Equipment Introduction

Textile waste shredder, also known as waste fabric shredder, is a professional shear crushing equipment designed specifically for processing various types of textile waste. It can efficiently shred waste clothing, waste fabrics, scraps, old clothes, cowhide, fibers, old shoes, carpets, quilts, and other materials into uniform small particles, creating conditions for subsequent recycling.

The equipment is available in various large, medium, and small models to meet the needs of recycling plants of different scales.

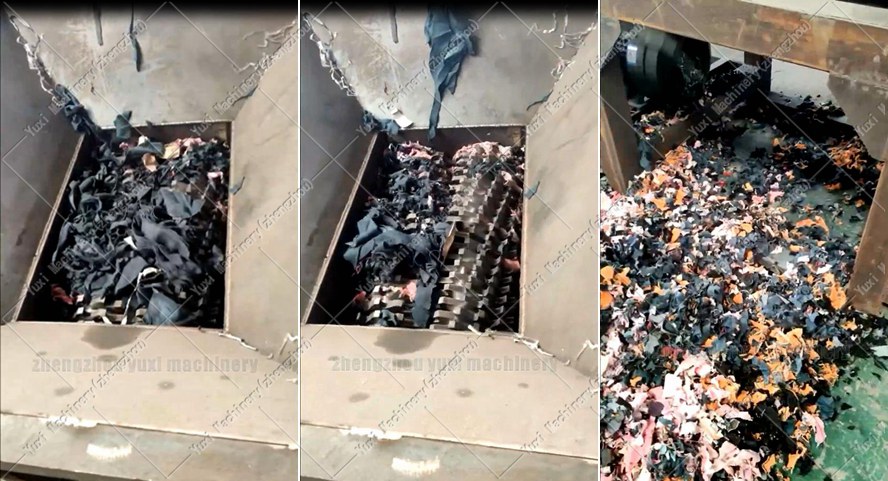

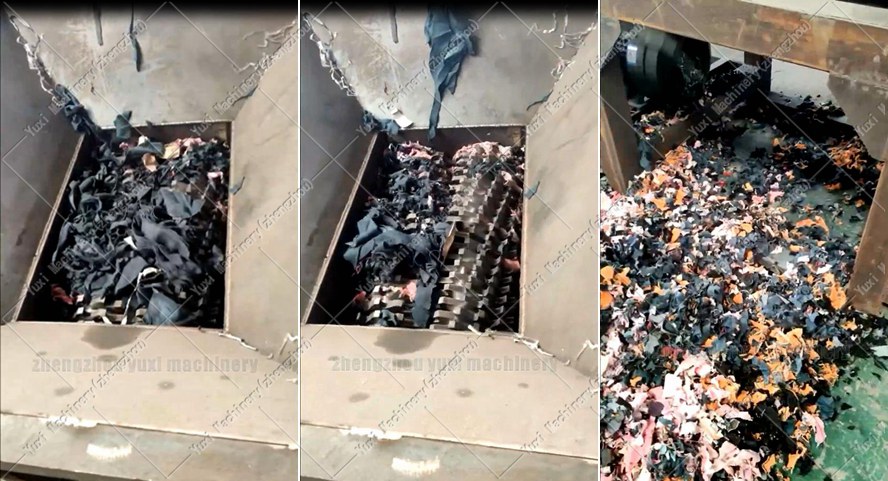

Working Principle

The dual-shaft textile waste shredder mainly relies on the "shear cutting" principle to complete the crushing process:

1. The motor drives the reducer to transmit torque to the moving knife shaft of the shredder

2. The hooks of the moving knife catch the material and tear it apart

3. The blades of the opposite roller cut the waste like scissors

4. The crushed material and pre-screened material are discharged from the bottom

This design ensures efficient crushing of various textile wastes while maintaining equipment stability and durability.

Equipment Features

1. Targeted Design: Especially suitable for crushing soft textile materials, meeting energy-saving and durability requirements

2. Efficient Crushing: High crushing capacity, high output, stable working performance

3. Robust Structure: The frame adopts rectangular tube structure, providing higher strength and stronger stability

4. Durable Components: Uses branded bearings that can withstand greater impact forces

5. Long-Lasting: The shredding chamber is connected by high-strength steel plates and undergoes heat treatment to extend service life

Application Fields

Textile waste shredders are widely used in the following fields:

• Waste recycling plants

• Environmental treatment companies

• Resource recycling companies

Applicable Materials

The equipment is suitable for processing various textile wastes, including:

• Waste cloth heads

• Waste cotton yarn

• Waste clothing

• Cotton

• Chemical fibers

• Linen

• Non-woven fabrics

• Other scraps

Selection and Operation Points

Equipment Selection Guide:

1. Evaluate Waste Type: Different types of textile waste (cotton, polyester, blended, etc.) require different crushing solutions

2. Determine Processing Capacity Requirements: Select the appropriate equipment model based on factory scale and waste generation

3. Consider Space Constraints: Ensure the installation space meets requirements, including feed inlet, discharge outlet, and maintenance space

4. Evaluate Long-Term Costs: In addition to initial investment, consider operating costs, maintenance costs, and energy consumption

Safe Operation Specifications:

• Strictly follow the equipment operation manual

• Operators should receive professional training

• Conduct regular equipment inspections and maintenance

• Ensure good ventilation in the work area

• Correctly use personal protective equipment

Frequently Asked Questions

Q1: Can textile waste shredders handle all types of textile waste?

A: Most textile waste shredders can handle common fabrics such as cotton, polyester, and blends, but for certain special materials (such as clothing with a large number of metal accessories), pre-treatment may be required to remove these accessories.

Q2: What are the uses of shredded textile waste?

A: Shredded textile waste can be used to produce regenerated fibers, non-woven fabrics, filling materials, or as fuel for thermal energy recovery.

Q3: How to choose the appropriate crushing particle size?

A: This depends on the subsequent processing technology. For example, producing regenerated fibers typically requires finer particles (5-10mm), while producing non-woven fabrics may accept larger particles (20-30mm).

Q4: What is the maintenance frequency of textile waste shredders?

A: The maintenance frequency depends on usage intensity and waste type. It is generally recommended to conduct basic inspections once a week, comprehensive maintenance once a month, and replace worn parts once a quarter.

Q5: How much dust is generated during the crushing process? How to control it?

A: The amount of dust depends on the type of waste and the crushing fineness. Modern textile waste shredders are usually equipped with efficient dust removal systems, which can control dust emissions within safe limits.

Textile waste shredders are key equipment for realizing the circular economy in the textile industry. By selecting appropriate equipment, optimizing operating processes, and establishing a sound recycling system, we can significantly reduce the environmental impact of textile waste while creating new economic value.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment