The world generates more than 50 million tons of e-waste every year, and electronic scrap shredders are the core equipment that turns "e-waste" into "urban mines"—1 ton of waste circuit boards can extract about 100 grams of gold and 2000 grams of silver, whose value far exceeds that of gold mines of the same weight. Untreated e-waste releases toxic substances such as lead and mercury, while shredders can efficiently recycle resources and avoid secondary pollution through mechanical sorting + physical separation technology.

1. Precise Disassembly and Volume Reduction

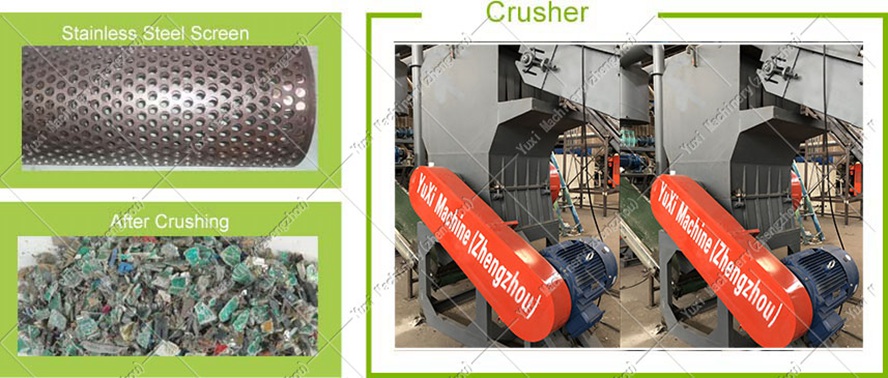

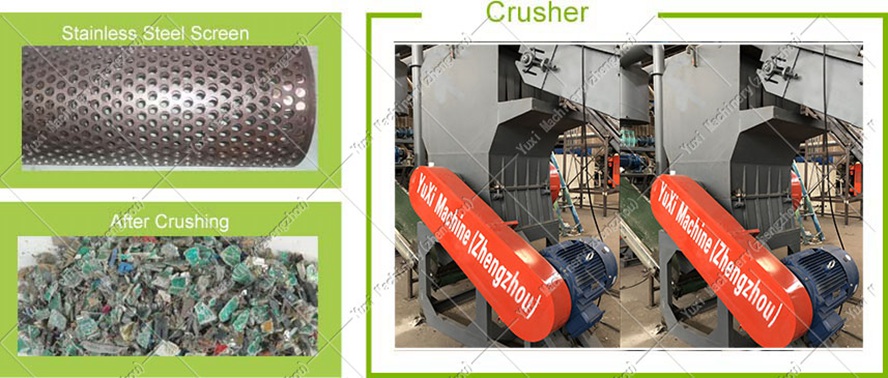

Through blade shearing, hammering or rolling, shredders decompose large pieces of e-waste into 2-5cm particles, reducing the volume to 1/10 of the original, which facilitates subsequent sorting and transportation.

Case: The Dutch company Eurometaux uses dual-shaft shredders to process waste servers, reducing warehouse occupancy from 100㎡ to 10㎡ and cutting transportation costs by 60%.

2. Efficient Separation of Metals and Non-Metals

Equipped with eddy current sorting and magnetic separation equipment, shredders can separate copper, aluminum, iron from plastics and resins, with a metal recovery rate of over 95%.

Case: Shenzhen GEM processes 100,000 tons of waste mobile phones with shredders every year, and the extracted metals are supplied to Huawei and BYD, realizing a closed loop of "from mobile phones to mobile phones".

3. Controllable Treatment of Toxic Substances

Equipped with dust collection and exhaust gas treatment systems, shredders can lock heavy metals such as lead and cadmium in particles to avoid environmental pollution.

Case: After German company Duesenfeld installed shredders with environmental protection systems for a waste treatment plant in New Delhi, India, the soil heavy metal content decreased by 40% and the air quality compliance rate rose to 92%.

4. Resource Utilization of Plastics and Glass

Crushed plastic particles can be used to make new electronic casings, and glass fibers can be used for building materials, realizing "full utilization of waste".

Case: American e-recycling company E-Cycle supplies plastic particles to Apple for the production of MacBook casings, reducing the use of 12,000 tons of virgin plastic every year.

5. Improvement of Waste Sorting Accuracy

Advanced shredders are equipped with intelligent sensing systems that can identify density differences of different materials, improving the sorting accuracy of metals, plastics and glass to over 98%.

Case: The shredder production line of Japan's Fuji Recycling can separate copper, aluminum and plastic from waste computers, with a processing capacity of 1500 kg per hour and a sorting error of less than 2%.

II. Types and Application Scenarios of E-Waste Shredders

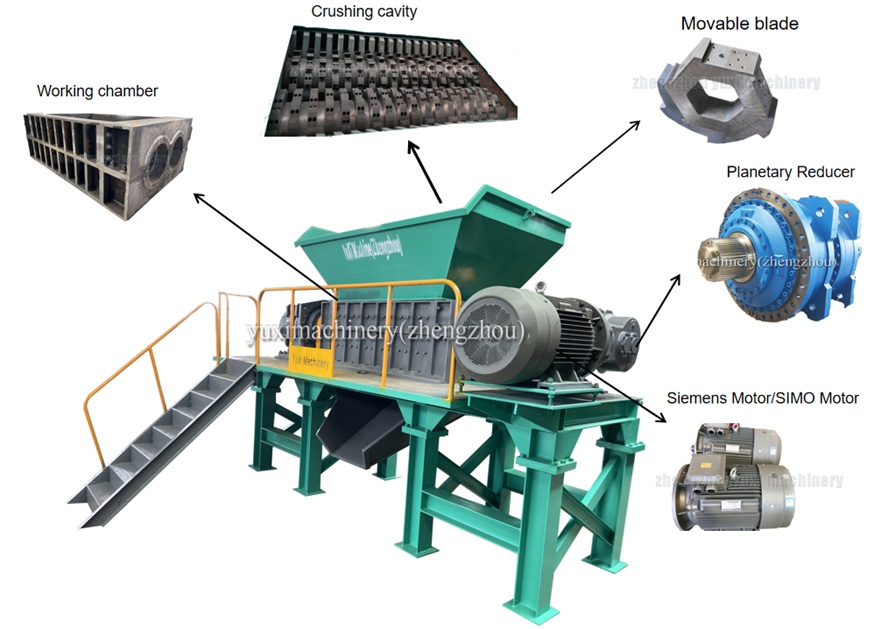

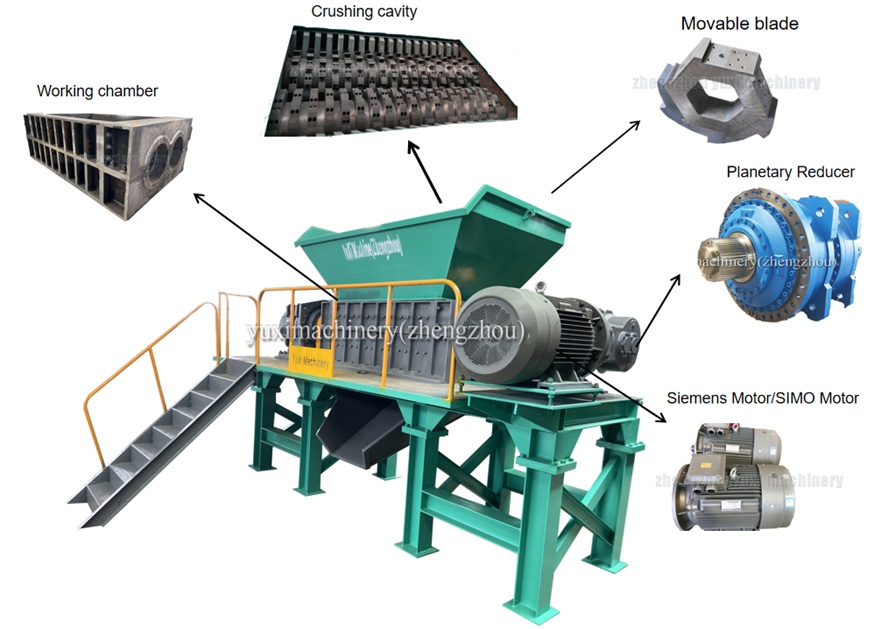

• Dual-shaft Shear Shredder: Relying on blade shearing + extrusion, it is suitable for large household appliances, servers and whole circuit boards, with a processing capacity of 500-2000 kg per hour and a motor power of 75-200 HP.

• Hammer Shredder: Relying on high-speed hammering and grinding, it is suitable for small waste such as mobile phones and power banks, with a processing capacity of 200-800 kg per hour and a motor power of 30-75 HP.

• Roller Shredder: Relying on roller extrusion and shearing, it is suitable for circuit boards and battery casings, with a processing capacity of 300-1000 kg per hour and a motor power of 40-100 HP.

• Low-temperature Freezing Shredder: By cooling plastic with liquid nitrogen to make it brittle, it is suitable for processing e-waste containing complex cables, with a sorting purity 12% higher than that of normal-temperature equipment and a motor power of 100-150 HP.

III. Energy Consumption and Operating Costs of E-Waste Shredders

1. Energy Consumption Level

• Dual-shaft shredder: About 50-80 kWh per ton of waste, suitable for large-scale recycling enterprises.

• Hammer shredder: About 30-50 kWh per ton of waste, suitable for small and medium-sized enterprises.

• Low-temperature freezing shredder: About 120-150 kWh per ton of waste, suitable for fine sorting of high-value waste.

2. Operating Costs

• Blade replacement: The blades of dual-shaft shredders need to be replaced after processing 500 tons of waste, with a cost of about 1200-1800 USD.

• Maintenance cost: The monthly maintenance cost is about 1%-2% of the total equipment price, mainly including lubricating oil and filter element replacement.

IV. Intelligent Upgrading and Digital Management of E-Waste Shredders

1. Intelligent Monitoring System

High-end shredders are equipped with temperature, vibration and current monitoring sensors, which can real-time warn of blade wear and bearing failures, reducing equipment failure rates by 30%.

Case: The intelligent shredders of Swedish company Eldan remotely monitor operating data through the Internet of Things system, reducing customers' equipment downtime from 12 hours per month to 3 hours.

2. Digital Sorting Management

Combined with AI image recognition technology, shredders can automatically identify rare metals (such as palladium and rhodium) in waste, increasing the recovery rate of high-value metals by an additional 5%-8%.

Case: The AI-assisted shredders of Canadian company Electra Recycling can accurately identify and sort palladium from waste circuit boards, creating an additional revenue of about 2 million USD every year.

V. Selection and Usage Guide for E-Waste Shredders

1. Pretreatment Requirements

• Remove flammable and explosive components such as batteries and capacitors before processing to avoid internal fire.

• Dry waste containing liquid (such as printer cartridges) first.

2. Installation and Maintenance

• Install in a well-ventilated room with a shock-absorbing base to avoid noise and vibration affecting the surrounding environment, and control the operating noise within 85 dBA.

• Check blade wear weekly and replace lubricating oil every 3 months to extend equipment life.

3. Environmental Protection Supporting Facilities

• Equip with bag filters and activated carbon adsorption devices to treat dust and harmful gases, with dust emission concentration below 10 mg/m³.

• Neutralize wastewater before discharge, with heavy metal concentration below 0.5 ppm.

4. Compliance Requirements

• Operators need professional training to master emergency shutdown and fault handling skills.

Frequently Asked Questions (FAQ)

1. Will the noise of e-waste shredders affect the surrounding environment?

Qualified equipment is equipped with sound insulation covers and shock absorption systems, and the operating noise can be controlled within 85 dBA, which meets industrial site standards; if installed near residential areas, sound insulation walls can be added to further reduce the impact.

2. Is there any safety risk in processing e-waste containing batteries?

As long as batteries are completely removed during pretreatment and the equipment is equipped with a fire monitoring system, risks can be avoided; some high-end equipment has a function of automatically detecting batteries and can stop for processing in time.

3. Is the energy consumption of e-waste shredders high?

For processing 1 ton of waste, the energy consumption of dual-shaft shredders is about 50-80 kWh, and that of hammer shredders is about 30-50 kWh, which is much lower than that of incineration or landfilling.

4. Which shredder is suitable for small recycling enterprises?

It is recommended to choose hammer shredders, which occupy a small area and are affordable, and can meet the processing needs of common waste such as mobile phones and small household appliances.

5. Which waste is suitable for low-temperature freezing shredders?

It is suitable for processing e-waste containing complex cables and flexible plastics, such as waste earphones and charging cables, which can make the separation of plastics and metals more thorough.

6. What are the benefits of digital management of intelligent shredders?

It can real-time monitor equipment status, early warn of failures and reduce downtime; combined with AI sorting technology, it can also improve the recovery rate of high-value metals and increase revenue.

Electronic scrap shredders are the key equipment connecting "e-waste" and "recycled resources". From warehouse volume reduction in the Netherlands to the "mobile phone closed loop" in Shenzhen, from pollution control in India to plastic replacement in the United States, and to intelligent monitoring in Sweden and AI sorting in Canada, such equipment is promoting e-waste treatment from "extensive landfilling" to "fine recycling + digital management".

When selecting and using shredders, choose the corresponding type according to the processing scale, do a good job in pretreatment, environmental protection supporting facilities and compliance management, and pay attention to energy consumption, operating costs and intelligent upgrading, so as to maximize the value of the equipment and contribute to the development of the circular economy.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment