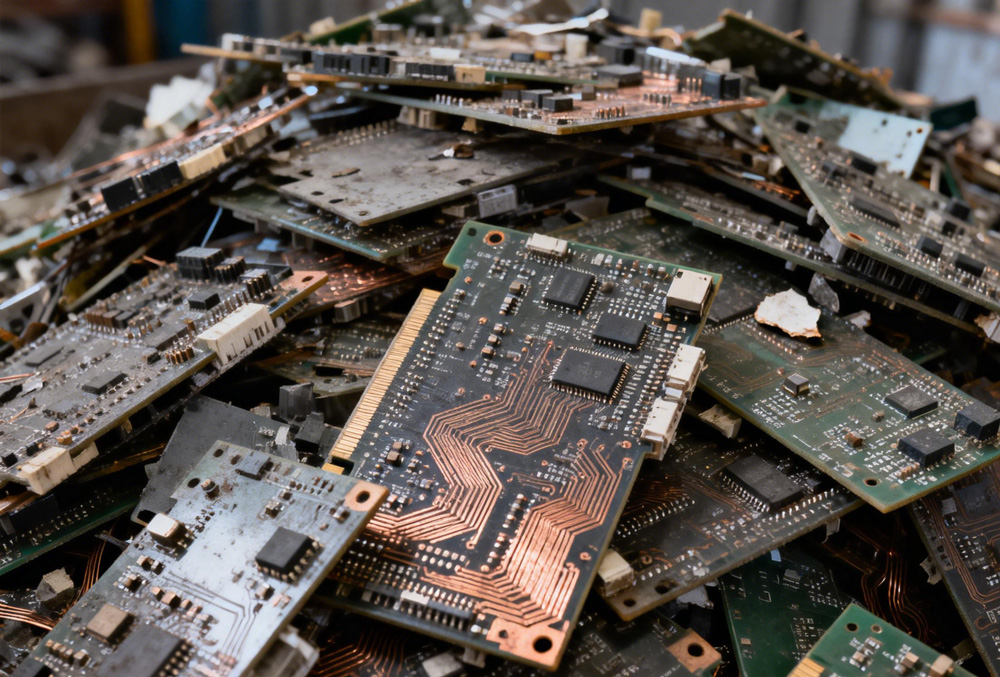

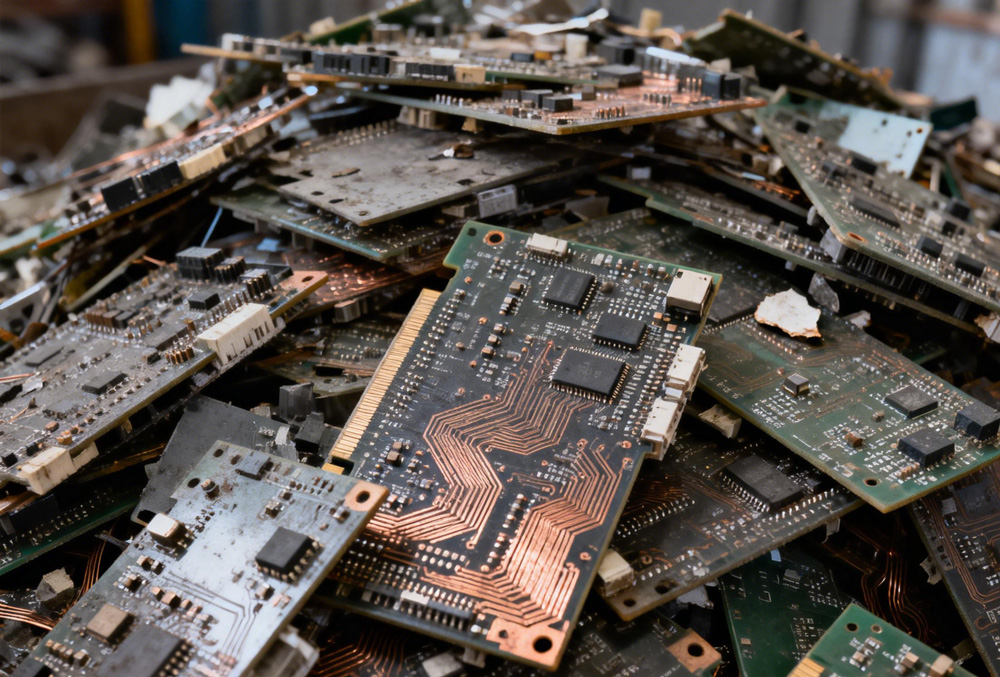

What is PCB in e-waste?

With the improvement of people's living standards, electronic devices, including mobile phones, tablets, computers, and televisions, all require PCB circuit boards. As products are updated and upgraded, the life cycle of electronic products is significantly shortened. This has not only spurred a huge consumer market but also brought about a series of profound industry changes and challenges. As the core carrier of electronic devices, how should we handle such a massive amount of e-waste?

How to dispose e-waste

Although often called "junk," discarded PCBs are actually a valuable "mine." Extracting precious metals like gold, silver, copper, and palladium from discarded circuit boards is dozens of times more efficient than mining metals from raw ore.

Resource Recycling: One ton of randomly generated mobile phone circuit boards contains far more gold than one ton of gold ore.

Circular Economy: This model of recycling resources from waste is becoming a new growth point for the environmental protection industry and the metal smelting industry.

In fact, it's not a matter of “shredding vs. recycling”. Rather, it's about the fact that shredding is a crucial first step in the recycling process in the entire chain, the e-waste industry.

You can think of recycling as the overall goal. It's about turning waste into raw materials, and shredding is one of the main steps in achieving that goal.

However, if you compare shredding (mechanical recycling) with other methods, such as manual dismantling or chemical leaching, each method has its own unique advantages and disadvantages.

Shredding: a mechanical method

Shredding is the standard method for industrial high-volume recycling. Machines break printed circuit boards into tiny fragments (usually less than 10 mm), thus “freeing” the metal from plastics and glass fibers.

Benefits:

Efficiency: thousands of boards per hour.

Automation: requires less labor than manual disassembly.

Data Security: Physically destroys any chips that may contain sensitive data.

Disadvantages:

Material Loss: Small amounts of precious metals are lost as “dust” during the grinding process.

Comparison: Shredding vs. Other Methods

| Feature | Shredding (Mechanical) | Manual Dismantling | Chemical Leaching (Hydrometallurgy) |

| Speed | Extremely High | Low | Medium |

| Material Purity | Moderate (mixed) | High | Very High (pure metals) |

| Best For | Bulk volume / Low-grade boards | High-value devices (Laptops/Phones) | Extracting Gold/Silver from dust |

| Environmental Risk | High (Dust/Noise) | Low (Safe if controlled) | High (Toxic liquid waste) |

How to remove data from electronics before recycling?

Deleting your personal data is the most important step before handing over your electronics to a recycling company. Simply deleting files or emptying the “recycle bin” is not enough, as data recovery software can easily retrieve this information.

The following is a professional workflow to ensure that your data cannot be recovered. 1:

1. Backup: Save photos, documents, and settings to an external hard drive or cloud service (Google Drive, iCloud, OneDrive).

2. Logout and De-association: *Accounts: Log out of your iCloud (Find My iPhone), Google or Microsoft account.

3. Wipe data

For smartphones and tablets (iPhone/Android)

Modern mobile devices are encrypted by default. Often, restoring factory settings is sufficient, as it destroys the encryption key and scrambles the remaining data.

iOS: Go to Settings > General > Transfer or reset iPhone > Wipe all content and settings. ".

Android: Go to Settings > System > Reset Options > Erase All Data (Restore Factory Settings).

Physical: Be sure to remove the SIM card and microSD card before recycling.

Use the built-in “Reset this PC” function. Select “Delete Everything” and then enable “Data Erase” in the settings. This will overwrite the data on the drive with zero.

If the device is damaged and won't power on, or if you have extremely sensitive data, physical destruction is the only 100% guaranteed means of keeping it safe.

4. Ensure absolute security

Drilling: Use a power drill to drill at least 3-4 holes in the drive platters.

Hammering: Use a hammer to shatter the glass/ceramic platters inside the hard disk with a few sharp blows.

Comparison of Erasure Levels

| Method | Best For | Security Level | Can Device be Reused? |

| Factory Reset | Modern Phones/SSDs | Moderate | Yes |

| Overwriting (Software) | Working Laptops/HDDs | High | Yes |

| Degaussing | Old HDDs/Tapes | High | No (bricks the drive) |

| Physical Shredding | Highly Sensitive/Broken | Absolute | No |

How do you mass crush these electronic devices?

To shred electronic equipment in large quantities and enter the industrial e-waste PCB recycling process, you can't rely on ordinary office shredders, you must use an industrial grade e-waste shredding system. This is a highly automated production line that usually contains the following core components and specialized equipment:

1. Core equipment: Industrial Shredders

Bulk shredding is usually multi-stage:

Double-Shaft Shredder: This is the most commonly used first stage. Two low-speed, high-torque shafts shred an entire computer, TV or washing machine into long strips.

Four-Shaft Shredder: Compared to the Twin-Shaft, the Four-Shaft Shredder has an additional set of screens to control the size of the discharge material, which allows for smaller, more uniform shredding of the equipment in a single pass, making it ideal for hard drives and circuit boards, where data destruction is critical.

Vertical Shredder: Using high-speed rotating hammer head impact, not only crushing, but also through the impact of the metal from the plastic shell, easy to follow the sorting.

2. Standardized Industrial Processes

In order to improve efficiency and protect the environment, large recycling centers usually follow the following pipeline:

Manual Pre-dismantling:

Manual dismantling of hazardous materials such as lithium batteries, ink cartridges, and mercury-containing lamps. If these items go directly into the shredder, they can cause explosions or serious environmental pollution.

Primary Shredding:

Crushes the entire machine into 5-10 cm pieces.

Magnetic Separation:

Use powerful magnetic pulley or hanging magnetic separator to suck out ferrous metals such as iron and steel from the crushed pieces.

Fine Granulation:

The remaining plastics and non-ferrous metals are further pulverized into particles smaller than 1 cm.

Eddy Current Separation:

Using the principle of electromagnetic induction, aluminum, copper and other non-ferrous metals are “popped” out of plastic and glass debris, realizing the automated separation of metals and non-metals.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment