The textile industry generates tens of millions of tons of used clothing and leftover materials every year, and inefficient crushing is the core pain point hindering waste resource utilization—problems such as fiber entanglement in equipment, uneven particle size of crushed materials, and difficulty in impurity separation have trapped countless recycling projects in the dilemma of "high investment and low return". This article dismantles the core technologies of equipment and the details of production line implementation, accurately addressing the three core needs of "equipment selection, efficiency improvement, and cost control", while also analyzing the pretreatment value of textile shredders.

1. Textile Waste Shredders: Customized Crushing Solutions for Fiber Materials

The strong toughness and easy entanglement characteristics of textile waste (cotton, chemical fiber, blended fabric, etc.) require equipment to break away from traditional crushing logic. The following disassembles the core technologies from process design to performance parameters:

1.1 Crushing Chamber and Cutter System: Solving "Fiber Entanglement + Efficient Crushing"

• Cutter Innovation: Adopt a combination of "multi-tooth staggered moving cutter + self-cleaning fixed cutter". The moving cutter is made of 42CrMo high-carbon chromium-molybdenum steel, undergoing vacuum quenching + cryogenic treatment (hardness HRC60-64), and the "sawtooth microstructure" of the cutting edge enhances the "shearing-tearing" effect on fibers; the fixed cutter is equipped with an "anti-entanglement chip removal groove", forming "bite crushing" with the moving cutter to completely solve the problem of chemical fiber yarn entangling the cutter shaft.

Example: When processing polyester filament waste, the cutter tooth pitch is controlled at 2-4mm, which can accurately cut the fibers into pieces ≤5mm, meeting the particle size requirements for recycled spinning.

• Crushing Chamber Design: The inner wall of the chamber has a "streamlined diversion arc surface" + "side negative pressure air suction channel" (wind speed ≥12m/s), making the waste form a "swirling crushing field", which not only prevents fiber accumulation but also assists in discharging materials by wind force. The volume of the chamber is precisely matched with the processing capacity (e.g., for processing 800kg of waste per hour, the effective volume of the chamber is ≥1.5m³) to ensure stable crushing rhythm.

1.2 Drive and Control System: Adapting to the Load Characteristics of Fiber Materials

• Power Configuration: A combination of "high-power motor + hard-tooth-face reducer", selected according to the characteristics of the waste—

◦ For pure cotton thin leftover materials: A 15HP (about 11kW) motor can meet the processing capacity of 500kg per hour;

◦ For thick webbing/chemical fiber blocks: Upgrade to a 30HP (about 22kW) motor, combined with a hydraulic coupling to achieve "soft start" and avoid starting load impact on the power grid and equipment.

• Intelligent Speed Regulation: The PLC + frequency conversion system monitors the feed rate and motor current in real-time, automatically adjusting the moving cutter speed (1000-3000r/min)—when the feed is piled up (current exceeds 110% of the rated value), the speed increases to more than 2500r/min to enhance crushing force; when the feed decreases, it drops to 1500r/min to reduce energy consumption and cutter wear.

1.3 Screen and Discharge System: Defining Product Particle Size & Separation Precision

• Screen Technology: Provide specifications such as 1/16", 1/8", 3/16" (corresponding to Φ1.6/3.2/4.8mm), using Mn13 laser-drilled wear-resistant screens (aperture tolerance ≤0.05mm) to ensure the uniformity of crushed material particle size; for high-precision requirements, a "double-layer classification screen" can be selected to achieve "coarse crushing + fine crushing" in one go.

• Discharge Separation: High-end models integrate an "air-specific gravity separation device", which separates fiber crushed materials from metal/plastic impurities by wind force (air volume ≥3000m³/h), improving the purity of recycled materials and reducing subsequent separation costs.

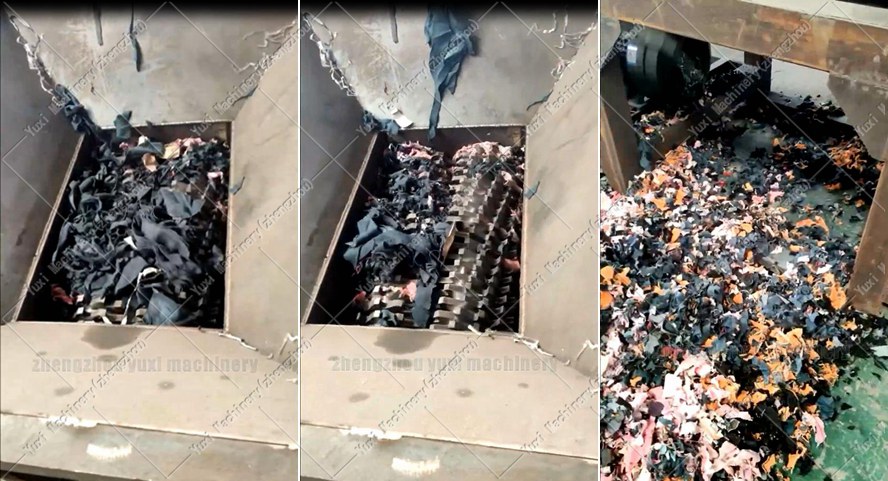

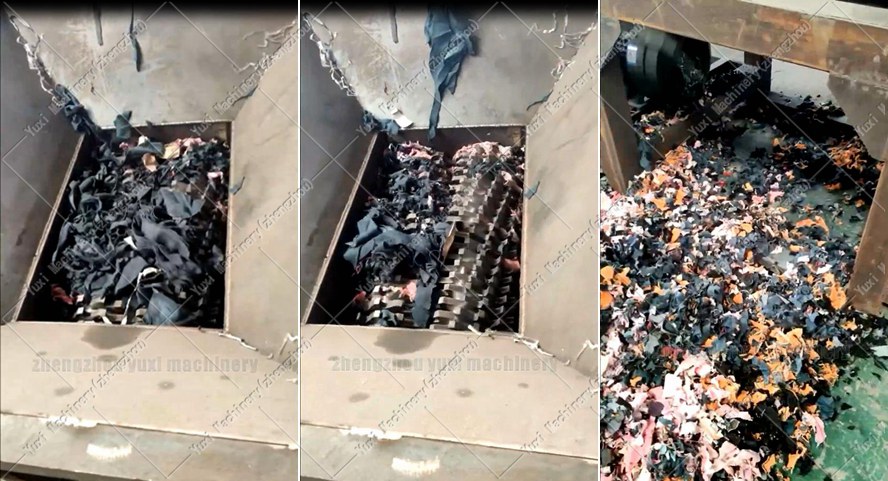

2. Textile Shredders: The Key to "Breaking Entanglement and Disaggregating" in the Pretreatment Stage

Textile shredders are the core pretreatment equipment before crushing, responsible for crushing large pieces of waste (used clothing, whole rolls of leftover cloth, etc.) to a size suitable for shredders. The design focuses on "anti-entanglement and high crushing efficiency":

• Structural Features: Double-shaft counter-roller cutter disc group, with "rectangular hook cutter teeth" on the cutter discs arranged in a spiral and staggered manner (tooth density ≥12 teeth/10cm), performing "extrusion-tearing" on cloth/webbing, and the size of the crushed material is 15-30cm (adjustable by the tooth pitch of the cutters). The cutter disc is made of Mn18 wear-resistant high manganese steel, and its wear resistance life is 3 times that of ordinary steel when dealing with denim/thick webbing.

• Production Line Collaboration: The discharge port of the shredder is connected to the feed hopper of the shredder through a "sealed belt conveyor channel", and the conveying speed is precisely matched with the processing capacity of the shredder (e.g., if the shredder outputs 1200kg of crushed material per hour, the shredder needs to correspond to a processing capacity of ≥1200kg/h) to prevent waste from scattering/entangling and ensure continuous operation of the production line.

3. "Pit-Avoidance Guide" for Equipment Selection & Production Line Implementation

3.1 Performance Testing Standards (Core Basis for Procurement/Acceptance)

• Wear Resistance Test: After the cutter continuously processes chemical fiber hard materials for 1500 hours, the edge wear is ≤0.8mm; the thickness loss of the wear-resistant liner (high chromium cast iron) in the crushing chamber is ≤1.2mm.

• Particle Size Stability: Under the rated feed rate, run continuously for 10 hours, and the particle size deviation of the crushed material is ≤8% (e.g., for a model with a nominal 1/8" screen, the proportion of crushed material >5/32" in the discharge is <3%).

• Safety Protection: When the feed is blocked, the motor current exceeds 125% of the rated value, and the system stops within 1.5 seconds; after the emergency stop button is triggered, the moving parts stop within 0.3 seconds, and it has a fault self-diagnosis function.

3.2 Industry Pain Point Solutions

• Treatment of Waste Containing Impurities: Add an "8000GS permanent magnet iron remover" in front of the feed port of the shredder to adsorb metal impurities; the shredder has a built-in "elastic anti-collision cutter seat" to avoid cutter cracking when dealing with hard impurities such as plastic blocks.

• Small-Batch Recycling Projects: Choose modular equipment of "shredder + shredder", supporting single-machine/combined operation to reduce initial investment; at the same time, require manufacturers to provide "sample testing service" and confirm equipment adaptability based on actual crushing effects of waste samples.

4. FAQ (Most Concerned Questions of Recycling Practitioners)

Q1: What is the difference between a textile shredder and an ordinary garbage shredder?

The fiber toughness of textile waste is much higher than that of ordinary garbage. Therefore, the textile shredder has higher cutter tooth meshing precision (tooth side clearance ≤0.5mm) and larger cutter shaft torque reserve (twice that of the same specification garbage shredder), and the feed port is equipped with a "30r/min fiber拨料辊" to prevent entanglement; ordinary garbage shredders are designed for hard materials and are prone to shaft entanglement and low efficiency when processing textile waste.

Q2: How to quickly determine whether the equipment is suitable for my waste?

Provide three core pieces of information to the manufacturer: ① Waste type (pure cotton/chemical fiber/blended); ② Hourly processing capacity; ③ End-use of the finished product (recycled spinning/filling material, etc.). Priority is given to manufacturers that support "free sample testing" and confirm the selection based on the actual crushing effect.

The technological iteration of textile waste shredders is essentially a deep understanding of the "crushing law of fiber materials". Whether purchasing equipment or planning a recycling production line, grasping the three details of "cutter, chamber, and collaborative process" can truly realize the "efficient volume reduction + high-value recycling" of waste. If you are promoting a recycling project, you can start from the "performance standards + pain point solutions" in this article to accurately screen suitable equipment and avoid detours.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment