Driven by both the circular economy in the textile industry and environmental policies, textile waste shredders have become a core piece of equipment for waste recycling plants and resource recovery enterprises to achieve "reduction and resource utilization" of textile solid waste. This article will provide a professional and practical technical guide for readers from four dimensions: equipment principles, process adaptation, sourcing decisions, and benefit calculation, while also explaining the key value of fabric shredders in the pre-processing stage.

1. Technical Core: The "Shear Shredding" Logic of Textile Waste Shredders

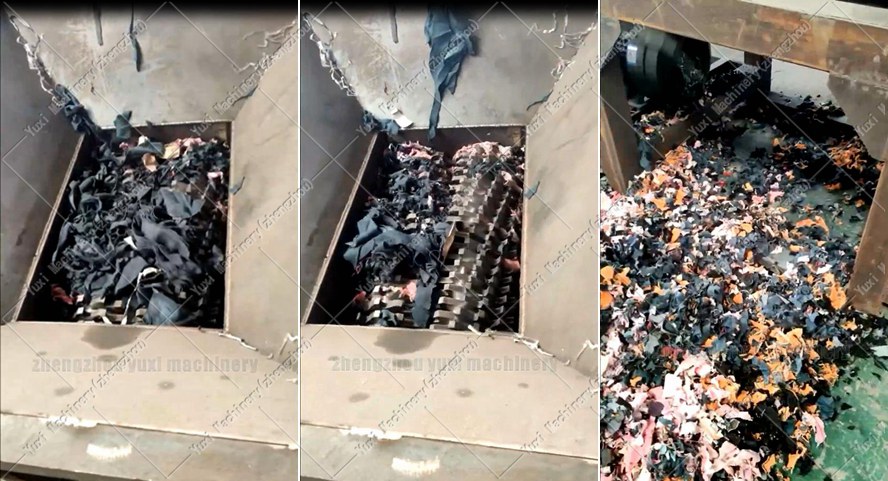

As a typical dual-shaft shear-type shredding equipment, its core working principle can be broken down into three stages: "power transmission - material shearing - finished product discharge":

• Power System: Uses European and American standard motors (such as Siemens and ABB series) to drive the reducer, and transmits torque through brand bearings like FAG/Timken to ensure power stability under heavy-load conditions.

• Shredding Mechanism: The "hook-type cutter teeth" of the moving cutter shaft and the "scissor-type blades" of the fixed cutter drum form a shearing pair, realizing the combined action of "tearing - shredding" for soft materials such as used clothes and fabric scraps. The shredding chamber is made of ASTM standard high-strength heat-treated steel plate, and its wear resistance life is more than 30% higher than that of ordinary steel.

• Structural Design: The main frame is welded with rectangular steel pipes, complying with ASME structural strength specifications, and can maintain equipment rigidity during 24-hour continuous operation.

2. Process Synergy: The Pre-Processing Value of Fabric Shredders

As a front-end supporting equipment for shredders, fabric shredders undertake the function of "primary tearing of large pieces of materials":

• Through multi-axis staggered cutter sets, large pieces of materials such as used fabrics and ready-made clothes are torn to an initial shredding size of 12-20 inches, solving the problems of "material jamming and low efficiency" when shredders directly handle large pieces of materials.

• The cutter shaft adopts a modular quick-change design, suitable for various textile scraps such as waste布头 (waste fabric ends), chemical fiber waste, and non-woven fabrics, laying a process foundation for the efficient shredding of subsequent shredders.

3. Sourcing Decisions: A Technical Table for Precise Matching of Production Capacity and Scenarios

Based on mainstream demands in the European and American markets, the following is a key parameter sourcing table for the YXS series textile waste shredders. Enterprises can accurately match according to daily processing capacity and site conditions:

| Model | Power (HP) | Processing Capacity (tons/hour) | Hopper Size (feet) | Equipment Weight (short tons) | Typical Application Scenarios |

| YXS-600 | 40×2 | 2-3 | 2.69×2.95 | 2.75 | Small recycling sites, laboratory-level processing |

| YXS-1000 | 100×2 | 5-8 | 3.94×3.28 | 6.28 | Regional environmental treatment centers |

| YXS-2000 | 240×2 | 16-22 | 7.55×6.56 | 38.58 | Centralized solid waste treatment in textile industrial parks |

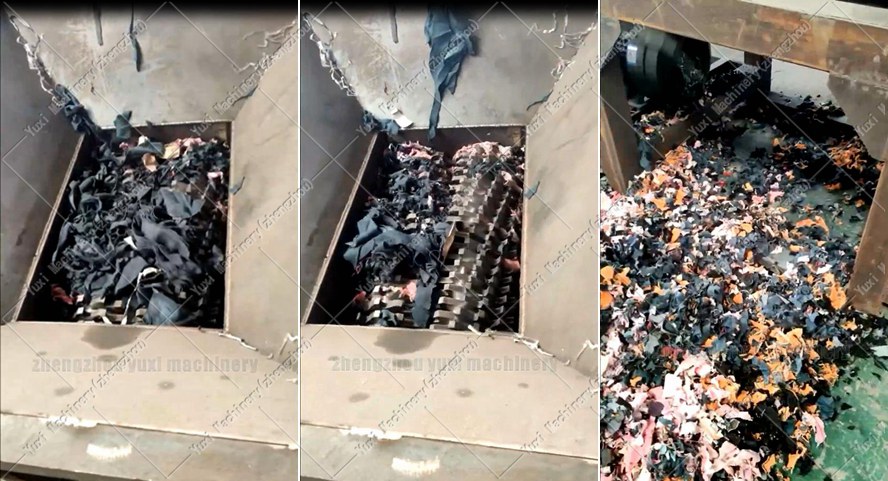

Note: The discharge particle size can be customized in the range of 1.18-3.94 inches to meet the particle size requirements of different downstream processes such as recycled textiles (e.g., geotextile raw materials) and incineration power generation.

4. Benefit Closed Loop: Quantitative Analysis from Environmental Compliance to Economic Benefits

The application of textile waste shredders can achieve dual optimization of "environmental costs" and "economic benefits":

• Environmental Compliance: Completely replaces extensive treatment methods such as landfilling and direct incineration, meeting the emission requirements of the U.S. Resource Conservation and Recovery Act (RCRA) and the EU Waste Framework Directive, and avoiding environmental fines of more than $1,000 per ton of textile waste.

• Economic Benefits: Taking the YXS-1600 model as an example, a processing capacity of 12-18 tons per hour can support a recycled textile production line, with an annual revenue of more than $1.5 million from converting used fabrics into recycled cotton raw materials; if equipped with an incineration power generation system, each ton of waste can generate approximately 500 kWh of electricity, and the annual power generation revenue can reach $800,000.

5. Q&A Direct Hit: 5 Practical Questions Most Concerned by Practitioners

1. Material Compatibility: What textile wastes can be processed?

It covers used clothes, leather materials, carpets, chemical fiber scraps, non-woven fabric waste, etc. It can also shred mixed textiles containing a small amount of metal zippers and buttons (large hard metals need to be removed in advance).

2. Process Connection: How to coordinate shredders and fabric shredders?

After the fabric shredder tears the material to 12-20 inches, it is directly conveyed to the textile waste shredder, which can increase the shredder's production capacity by 20%-30% and reduce the equipment material jamming failure rate.

3. Maintenance Cost: Service Life and Maintenance Cycle of Core Components?

The moving/fixed cutters are made of H13 heat-treated alloy steel, and their service life can reach 2000 hours when processing pure textile waste; the bearings need to be checked for lubrication every 500 hours, and the cutters need to be inspected for wear every 1500 hours and replaced as needed.

4. Customization Capability: What Parameters Can Be Adjusted According to Requirements?

Customization of discharge particle size (1.18-3.94 inches), hopper size, motor brand (European and American standards) is supported. For special working conditions, explosion-proof motors or corrosion-resistant materials can be upgraded.

5. Return on Investment: How Long Does It Take for SMEs to Recover Costs?

Taking the YXS-1000 model as an example, the equipment investment is about $250,000. If the profit per ton of processed recycled cotton raw material is $50 and the daily processing is 20 tons, the investment can be recovered in about 1.5 years.

The technical sourcing and process implementation of textile waste shredders are a core part of textile solid waste resource utilization. Through the technical analysis and scenario-based guidance in this article, enterprises can accurately match equipment and build an efficient pre-processing process chain, maximizing the economic value of textile waste while complying with environmental regulations.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment