What’s the most frustrating issue for scrap recycling practitioners? —— Waste metal takes up space, transportation costs are high, crushed materials are difficult to compress, and equipment breaks down frequently... This article thoroughly explains the core technologies, selection know-how, and entire line adaptation logic of hydraulic metal balers, and also provides practical solutions for the coordination points of small metal crushers, helping you choose the right equipment and use the right methods to turn the "troublesome item" of scrap recycling into a "profit point".

I. Hydraulic Metal Baler: The Core Logic to Solve Scrap Recycling Pain Points

Why can’t mature recycling plants do without hydraulic metal balers? Because they can compress the volume of waste metal, waste paper, and other materials to 1/3-1/5 of the original volume, directly reducing transportation and storage costs; and the durability and pressure stability of the equipment determine whether the production efficiency can remain stable. The gap between high-quality balers and inferior equipment lies in every process detail.

1. Core Components: Choose the Right Material, Double the Equipment Lifespan

• Main Pressure Cylinder & Sealing System:

The cylinder barrel uses SAE 1045 precision honed seamless steel pipe (with mirror-smooth inner wall, roughness Ra ≤ 0.8μm), and the piston rod uses AISI 4140 chrome-plated round steel (chrome plating thickness ≥ 0.04mm). Matched with Parker imported seals, even when working under high pressure of 25-31.5MPa for a long time, it can achieve "no oil leakage for ten years".

• Hopper & Pressure Head:

The side plates and face plates are made of ASTM A572 Grade 50 alloy steel plates (20mm thick plates for 100-ton models), and the working surface of the pressure head is surfacing welded with more than 5mm thick tungsten carbide wear-resistant layer —— When dealing with steel edges and aluminum chip burrs, the wear speed is directly halved.

• Material Pushing Mechanism:

The material pushing cylinder and material pushing head adopt a spherical hinge + self-lubricating copper sleeve design, which can offset the lateral force during material pushing, and the service life of the oil seal is extended by at least 30%; the face plate of the material pushing head is also surfacing welded with a wear-resistant layer, and it will not deform after long-term material pushing.

2. Hydraulic System: Stable Pressure and Low Energy Consumption Are Truly Efficient

• Power & Pressure Control Logic:

Equipped with Rexroth A4VSO constant power variable piston pump + explosion-proof motor (30HP motor for 100-ton models), realizing "fast downward pressing when no load, and automatic slow pressing when encountering hard materials", which saves 30% energy compared with the old quantitative pump system, and can save tens of thousands of yuan in electricity bills a year.

• Valve Group & Monitoring:

Using YUKEN cartridge valve group, the response speed is ≤ 0.2 seconds, and the pressure head can switch between return and pressure maintaining with one button; the pressure relay + displacement sensor monitor the pressure and stroke in real time, ensuring that the compression density of each block of material is uniform, and it is more convenient for subsequent smelting and melting.

• Cooling & Filtration:

The air cooler keeps the oil temperature below 122°F, and the return oil filter has an accuracy of ≤ 10μm —— If impurities cannot enter, the wear of the valve group and pump body will be reduced, and the equipment failure rate will be directly reduced by half.

3. Small Metal Crusher: Only "Matched" with Baler to Be Efficient

The crusher is a "rough processing assistant" before baling, but mismatching is a waste of money:

• Parameter Matching:

The rotor speed is selected as 800-1200r/min, the hammer head is made of ASTM A128 Type B water-toughened manganese steel (hardness HB300-350), and the screen aperture is 50mm smaller than the hopper inlet of the baler (for example, if the baler inlet is 400×600mm, the screen is selected as ≤ 350mm) to ensure that the crushed materials can enter the baler smoothly.

• Entire Line Flow Design:

The production capacity of the crusher and the baler must be 1:1 (for example, if the crusher crushes 2 tons per hour, the baler must compress 2 tons per hour); the belt conveyor + vibrating feeder is used for feeding in the middle, and the materials should not be piled up at the feed inlet, otherwise the baler will either be idling or overloaded, and the service life of the equipment will drop rapidly.

II. Selection & Application: Choose Equipment According to Your "Scrap Situation"

Different scraps and different sites require very different baler selection methods. This part breaks down "how to choose" into specific scenarios, and you can follow them to find the right one, no longer worrying about choosing the wrong equipment.

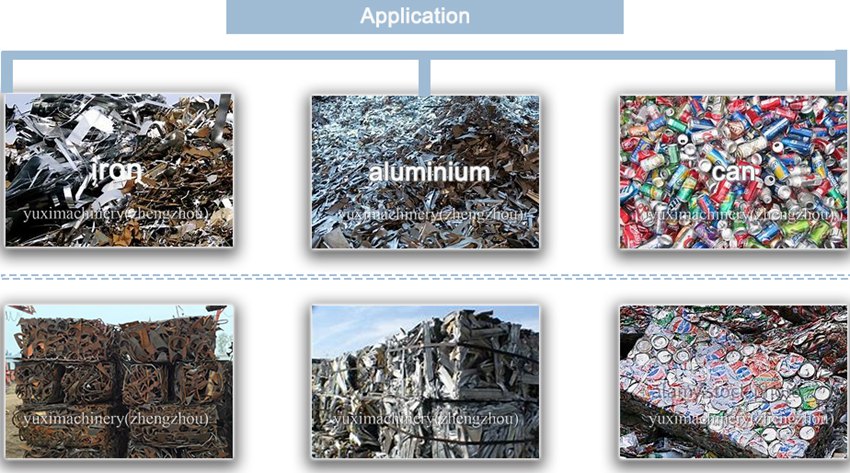

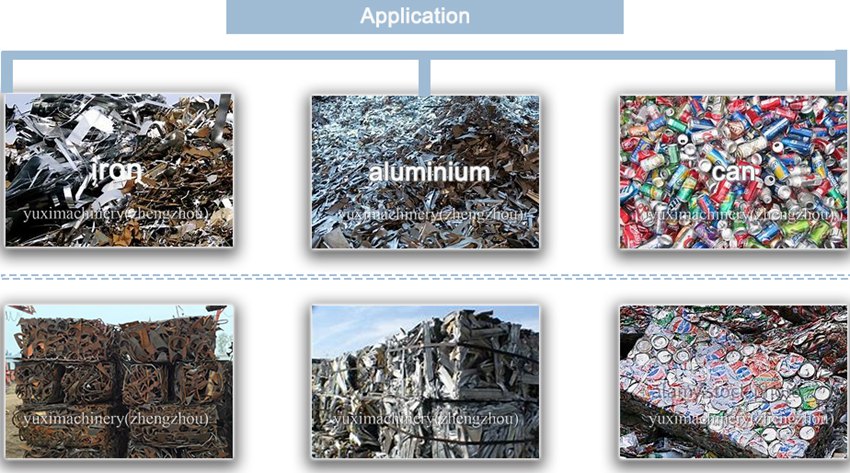

1. Select Models According to Scrap Types

• Waste Steel/Thick-Walled Scrap (such as scrapped car shells):

Choose a vertical baler with a main pressure cylinder pressure ≥ 2000kN, a hopper length ≥ 2500mm, and an additional secondary compression mechanism —— Is thick-walled material difficult to compress? The secondary compression can increase the density to more than 3.5t/m³, so that the truck bed can be filled more when transporting.

• Waste Aluminum/Lightweight Materials (such as cans, aluminum foil):

Priority is given to horizontal balers with "pre-pressing chamber + main pressing chamber" —— First pre-press the fluffy aluminum chips into blocks (pre-pressure ≥ 500kN), and then push them to the main pressing chamber for final pressing, no longer worrying about lightweight materials "not being pressed tightly and rebounding easily".

• Mixed Collection of Multiple Materials (such as waste metal + waste paper):

Choose a multi-functional baler with a partition plate in the hopper, and the hydraulic system can adjust the pressure gear —— High pressure for hard metal and low pressure for soft waste paper, one equipment can handle multiple materials without buying additional machines to occupy space.

2. Acceptance & Commissioning: These Details Determine Whether the Equipment "Works Well"

• Structural Acceptance:

The hopper welds should be inspected by UT ultrasonic flaw detection, and they are qualified only if there are no cracks; when the pressure head runs on the guide rail, the gap is ≤ 0.5mm, and there should be no jamming or noise, otherwise it will need to be repaired soon after use.

• Performance Test:

When no load, the fast forward speed of the pressure head is ≥ 150mm/s, and the return speed is ≥ 200mm/s; when fully loaded with rated materials, the pressure drop is ≤ 1MPa after 5 minutes of pressure maintaining, and the dimensional error of the formed block is ≤ ±20mm —— If this number is not reached, it means that the pressure is unstable, and it will get worse as it is used later.

• Safety Configuration:

The hopper inlet should be equipped with light curtain protection, emergency stop button, and protective net, and the safety switch should be interlocked with the main motor —— There are many people and complex operations in the scrap recycling site, and one less safety configuration is a potential risk.

3. Finding an OEM Manufacturer: Focus on These Three Points to Avoid Being Cheated

• The factory must have CNC machining centers, hydraulic test benches, and welding robots —— Without these equipment, the precision of the baler produced will definitely be poor.

• It should be able to provide equipment process data packages (such as component drawings, hydraulic schematics) —— These materials are needed for later maintenance and equipment modification.

• Full-process quality inspection is required for small orders (raw materials, process, and finished products are all inspected) —— Some manufacturers fool around when receiving small orders, and finally the equipment has a lot of problems when received.

III. Quick Answers to Common Questions: Solve All "Difficult and Complicated Diseases" of Scrap Recycling

Q1: Is the higher the compression density, the more money saved in transportation?

Not necessarily. High-value metals (copper, aluminum) can be compressed as much as possible (such as aluminum chips compressed to more than 2.0t/m³), but low-value lightweight materials (waste iron sheets) should not be forced to pursue density —— Over-compression will prolong the baling cycle and reduce efficiency instead. You need to calculate the balance value of "compression density × baling speed" to find the most profitable point.

Q2: Can balers be used in sites without power supply?

Yes. Equipped with a Cummins 4BT series diesel engine-driven hydraulic pump station, the fuel tank is designed for 4-hour endurance, plus a manual emergency operation valve —— Discharging can be done without electricity, and the diesel engine can also drive the equipment to work, and scrap can be recycled even in remote sites.

Q3: Where is the maintenance cost mainly spent?

• Hydraulic seals: The oil seals of the main pressure cylinder and material pushing cylinder need to be inspected and replaced every 5000 hours;

• Wear-resistant layer: The surfacing layer of the pressure head and material pushing head needs to be welded once a year when processing hard scraps;

• Hydraulic oil: Use ISO VG46 anti-wear oil and replace it every 2000 hours —— Don’t be greedy for cheap and use inferior oil, the cost of repairing the pump and valve group once is enough to buy dozens of barrels of good oil.

The hydraulic metal baler is a "profit lever" for scrap recycling —— Choosing the right equipment and using the right method can turn the "processing cost" of scrap into "capital for making money". If you are looking for equipment or an entire line solution, give priority to manufacturers with hydraulic research and development and structural customization capabilities (such as Zhengzhou Yuxi Machinery), which can make solutions according to your scrap type and site conditions, adapt to waste steel, waste aluminum, etc., and can also handle no-electricity sites and small-batch customization, and meet international standards such as ANSI and CE, which is convenient for expanding overseas business in the later stage. It is recommended to first ask the manufacturer for a "equipment working condition simulation report" and then test the prototype to see with your own eyes whether the equipment works well in your own site.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment