Industry Background and Challenges

Textile waste disposal is a crucial part of the global circular economy. Statistics show that over 92 million tons of textile waste are generated worldwide every year, with less than 1% effectively recycled and reused. These wastes not only occupy a large amount of land resources but also cause serious environmental pollution.

Traditional textile waste disposal methods have many problems: low manual sorting efficiency, incomplete crushing affecting subsequent processing, and severe dust pollution. These pain points restrict the development of the textile waste recycling industry.

To address these industry pain points, a new generation of textile waste shredders has emerged, bringing multiple technological breakthroughs:

Intelligent Sorting System: Adopts near-infrared photoelectric identification technology to realize automatic classification of textile wastes of different materials, with a sorting accuracy of up to 98%.

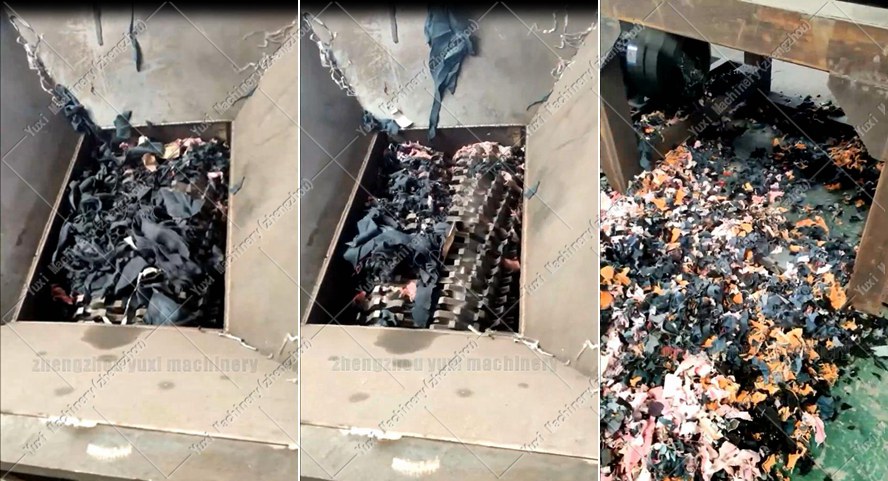

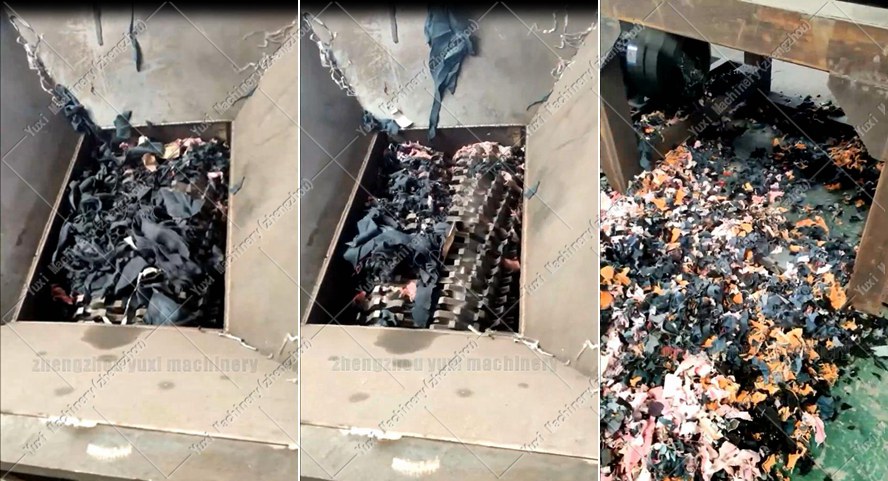

Multi-stage Crushing Technology: The innovative three-stage crushing design can gradually crush large pieces of waste into uniform particles of 0.2-1.2 inches, meeting the needs of different downstream processes.

Intelligent Control System: Achieves full automatic control through PLC and touch screen, which can real-time monitor the equipment operation status and automatically alarm and shut down in case of abnormalities.

Efficient Dust Removal System: Integrates pulse bag dust removal and cyclone dust removal dual systems, with dust emission concentration below 0.03 grains/dscf, far exceeding relevant standards.

Core Equipment Parameters

• Processing Capacity: 1.1-22 short tons per hour, customizable according to requirements

• Motor Power: 40-268 horsepower

• Crushing Particle Size: 0.2-1.2 inches (adjustable)

• Energy Consumption: 13.4-26.8 kWh per short ton

• Noise: ≤85 decibels (3.3 feet away from the equipment)

• Dust Emission: ≤0.03 grains/dscf

Application Scenarios and Cases

Case 1: A Large Textile Industrial Park Waste Treatment Center

The center introduced an intelligent textile waste treatment line equipped with a new generation of textile waste shredders. The system realizes the full-process automation from waste reception, automatic sorting, crushing to packaging.

Results:

• 40% increase in processing efficiency

• 60% reduction in labor costs

• 75% reduction in dust emissions

• Annual processing capacity reaching 110,000 tons

Case 2: A Regenerated Fiber Production Enterprise

The enterprise adopted a customized textile waste shredder, accurately controlling the crushing particle size at 0.3-0.5 inches, providing high-quality raw materials for regenerated fiber production.

Results:

• 25% increase in raw material utilization rate

• Significant improvement in product qualit

• Improved production stability, with 50% reduction in downtime

Equipment Selection and Investment Return Analysis

Selection Suggestions:

1. Select by Processing Scale:

◦ Small-sized: 1.1-5.5 short tons per hour, suitable for small and medium-sized recycling enterprises

◦ Medium-sized: 5.5-11 short tons per hour, suitable for regional recycling centers

◦ Large-sized: 11-22 short tons per hour, suitable for large industrial parks

2. Select by Downstream Requirements:

◦ Regenerated fibers: 0.3-0.5 inches

◦ Non-woven fabrics: 0.6-1.2 inches

◦ Thermal energy recovery: No need for excessive crushing

Investment Return Analysis:

Taking equipment with a processing capacity of 11 short tons per hour as an example:

• Initial investment: Approximately 3-4.5 million US dollars

• Annual operating cost: Approximately 2.25-3 million US dollars

• Annual processing income: Approximately 4.5-6 million US dollars

• Investment payback period: Approximately 2-3 years

Frequently Asked Questions

Q1: Can textile waste shredders handle clothes with metal zippers and buttons?

A: New-generation equipment is usually equipped with magnetic separation and metal detection systems, which can effectively separate metal items. However, it is still recommended to manually sort out a large number of metal accessories first to protect the equipment blades.

Q2: How adaptable is the equipment to different materials?

A: The equipment can handle various materials such as cotton, polyester, blends, and wool, but the crushing parameters vary for different materials. It is recommended to select the appropriate configuration according to the main raw material type.

Q3: What is the maintenance cost of the equipment?

A: Maintenance costs mainly include blade replacement, bearing replacement, and regular maintenance. Generally, the annual maintenance cost is about 5-10% of the original equipment value.

Q4: How to ensure the long-term stable operation of the equipment?

A: In addition to regular maintenance, attention should also be paid to the uniformity of raw materials, avoiding overload operation, and keeping the equipment clean. Establishing a sound equipment management and maintenance system is the key.

Future Development Trends

With the deepening of the circular economy concept and technological progress, textile waste shredders will develop in a more intelligent, efficient, and environmentally friendly direction:

• Intelligence: Introduce AI and big data technologies to realize predictive maintenance and intelligent optimization of equipment

• Modularization: Adopt modular design to facilitate upgrading and maintenance

• High Value-added: Develop more precise crushing technology to meet the raw material needs of high-value-added recycled products

• Low Carbonization: Adopt more energy-saving drive systems and recycling technologies to reduce carbon footprint

As a key equipment connecting textile waste and renewable resources, textile waste shredders will play an increasingly important role in promoting the green transformation of the textile industry and achieving sustainable development goals.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment