When a ten-year-old solid wood sofa, a mattress with deformed springs, or an obsolete refrigerator is discarded, it not only occupies a large area next to community trash cans but also becomes a "bottleneck" in the urban waste management system. According to the United Nations Environment Programme, the global annual output of bulky waste has exceeded 120 million tons. The traditional model of "manual disassembly + landfilling and incineration" is not only inefficient but also causes a huge waste of recyclable resources such as wood, metal, and plastic.

Many people may ask: Is a bulky waste shredder worth buying? The answer lies in its technical logic, industry data, and practical value—this equipment is redefining the disposal path of bulky waste from a technical perspective, turning "massive waste" into "recyclable resources".

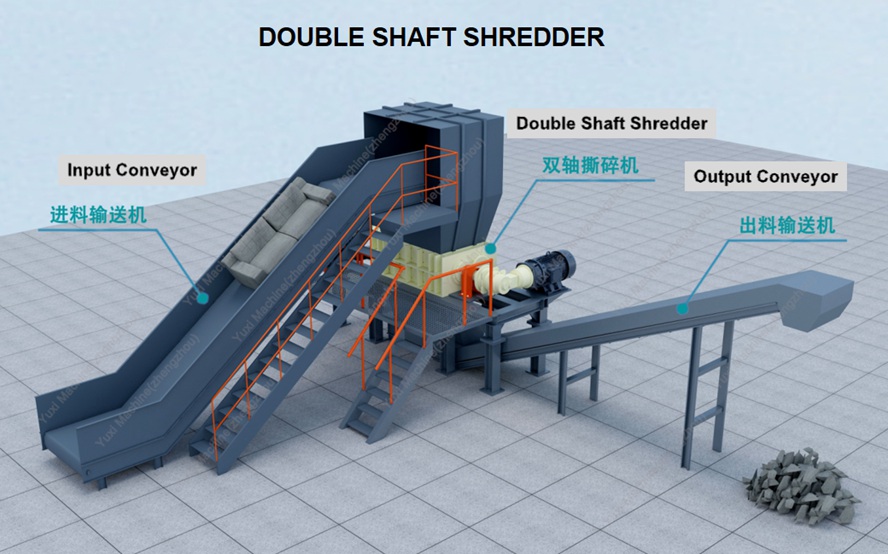

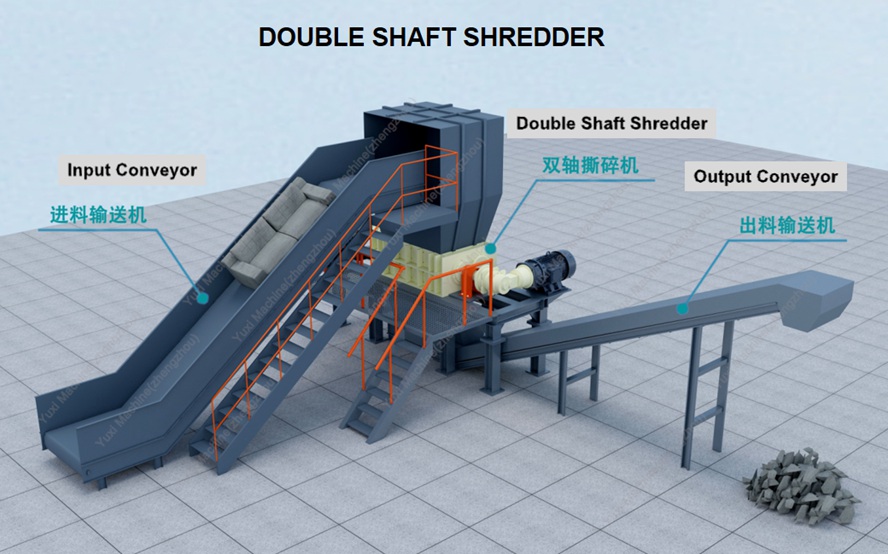

I. Technical Dissection of Bulky Waste Shredders: From Structure to Workflow

A bulky waste shredder is not a single "shredding machine" but an integrated system consisting of 5 core modules, each of which determines the efficiency and effectiveness of the equipment:

1. Feeding and Pretreatment Module

• Feed Hopper: Adopts a hydraulically driven reversible design, capable of accommodating bulky waste with a height of 5-6.5 feet. The width of the feed inlet is usually between 4-6.5 feet, suitable for large items such as sofas and wardrobes;

• Pretreatment Device: Equipped with a rotary cutting knife, which can first cut off the protruding parts of the waste (such as table legs of furniture and armrests of sofas) to avoid material jamming.

2. Core Shredding Module

• Primary Shredding: Uses "shear-type blades" composed of 2-4 groups of hydraulically driven blades, which can cut bulky waste into 20-40 inch blocks;

• Secondary Shredding: Adopts "extrusion-type rollers" with raised tooth patterns on the surface, which can extrude block materials into 4-8 inch small pieces;

• Tertiary Shredding: Uses "hammer-type hammers" to further crush small pieces into 2-4 inch particles, meeting the needs of subsequent sorting.

3. Sorting Module

• Magnetic Separation System: Uses a high-intensity magnetic roller, which can separate ferromagnetic metals (such as mattress springs and furniture hardware) from materials with a separation rate of over 98%;

• Air Separation System: Separates light materials such as wood and plastic from heavy materials through air flow generated by a fan, with a separation accuracy of 90%;

• Manual Auxiliary Sorting: A sorting table is set at the end of the conveyor belt, where workers can manually separate residual materials such as glass and rubber.

4. Discharging and Conveying Module

• Conveyor Belt: The width is usually 2.5-4 feet, and the speed is adjustable (1.6-4.9 feet/second), which can convey the shredded materials to the designated container;

• Discharge Port: Equipped with a rotatable discharge chute, which can send different types of materials into corresponding recycling bins respectively.

5. Control System

• PLC Control System: Can realize automatic start-stop, fault alarm, and parameter adjustment of the equipment, and some high-end equipment supports remote monitoring;

• Safety Protection Device: Built-in overload protection, material jamming detection, and emergency stop button to avoid equipment damage and safety accidents.

II. Core Value of Bulky Waste Shredders: Advantages Behind the Data

1. Volume Reduction Efficiency: From "Space Occupation" to "Cost Saving"

• Solid Wood Furniture: Original volume is about 90 cubic feet per piece, and the volume after shredding is about 6 cubic feet per piece, with a volume reduction rate of 93%;

• Mattress: Original volume is about 63 cubic feet per piece, and the volume after shredding is about 4.2 cubic feet per piece, with a volume reduction rate of 93%;

• Home Appliance Shell: Original volume is about 42 cubic feet per piece, and the volume after shredding is about 2.8 cubic feet per piece, with a volume reduction rate of 93%;

• Calculated based on processing 1,000 pieces of bulky waste per month, 10 trucks of 22,000 pounds are needed for transportation before shredding, while only 1 truck is needed after shredding, reducing transportation costs by more than 90%.

2. Resource Recycling: From "Waste" to "Recycled Raw Materials"

• Wood: The shredded wood chips can be made into biomass fuel (calorific value of about 7200-8100 BTU/pound) or recycled boards (such as density boards and particleboards);

• Metal: The separated metal can be sent to smelters. Each ton of iron can save 3300 pounds of iron ore, and each ton of aluminum can save 8800 pounds of bauxite;

• Plastic: The shredded plastic particles can be made into recycled plastic (such as trash cans and pipes), and each ton of recycled plastic can save 6600 pounds of crude oil;

• According to industry data, for every ton of bulky waste processed, about 660 pounds of wood, 220 pounds of metal, and 110 pounds of plastic can be recycled, creating a direct economic value of about 50-80 US dollars.

3. Environmental Protection and Emission Reduction: From "Pollution" to "Low Carbon"

• Landfill Comparison: When the shredded materials are landfilled, the leachate production is reduced by 95%, and the methane emission is reduced by 90%;

• Incineration Comparison: When the shredded materials are incinerated, the emission of harmful gases is reduced by 80%, and the incineration efficiency is increased by 30%;

• Calculated based on processing 10,000 tons of bulky waste per year, the carbon dioxide emission can be reduced by about 4.4 million pounds, which is equivalent to planting 100,000 trees.

III. Application Scenarios and Selection Details of Bulky Waste Shredders

1. Classification of Application Scenarios

• Urban Waste Treatment Centers: Suitable for equipped with fixed shredders with a processing capacity of 10-20 tons per hour, which need to be matched with sorting and recycling systems;

• Communities/Properties: Suitable for equipped with mobile shredders with a processing capacity of 2-5 tons per hour, which can provide on-site processing on demand;

• Furniture Factories/Home Appliance Factories: Suitable for equipped with special shredders with a processing capacity of 5-10 tons per hour to handle scrap products during the production process;

• Construction Waste Treatment Plants: Suitable for equipped with heavy-duty shredders with a processing capacity of 15-25 tons per hour to handle construction waste containing bulky waste.

2. 6 Key Details for Selection

• Processing Capacity: Choose according to the daily processing volume. For example, if the daily processing volume is 50 tons, select equipment with a processing capacity of 10 tons per hour (calculated based on 5 hours of work per day);

• Blade Life: The service life of alloy tool steel blades is about 500-800 hours, and the service life of high manganese steel blades is about 1000-1500 hours;

• Energy Consumption Parameters: The power of equipment with a processing capacity of 10 tons per hour is about 74-100 HP, and the energy consumption per ton of waste processed is about 6-8 kWh;

• Noise Control: The operating noise of the equipment should be ≤85 dBA, and it is necessary to equip a sound insulation cover or set it in a closed workshop;

• Dust Control: Equipped with a bag filter, the dust emission concentration should be ≤0.02 grains/ft³, meeting relevant environmental protection requirements;

• After-sales Service: Choose manufacturers that provide 24-hour fault response, blade replacement, and equipment maintenance services.

IV. Daily Maintenance and Fault Handling of Bulky Waste Shredders

1. Daily Maintenance Points

• Daily Maintenance:

1. Check the appearance of the equipment and clean up residual materials in the feed hopper and conveyor belt;

2. Check the oil level and pressure of the hydraulic system to ensure they are within the normal range;

3. Check the wear of blades and rollers and record the wear degree;

4. Lubricate the bearings and chains of the equipment with lithium-based grease.

• Weekly Maintenance:

1. Check the tension of the conveyor belt, and adjust the tension device if it is loose;

2. Check the magnetism of the magnetic separation roller, and contact the manufacturer for magnetization if the magnetism weakens;

3. Clean the filter bags of the bag filter to ensure smooth ventilation.

• Monthly Maintenance:

1. Replace the hydraulic oil and filter element, and the hydraulic oil should be replaced every 2000 hours;

2. Check the wiring of the PLC control system to ensure there is no looseness;

3. Fully fasten the equipment to prevent bolt loosening.

• Quarterly Maintenance:

1. Check the wear of the blades, and grind or replace them if the edge wear exceeds 0.08 inches;

2. Check the tooth pattern of the rollers, and replace the rollers if they are severely worn;

3. Conduct no-load operation test on the equipment to ensure all modules work normally.

2. Common Fault Handling

• Material Jamming Fault:

1. Press the emergency stop button and turn off the equipment power;

2. Open the inspection door of the feed hopper and clean up the jammed materials;

3. Check if the blades are deformed, and replace them if they are;

4. Restart the equipment and test whether the feeding is normal.

• Excessively Fast Blade Wear:

1. Check if the fed materials contain metal or hard materials, which need to be separated in advance;

2. Adjust the blade gap to ensure it is within the normal range (0.04-0.12 inches);

3. Replace with more wear-resistant blade materials, such as tungsten carbide blades.

• Insufficient Pressure of Hydraulic System:

1. Check the oil level of the hydraulic oil, and add hydraulic oil if it is insufficient;

2. Check the working status of the hydraulic pump, and replace it if it is damaged;

3. Check if the hydraulic pipeline is leaking, and replace the sealing ring if it is.

• Conveyor Belt Deviation:

1. Turn off the equipment power and adjust the tension device of the conveyor belt;

2. Adjust the guide roller of the conveyor belt to return the conveyor belt to the center position;

3. Check the wear of the conveyor belt, and replace it if it is severely worn.

Frequently Asked Questions (FAQ)

1. Can bulky waste shredders handle all types of bulky waste?

Most can, including solid wood furniture, mattresses, sofas, home appliance shells, cabinets, etc. However, flammable and explosive items (such as refrigerant tanks of old refrigerators), sharp glass pieces, and batteries need to be removed in advance to avoid damaging the equipment. For furniture containing a lot of glass (such as glass dining tables), the glass parts need to be separated in advance.

2. Is the initial investment of bulky waste shredders high?

• Mobile Shredders: The price is about 50,000-100,000 US dollars per unit;

• Fixed Shredders: The price is about 150,000-300,000 US dollars per unit;

• Calculated based on processing 1,000 tons of waste per month, the equipment investment can be recovered within 1-2 years.

3. Do bulky waste shredders require special personnel to operate?

Yes, operators need to receive training from the manufacturer to master the equipment's operation process, safety precautions, and simple fault handling. Usually, 1-2 operators are needed for one equipment.

4. How to sell the shredded materials?

• Wood: Can be sold to biomass fuel factories or board factories at a price of about 50-80 US dollars per ton;

• Metal: Can be sold to scrap recycling stations at a price of about 200-300 US dollars per ton (iron) and 1500-2000 US dollars per ton (aluminum);

• Plastic: Can be sold to recycled plastic factories at a price of about 100-150 US dollars per ton.

Returning to the question at the beginning—Is a bulky waste shredder worth buying? The answer is: For institutions that need to process a large amount of bulky waste and pursue resource recycling and cost control, it is not only "worth buying" but also a core equipment to achieve "waste reduction, resource utilization, and harmlessness". From a technical perspective, it is a complex system integrating shredding, sorting, and control; from a value perspective, it can compress the volume of bulky waste to 1/15, recover more than 90% of resources, and reduce 95% of pollution emissions; from an economic perspective, it can recover the investment within 1-2 years and continuously create recycling benefits. For urban environmental protection and resource circulation, bulky waste shredders are not an "optional equipment" but a "must-have solution".

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment