For professionals in the metal recycling and processing industry, choosing the right scrap metal shredder means gaining a competitive edge in the "resource recycling + cost reduction and efficiency increase" race. This article breaks down the core technologies, differences between various models, and practical application logic of the equipment, starting from industry pain points, to provide you with directly implementable decision-making basis.

1. First, Address "Can It Be Used": Core Adaptability Parameters of Scrap Metal Shredders

When engaged in metal recycling, the first thing to clarify is whether the equipment can "accept" your raw materials and "produce" the required production capacity:

• Feed Size: Ranges from 4 to 118 inches, accommodating everything from small metal cans to large car frames, which can be fed directly without complex pretreatment.

• Production Capacity: 0.44 - 66 short tons per hour, suitable for everything from small and medium-sized recycling points to large processing centers.

• Applicable Materials: Lightweight metals such as paint buckets, diesel barrels, thin iron sheets, and car shells, as well as vehicle parts like used tires, engine casings, and old forklift pallets with a thickness of less than 0.39 inches, can all be efficiently shredded.

2. Then Understand "Why Choose It": Working Principle and Technical Barriers

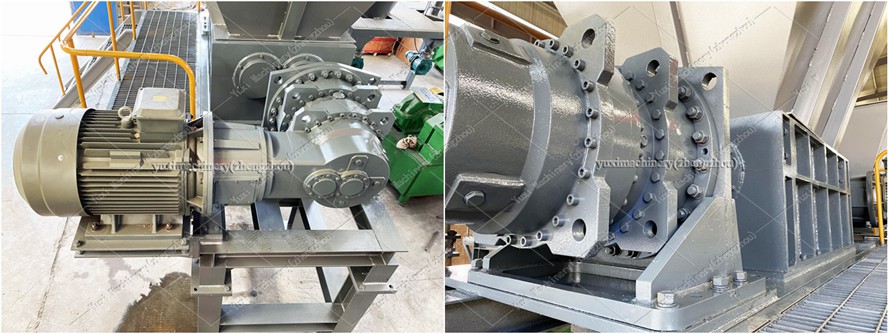

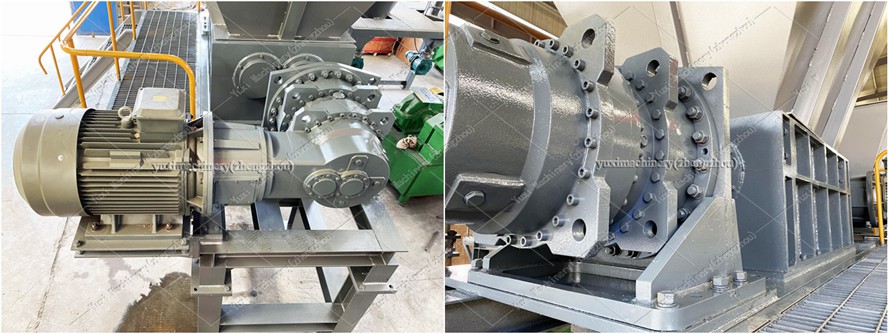

(1) Shredding Logic of Large Dual-Shaft Shredders

Taking the mainstream dual-shaft models in the industry as an example, they adopt an independent dual-shaft drive structure, achieving automatic feeding through the opposite extrusion of the two shafts, and will not get stuck even when processing high-toughness scrap metal. The core cutters are made of ASTM A1050 special alloy steel, and their wear resistance is increased by 30% after hardening treatment, and they support repair and reuse, greatly reducing consumable costs.

(2) Recessive Value of Professional Structural Design

• Split-Type Cabinet: The cutter shaft system can be quickly disassembled, reducing downtime by 50% during maintenance, especially suitable for factories with continuous production.

• Hexagonal Cutter Shaft + Spiral Cutters: The cutters are subjected to uniform force, increasing cutting efficiency by 20%; the spiral arrangement design makes the material shredding more uniform, making subsequent recycling and sorting easier.

• NEMA 4X Sealed Bearings: The waterproof and dustproof level reaches the top industrial standard. In the working condition of flying metal debris, the service life of the bearings is extended to 2.5 times that of ordinary models.

3. Small Scrap Metal Shredders: A "Cost-Effective Choice" for Small and Medium-Sized Recycling Scenarios

If you are a small and medium-sized recycler, the advantages of this type of model are more targeted:

• UL-Certified PLC Intelligent Control: One-button start and automatic reverse overload protection. Stable operation is possible without professional technicians, reducing labor costs by 40% directly.

• Low-Speed and High-Torque Transmission: The power combination of motor and reducer, even when shredding small hard metals (such as waste aluminum parts), consumes 25% less energy than traditional models.

• Customized Cutter Adaptation: Specialized cutters can be replaced according to materials (such as cans and waste copper sheets), increasing the recycling purity by 15% and directly increasing the selling price of recycled materials.

4. "Dual Benefits" of Environmental Protection and Economy

From the perspective of environmental compliance, dust and noise during equipment operation meet EPA emission and OSHA noise standards, so there is no need to worry about environmental inspection risks. From an economic perspective, the bulk density of scrap metal increases by 60% after being processed by the shredder, directly halving transportation costs. Moreover, the shredded metal has improved purity, reducing smelting energy consumption by 30% during recycling.

5. "Pit-Avoiding Q&A" Essential for Practitioners

1. Is Thicker Cutter Better?

No. The cutters made of ASTM A1050 material achieve "thin but hard" through surface hardening process. Excessively thick cutters will instead reduce cutting efficiency and increase energy consumption.

2. What to Do If the Production Capacity of Small Machines Is Insufficient?

You can choose a "small machine + assembly line" combination. By paralleling multiple machines or matching with conveying equipment, the production capacity can be increased to 15 short tons per hour, meeting medium-scale needs.

3. Are Imported Models Definitely Better Than Domestic Ones?

Not necessarily. Domestic leading brands have achieved localization of core technologies, and have more advantages in after-sales response (24-hour on-site service) and customized services, with a comprehensive cost 30% lower than imported models.

Whether you are a "veteran" in the metal recycling industry or an entrepreneur just entering the field, choosing the right scrap metal shredder is essentially "choosing an amplifier for production efficiency and profit". Precise selection based on your own raw material type, production capacity demand, and budget scale will allow you to run faster and more steadily in the track of metal circular economy.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment