Amid the dual trends of textile industry iteration and circular economy, textile waste shredders have become a core tool in the fields of garbage recycling, environmental treatment, and resource regeneration. This article directly addresses industry pain points, disassembling the entire process of equipment selection, operation and maintenance, and maximizing benefits from the dimensions of technical core, scenario adaptation, and cost control, while also clarifying the synergistic value of fabric shredders.

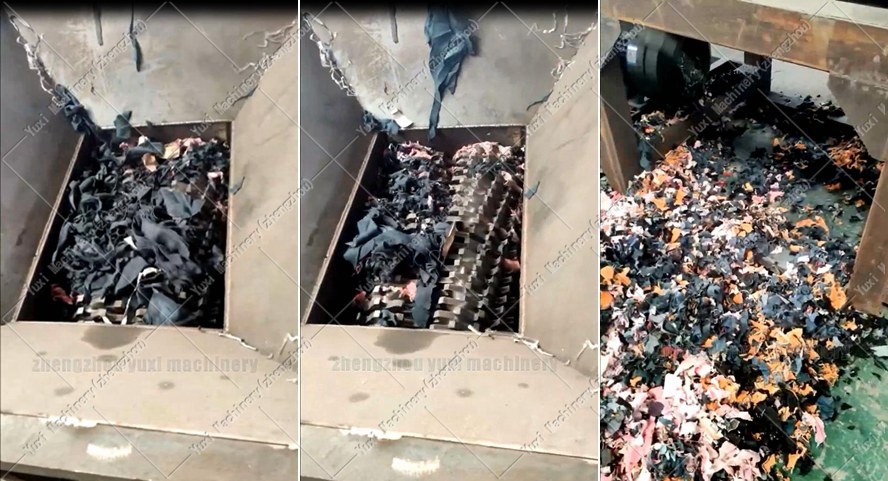

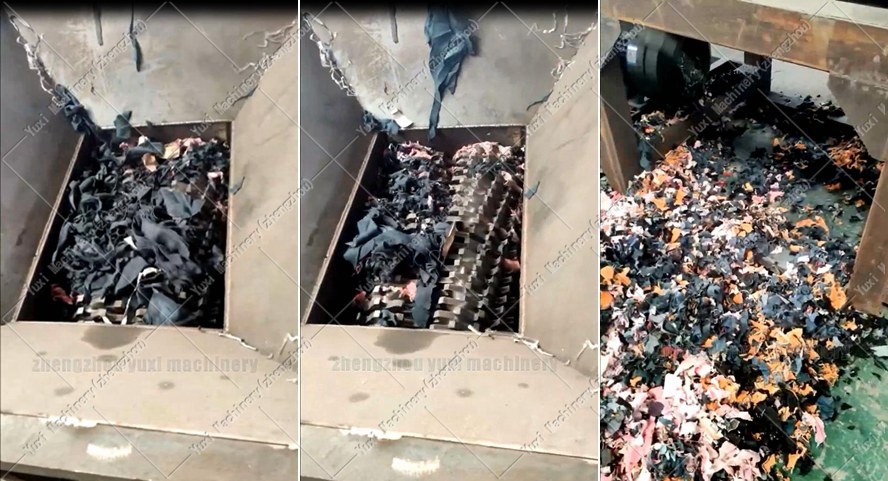

1. Technical Principle: "Shear-Tear" Dual-Shaft Crushing, Tackling Textile Solid Waste Challenges

The core of the textile waste shredder (dual-shaft shredding type) lies in its "shear + tear" composite crushing logic: The motor drives the reducer to output torque, which is transmitted to two relatively rotating moving knife shafts. The AISI 4340 alloy modular knife hooks on the shafts (through carburizing heat treatment, improving wear resistance by 30%) firmly hook and tear soft materials such as waste fabrics and old clothes; the bottom opposed roller fixed knives (scissor-edge design) then perform secondary shearing on the materials, ultimately outputting crushed materials of 1-4 inches (size can be customized).

Structurally, the ASTM A500 rectangular tube main frame ensures stability under high-intensity operations; the ASTM A514 quenched and tempered heat-treated crushing chamber extends the service life of the equipment; and SKF heavy-duty bearings withstand instantaneous impact forces—this combination enables the equipment to be both "capable of handling" and "durable" when processing materials such as waste cloth heads and chemical fiber side scraps.

2. Model Selection: Precise Matching According to Processing Capacity and Scenarios to Avoid Capacity Waste or Shortage

Different scales of textile solid waste treatment needs correspond to shredders with different parameters (taking the YXS series as an example), and choosing the right model directly determines operational efficiency:

| Model | Power (Horsepower) | Processing Capacity (Tons/Hour) | Hopper Size (Feet) | Equipment Weight (Short Tons) | Applicable Scenarios |

| YXS-600 | 40×2 | 2-3 | 2.69×2.95 | 2.75 | Small recycling points, laboratory sampling |

| YXS-1000 | 100×2 | 5-8 | 3.94×3.28 | 6.28 | Medium-sized recycling plant fabric crushing lines |

| YXS-1400 | 150×2 | 8-12 | 6.56×6.56 | 19.84 | Large-scale centralized textile solid waste treatment centers |

| YXS-2600 | 430×2 | 25-60 | 10.5×6.56 | 93.7 | Industrial-level textile waste recycling bases |

Selection Logic: For a daily processing capacity ≤ 50 tons, choose YXS-1000 or below; for a daily processing capacity exceeding 200 tons, YXS-2200/2600 is required—only precise matching can balance capacity and cost.

3. Scenarios and Materials: From Old Clothes to Composite Fabrics, One Equipment Handles Multiple Types of Solid Waste

The equipment can efficiently process waste cloth heads, waste cotton yarn, old clothes, cotton velvet, chemical fibers, linen, non-woven fabric scraps, and even expand to composite textiles such as old shoes, carpets, and quilts. The value logic of three core scenarios:

• Garbage Recycling Plants: Preprocess domestic waste mixed with textile waste to separate recyclable materials, reducing subsequent sorting costs;

• Environmental Treatment Companies: Provide front-end crushing for textile waste incineration and chemical recycling to improve material reaction efficiency and increase terminal revenue;

• Resource Recycling Enterprises: Process crushed materials into recycled cotton and non-woven fabric raw materials, achieving the value leap from "solid waste to raw materials".

4. Fabric Shredder: An "Efficiency Partner" for Pre-Processing

When dealing with bulky materials such as bundled old clothes and large-sized waste fabrics, a fabric shredder can be used for pre-processing: it uses a single/multi-shaft shredding principle to initially decompose large materials, which are then conveyed to the textile waste shredder for refined crushing. This "shredding + crushing" combination can avoid material blockage by large pieces, increasing the efficiency of the entire production line by more than 20%, and is especially suitable for projects with complex material forms.

5. Pain Point Solutions: Key Questions About Operation and Maintenance, Cost, and Material Processing

1. How to Maintain Worn Blades?

The modular knife hook design allows for individual replacement of knife sets when worn (without replacing the entire shaft), reducing costs by 40%; regular grinding of the blade edges with special grinding wheels can maintain shearing efficiency.

2. Can Old Clothes with Metal Attachments Be Processed?

A small amount of metal (zippers, buttons) can be processed for a short time, but long-term processing will accelerate blade wear. It is recommended to separate metals by magnetic separation or manually first, which not only protects the equipment but also improves crushing purity.

3. How to Choose Between Large and Small Models in Terms of Operating Costs?

Calculate the energy consumption per ton of material (for example, the YXS-1000 consumes approximately 111 kWh per ton of material processed), and then consider depreciation and maintenance costs—large models have lower unit costs and are suitable for large-scale projects with stable processing volumes; small models are flexible and suitable for scenarios with fluctuating processing volumes.

The textile waste shredder is a "breakthrough key" in the textile circular economy. Choosing the right equipment and using it correctly can not only solve the compliance problem of solid waste treatment but also seize profit opportunities in the renewable resource market. According to the technical disassembly and scenario adaptation logic in this article, you can precisely match your own needs and turn textile solid waste from a "burden" into a "gold mine".

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment