Meta Description: What do textile waste shredders do? This article breaks down their volume reduction/sorting functions, selection methods, maintenance tips, plus real factory/recycling plant cases to help you cut costs and boost income from waste—with FAQs included.

1. First, Understand: What Is a Textile Waste Shredder, and Why Is It Industry-Standard?

The global textile industry generates 92 million tons of waste annually (UN 2024 data), over 60% of which consists of defective garments, production scraps, and used home textiles. These bulky materials take up space, incur disposal fees for landfilling, and pollute when incinerated—long a major industry headache.

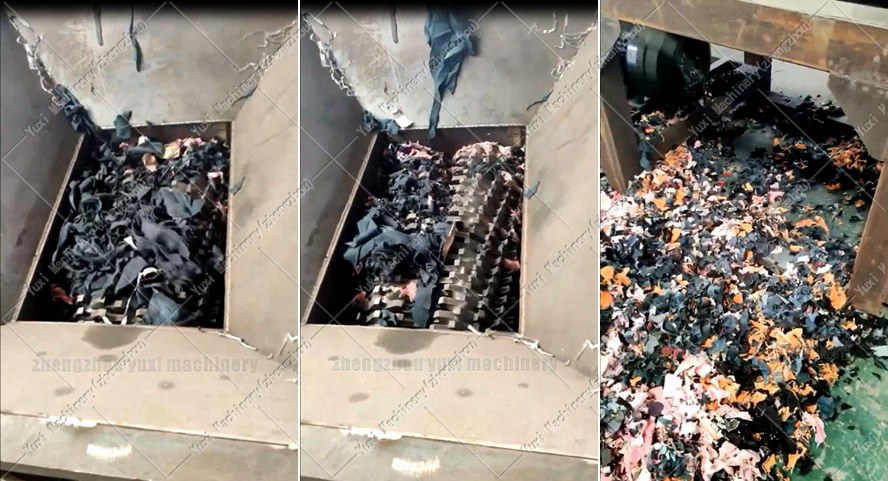

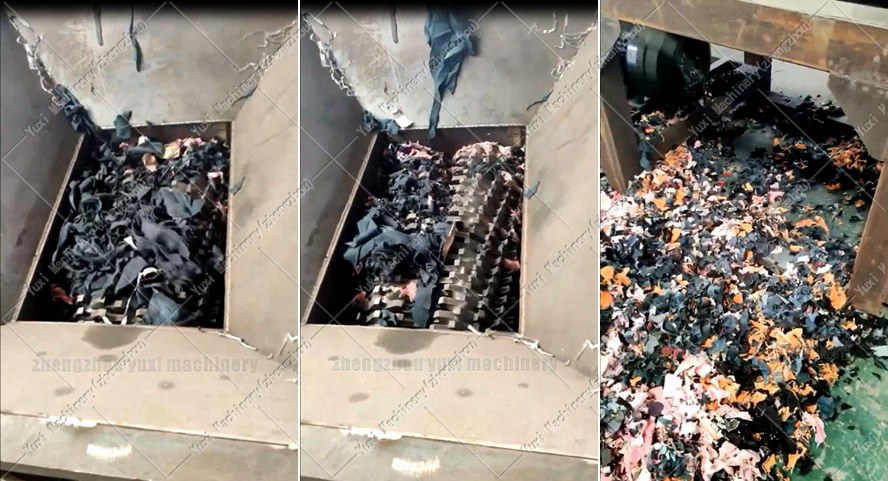

A textile waste shredder is heavy-duty physical processing equipment designed for these materials. Using single-shaft shearing, dual-shaft shredding, or hammer milling, it breaks large, heterogeneous textiles into uniform 5–50mm fragments (adjustable as needed).

It solves 3 core pain points:

1. Massive Volume Reduction: Compresses 1 ton of bulky waste into 1 cubic meter, cutting storage space by 70% and transportation costs by 80%.

2. Waste-to-Resource Conversion: Shredded material can be sold directly to recyclers (e.g., home textile or building material manufacturers), turning "costly waste disposal" into "profitable material sales."

3. Environmental Compliance: Meets "solid waste minimization" regulations, avoiding penalties for improper waste handling.

2. 3 Core Functions of Textile Waste Shredders: Each Saves or Makes You Money (With Real Cases)

1. Efficient Volume Reduction: Turn "Space-Hogging Waste" into "Transport-Friendly Fragments"

How It Works:

Single-shaft shear shredders are the go-to for volume reduction. Their high-strength alloy blades act like scissors, cutting through thick denim (even with zippers/metal buttons) to compress material. Some models add a "compaction device" to further densify fragments into tight blocks.

Real Case:

In 2023, a California apparel OEM generated 2 tons of defective samples/scraps (mostly denim/cotton-linen) daily, occupying 20 sqm of workshop space and costing $120/day for landfill transport.

After installing a 67 HP single-shaft textile shredder:

• 2 tons of waste were compressed into 300kg dense blocks (15% of original volume).

• Haulage frequency dropped from "daily" to "weekly," cutting annual transport costs from $43,800 to $6,257—a $37,543 saving.

2. Material Sorting: Turn "Mixed Waste" into "High-Value Recycled Feedstock"

How It Works:

Advanced models integrate "shredding + screening + material identification" systems: first cut material into small fragments, screen by size via vibration, then use near-infrared spectroscopy to identify materials (e.g., separating cotton from polyester) and collect fragments by type.

Real Case:

A Manchester-based recycled fiber company previously shredded mixed home textiles (cotton duvets, polyester comforters, wool blankets) together, selling fragments for $75/ton.

After upgrading to a dual-shaft shredder with optical sorting in early 2024:

• Daily processing of 10 tons of used home textiles yielded 6 tons of pure cotton (sold to yarn mills for $1,200/ton), 3 tons of polyester (sold to nonwoven producers for $600/ton), and 1 ton of wool (sold to filling manufacturers for $450/ton).

• Daily revenue jumped from $750 to $9,450 (6×$1,200 + 3×$600 + 1×$450), adding over $261,000/month in income.

3. Universal Compatibility: One Machine Handles All Textile Waste (From Silk to Industrial Felt)

How It Works:

Textile waste varies widely in hardness and toughness—silk tears easily, while industrial felt is rigid like cardboard. Modern shredders solve this with "interchangeable working units + adjustable speed/torque":

• For lightweight materials (silk, chiffon): Use blunt blades + low speed to avoid over-shredding.

• For heavy materials (denim, industrial felt): Use sharp blades + high torque for efficient shredding.

• For waste with impurities (garments with metal buttons): Add a "metal separation device" to extract metal fragments post-shredding.

Real Case:

A North Rhine-Westphalia recycling plant previously used 3 separate machines (for silk, denim, industrial felt), incurring high costs and space usage.

After switching to a "multi-module hammer mill" in 2023:

• One machine processed 5 tons of mixed daily waste: silk scraps with "light hammers + low speed," denim with "heavy hammers + high torque," and felt with "alloy hammers + strong vibration."

• Shredded material was sold to home textile, building material, and automotive interior manufacturers. Equipment costs dropped 40%, and labor costs fell by 2/3.

3. How to Choose a Textile Waste Shredder: 4 Key Factors to Avoid Regret

Choosing the right model saves money and maximizes profits—focus on these 4 points:

1. Waste Type:

◦ Single-material waste (e.g., 100% cotton): Single-shaft shear shredders offer the best value.

◦ Blended/multi-material waste: Dual-shaft shredders with sorting capabilities.

◦ Waste with metal/hard impurities: Models with "magnetic/wind separation devices."

2. Daily Processing Capacity:

◦ <1 ton/day: Small shredder (11 kW), $7,000–$13,000.

◦ 1–5 tons/day: Medium shredder (22–37 kW), $25,000–$50,000.

5 tons/day: Industrial shredder (37–75 kW), $60,000–$230,000.

3. Downstream Requirements:

◦ Volume reduction only: 20–50mm fragments (no need for precision).

◦ Resale as feedstock: Confirm fragment size with buyers (e.g., 10mm for home textile filling, 30mm for building insulation) and choose an adjustable-size model.

4. Long-Term Maintenance:

◦ Choose models with easily replaceable blades (cheap models may have welded blades requiring full disassembly to replace).

◦ Choose models with "fault alerts" (e.g., auto-shutdown on motor overload) to reduce repair costs.

4. Using & Maintaining Textile Waste Shredders: 5 Tips to Extend Lifespan by 3+ Years

Many machines fail within 1 year due to improper use—follow these 5 tips for 5–8 years of service:

1. Mandatory Pre-Processing:

Manually remove large metal parts (buckle, zipper pulls) and hard plastics (clothing decorations)—these can chip blades or jam the shaft. Wipe oily industrial textiles before feeding to prevent grease buildup on blades (which reduces cutting efficiency).

2. Uniform, Steady Feeding:

Avoid "dumping half a ton at once"—overloading spikes motor load, causing uneven shredding and burnout. Avoid "feeding sparingly"—idling wastes energy and dulls blades. Use a conveyor belt to feed at a speed matching the machine’s rated capacity.

3. Non-Negotiable Regular Maintenance:

◦ Weekly: Lubricate blade shafts/bearings with high-temperature wear-resistant oil (avoid standard oil, which thickens and jams shafts).

◦ Every 3–6 months: Inspect blade wear—replace if edges are curled or rounded (dull blades increase energy use by 30% and reduce fragment quality).

◦ Monthly: Open the chamber to clear fiber buildup (fiber wrapping around the shaft reduces efficiency).

4. Critical Safety Rules:

◦ Place emergency stop buttons within easy reach of operators.

◦ Never push material by hand—use a plastic pusher.

◦ Do not open the chamber or insert tools during operation.

5. Stock Spare Parts:

Keep 2–3 blade sets and 1 spare bearing on hand—immediate replacement minimizes downtime (losing 1 day of production can cost thousands in lost revenue).

5. Textile Waste Shredder FAQs

1. Can blended fabrics (e.g., cotton-polyester) be shredded and separated?

Yes:

• Shredding only (volume reduction): Standard single-shaft shredders work.

• Material separation: Dual-shaft shredders with optical sorting can split cotton and polyester fragments.

2. Does shredding produce dust or noise?

• Dust: Industrial models include dust collection systems to capture fiber dust, meeting workshop emission limits (≤10mg/m³).

• Noise: Models with noise-dampening enclosures keep noise ≤85 dB (OSHA-compliant, comparable to normal conversation), avoiding workplace disruptions.

3. Is the market for shredded material stable? Will it be hard to sell?

Yes—demand for recycled textile feedstock is growing rapidly:

• Home textile manufacturers use cotton/wool fragments for filling.

• Building material companies use polyester fragments for insulation.

• Automotive manufacturers use felt fragments for interiors.

• Nonwoven producers use mixed fiber fragments for eco-bags.

As long as fragment size and material meet buyer specs, sales are reliable.

4. Is a shredder cost-effective for small businesses? How long until ROI?

Yes, for businesses with ≥0.5 tons/day of waste:

• A $13,000 small shredder typically pays for itself in 1–2 years (via reduced disposal fees + material sales).

• For low-waste businesses (e.g., 0.2 tons/day), share a machine with nearby peers to split costs.

5. Is energy use high? Will electricity bills be expensive?

Energy use varies by model:

• Small shredder (1 ton/day): 11 kW, ~$1.65/hour (at $0.15/kWh industrial rates).

• Medium shredder (5 tons/day): 37 kW, ~$5.55/hour.

Disposal cost savings + material sales far outweigh electricity costs (e.g., a medium shredder’s $44.4 daily electricity bill pales next to thousands in daily revenue from fragment sales).

6. Conclusion: Textile Waste Shredders Are Not "Costs"—They’re "Profit Tools"

Once a "costly burden," textile waste is now a "sellable resource" thanks to shredders—this is the logic of the circular economy.

Choosing the right model (matched to your waste type and capacity) and following proper use/maintenance not only solves waste disposal issues but also adds a new revenue stream from recycled material sales. As environmental regulations tighten and demand for recycled resources grows, textile waste shredders will soon be standard equipment for textile and recycling businesses.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment