In the field of metal recycling and processing, the scrap metal shredder is the core engine for realizing resource circulation. It solves the industry pain points of high material transportation costs and low recycling rates through efficient shredding of scrap metal, creating a closed-loop system for enterprises to reduce costs, increase efficiency, and achieve green development.

1. Core Parameters and Scene Adaptation: Choose the Right Equipment, Double the Efficiency

(1) Translation of Technical Parameters into Industry Language

• Feed Size: Covers the range of 4 - 120 inches, from small metal components to car frames, all can be fed directly without additional pretreatment.

• Production Capacity: The capacity spans 0.88 - 132,000 lbs/hour, which can be accurately matched from the scattered processing of small recycling points to the large-scale production lines of enterprises.

• Applicable Materials: All types of light, thin and medium-sized scrap metals such as metal barrels, color steel tiles, scrapped car shells/frames, aluminum plates, and decorative iron, realizing "one machine for multiple materials".

(2) Precise Matching of Industry Scenarios

• Automobile Dismantling Plants: For tough materials such as car shells and engine casings, through dual-shaft shredding technology, the materials are shredded to a uniform particle size, facilitating the separation and recycling of non-ferrous and ferrous metals, and the separation efficiency is increased by 40%.

• Small Recycling Points: The flexible capacity and portability of small scrap metal shredders are perfectly adapted to the processing of small batches and multi-category materials such as cans and small metal components, making "scattered recycling" also achieve efficient resource utilization.

2. Technical Principles and Structural Design: Understand the Principles to Know "What's Good" About the Equipment

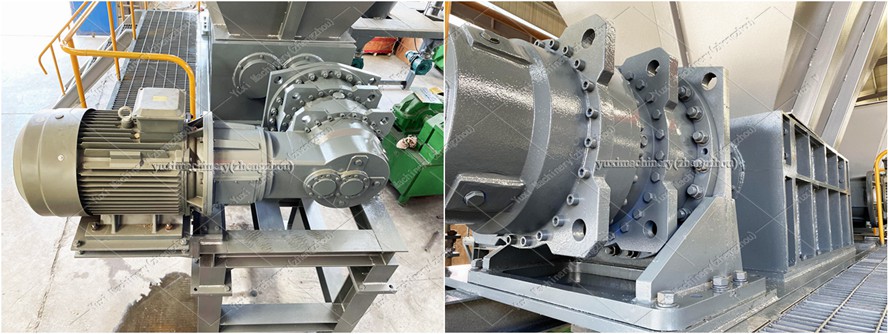

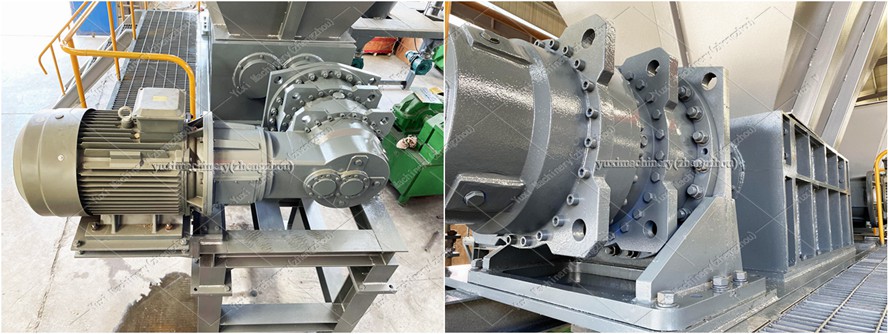

(1) Large-Scale Models: The "Aesthetic of Violent Shredding" Driven by Dual Shafts

Adopting a dual-shaft independent drive design, it performs composite shredding actions of extrusion + tearing on materials during operation to achieve automatic feeding. The special structure of its cutter shaft and cutters can operate stably under low-speed and high-torque working conditions, completely solving the problem of jamming of high-toughness materials (such as thick steel plates of cars), and the shredding efficiency is increased by 25% compared with traditional models.

(2) Small-Scale Models: "Technical Easter Eggs" of Refined Design

For small and medium-sized recycling scenarios, small machines reflect professionalism in details:

1. Intelligent Control: The PLC control system realizes fully automatic control of start, stop, reverse, and overload self-protection. One person can operate the entire production line, and labor costs are reduced by 30%.

2. Cutter Technology: Using AISI H13 special alloy steel cutters, processed through multiple special processes, wear resistance is increased by 50%, and repair and reuse are supported. The service life of cutters is extended to twice the industry average.

3. Protection Design: The bearing adopts IP67 grade sealing, with full waterproof and dustproof levels. In humid and dusty recycling environments, the bearing life is extended by 40%; the split box design shortens the cutter shaft disassembly and assembly time to within 30 minutes, greatly improving maintenance efficiency.

4. Cutting Optimization: The spiral arrangement of cutters + hexagonal cutter shaft/cutter hole design makes the cutters bear force evenly, cutting efficiency is increased by 20%, and at the same time avoids cutter chipping caused by local stress.

3. Application Value and Industry Significance: Buying Equipment is Buying a "Solution"

(1) Resource Utilization: Turn "Waste" into "Raw Material"

By shredding to reduce material volume and increase bulk density, transportation costs are reduced by more than 50%; the efficiency of subsequent sorting and smelting links is increased by 30%, and finally the scrap metal recycling rate exceeds 90%, helping enterprises seize the profit high ground in the "resource circulation" track.

(2) Compliance: The "Entry Ticket" in the Era of Environmental Protection

The low-noise and dust-control design of the equipment fully complies with European and American environmental emission standards (such as the US EPA exhaust emission standards and EU CE noise standards), ensuring that enterprises do not "step on mines" in environmental compliance, and the production process is green and pollution-free.

4. Q&A Zone: Directly Solve "Your Most Concerned Issues"

1. Q: Can the cutters of the small machine be changed according to the materials?

A: Yes. For materials of different materials/shapes such as cans, thin iron sheets, and thick steel plates, corresponding types of cutters can be selected to achieve "precise shredding" and avoid efficiency waste caused by "overkill" or "underutilization".

2. Q: Can the high capacity of large machines be sustained and stable?

A: Absolutely. Take the 2600 model as an example, its capacity can reach 55 - 132 tons/hour, and the equipment adopts heavy-duty design, which can run continuously for 16 hours without pressure, and the stability of large-scale production is fully guaranteed.

3. Q: Is equipment maintenance difficult? What should be focused on?

A: The maintenance logic is very clear - focus on cutters and bearings. Regularly check the wear of cutters (replace/repair when wear exceeds 3mm); pay attention to the sealing and lubrication of bearings, and conduct a comprehensive maintenance every 500 hours. The annual maintenance cost is only 5% of the equipment purchase cost.

A scrap metal shredder is not just a simple "shredding tool", but a "profit engine" and "compliance shield" for metal recycling and processing enterprises. Whether you are a large dismantling plant with large-scale layout or a small recycling point with refined operation, you can find a suitable technical solution here, making "scrap metal recycling" a truly efficient, compliant and profitable business.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment