1. Opening: Addressing Pain Points Directly - "Textile Waste Shreds Unevenly and Clogs Machines Easily? Choosing the Right Shredder is the Key"

In textile recycling, "chemical fiber tangles causing equipment shutdown", "cotton fibers damaged after shredding", and "fined for failing dust removal standards" are the most troublesome issues for practitioners. The process details of textile waste shredders (and supporting textile撕碎 machines) directly determine the efficiency of waste recycling and the profit of production lines. Below, we will dissect the core technical logic of the equipment from principles to selection to help you avoid pitfalls in purchasing and using.

2. Operation Logic of Textile Waste Shredders: The Golden Process of "Pretreatment → Shredding → Resource Utilization"

Textile waste is a flexible solid waste of cotton/chemical fiber/blended fabrics, and shredders need to meet the triple requirements of "shredding evenly + no tangling + adapting to subsequent recycling". The process chain can be divided into:

1. Pretreatment: "Remove Impurities and Classify" Before "Shredding"

It is necessary to first sort manually or mechanically to remove metal buttons, zippers (to prevent damage to cutters), and then classify by material into pure cotton, chemical fiber, and blended fabrics - this step can increase subsequent shredding efficiency by 30% and avoid equipment jamming.

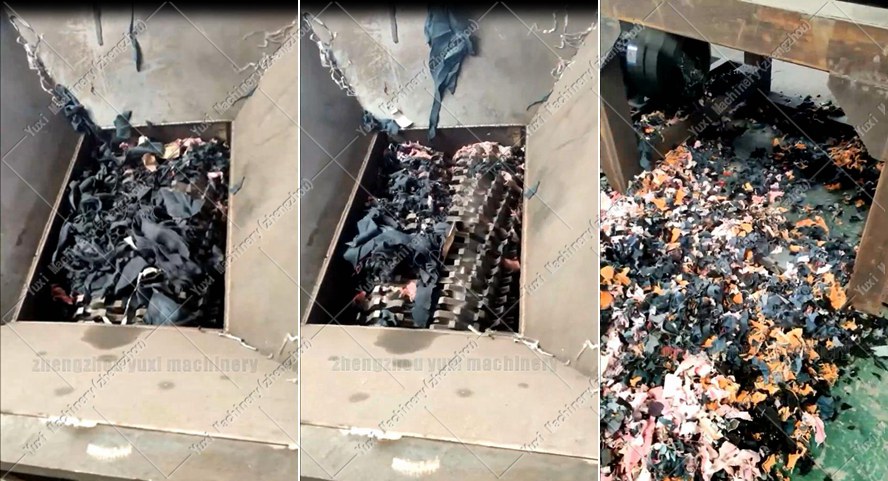

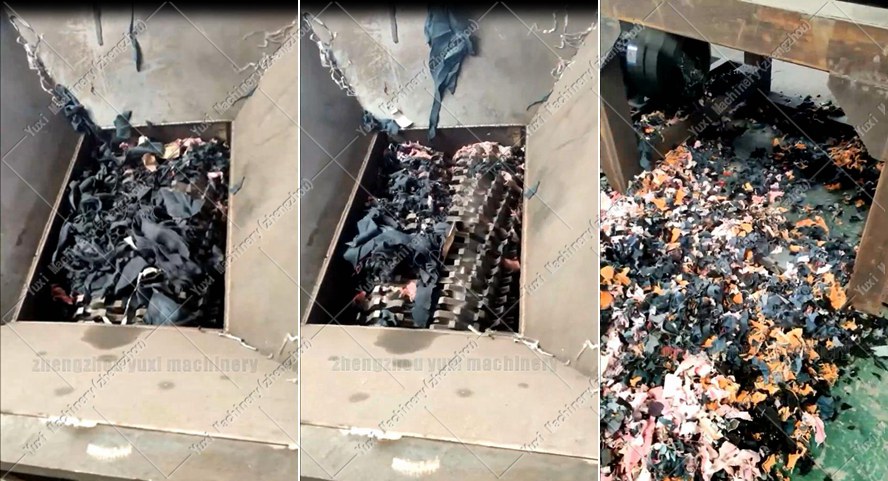

2. Main Shredding: Choose the Right Shredding Method According to Material

Shredders perform "coarse shredding → fine shredding" on pretreated fabrics, with the core being to control particle size:

◦ For low-toughness fabrics such as pure cotton: Use a hammer shredder, which shreds and crushes through the "impact + tearing force" of high-speed hammers, with a final particle size of 10-30mm, suitable for recycled spinning;

◦ For high-toughness fabrics such as chemical fibers: Use a shear shredder, where the moving and fixed knives mesh precisely (gap 0.1-0.5mm) for shearing, with a particle size of 10-50mm, avoiding fiber tangling;

The particle size should not be too fine (which will damage fibers and reduce recycling value) or too coarse (which affects subsequent opening or granulation).

3. Resource Utilization: Determine Recycling Value After Shredding

The shredded fibers enter the "opening → spinning" process for pure cotton and the "granulation → recycled chemical fiber" process for chemical fibers, which is also the ultimate goal of the shredder process.

3. Core Configuration Details: Avoiding Pitfalls in Three Dimensions of "Anti-Tangling, Wear Resistance, and Intelligence"

1. Anti-Tangling Design: Solving the "Age-Old Problem" of Chemical Fiber Shredding

Textile fibers are prone to tangling, so shredders must have targeted designs:

• Shredding chamber: Smooth inner wall + "anti-tangling grooves", and equipped with spiral guide vanes, combined with airflow (500-2000 cubic feet per minute) to guide fibers toward the discharge port without accumulation;

• Cutters: Shear shredders use "stepped moving knives + serrated fixed knives" to avoid "slip cutting" of chemical fibers; hammer shredders use "reversible hammers" that can be flipped for use after wear, saving consumable costs.

2. Wear Resistance and Power: Ensuring Production Capacity Doesn't "Break Down"

• Cutter material: Choose ASTM D2 high-carbon steel or cemented carbide, with cutting edges subjected to high-frequency quenching (hardness above HRC60), usable for 2000-5000 hours when processing pure cotton and 1500-3000 hours for chemical fibers;

• Power system: Motor power ranges from 40-200 HP, equipped with a soft starter (to avoid grid impact), and a torque sensor - once fibers tangle the machine, it automatically reduces speed or reverses to discharge materials, preventing motor burnout.

3. Connection with Textile Shredding Machines: "Coarse Shredding + Fine Shredding" Improves Efficiency

Textile shredding machines are "front-end helpers" suitable for processing large pieces of fabric (such as used clothing rolls):

• Use a double-shaft knife set to tear large pieces of fabric into 100-300mm pieces, then feed them into the shredder, reducing the risk of feeding tangling in the shredder;

• When recycling high-purity waste such as medical waste cloth and high-end clothing, shredding first and then fine shredding can increase fiber integrity by 15%, resulting in better quality recycled yarn.

4. Processing and Component Details: These "Small Designs" Determine Equipment Durability

1. Shredding Chamber Liner: Wear-Resistant and Easy to Replace

For trace impurities in fabrics (such as printed metal powder), the liner uses ASTM A48 Class 30 wear-resistant cast iron or ceramic patches, and key wear areas are made "modular", allowing direct replacement when damaged without disassembling the entire machine, saving maintenance time.

2. Discharge and Impurity Removal: Protecting Subsequent Equipment

• The discharge port is equipped with a magnetic separator (magnetic field ≥ 11200 Gauss) to remove metal impurities a second time, avoiding scratches on opening or spinning machines;

• Equipped with a vibration screening device, unqualified coarse materials are automatically returned for re-shredding, ensuring the discharge particle size deviation is ≤ 5mm for smoother subsequent processes.

3. Dust Removal Configuration: Comply with Regulations and Avoid Fines

Textile shredding produces fiber flocs, so a pulse bag dust collector (filtration accuracy ≤ 1 micron) must be equipped, and negative pressure sealing covers are added at the feed and discharge ports to control workshop dust within 10 mg/m³, meeting the emission standards of the US EPA.

5. Selection and Compliance: Choose According to Needs, Avoid Wasting Money

1. Selection: Based on Materials + Production Capacity

• Choose models according to materials:

◦ Pure cotton: Hammer shredder (e.g., FWS-600, 2.2-6.6 short tons per hour);

◦ Chemical fiber: Shear shredder (e.g., FWS-1200, 17.6-33 short tons per hour);

◦ Blended fabrics: Hammer-shear composite type (e.g., FWS-800, 6.6-17.6 short tons per hour).

• Choose scale according to production capacity:

◦ Small recycling plants (annual processing < 11023 tons): Choose models with 2.2-11 short tons per hour;

◦ Large bases (annual processing > 44092 tons): Choose customized models with 22-66 short tons per hour.

2. Equipment Parameter Reference (FWS Series)

| Model | Motor Power (HP) | Processing Capacity (short tons/hour) | Feed Size (inches) | Discharge Particle Size (inches) | Equipment Weight (tons) | Overall Dimensions (inches) |

| FWS-600 | 50 | 2.2-6.6 | ≤31.5×31.5 | 0.4-1.2 | 6.17 | 118×59×79 |

| FWS-800 | 75 | 6.6-17.6 | ≤39.4×39.4 | 0.4-1.6 | 9.98 | 157×71×87 |

| FWS-1200 | 120 | 17.6-33 | ≤47.2×47.2 | 0.4-2 | 18.07 | 197×79×100 |

3. Compliance Points: Avoid Stepping on Policy Red Lines

• General textile recycling: Comply with the US Resource Conservation and Recovery Act (RCRA) or the EU Waste Framework Directive (WFD);

• Hazardous waste such as medical waste cloth: Must obtain a "Hazardous Waste Operating Permit", and dust and noise reduction facilities must pass environmental acceptance.

6. FAQ: 3 Most Concerned Questions of Practitioners

1. "Can elastic fabrics containing spandex be shredded?"

Yes, but choose a shear shredder, adjust the gap between moving and fixed knives to within 0.2mm, reduce the feeding speed by 20% compared to conventional fabrics, and sharpen the knives every 200 hours of operation to avoid equipment overload.

2. "What if the cutters become blunt? Can I repair them myself?"

It is recommended to find the manufacturer or a professional organization for sharpening (to ensure cutting edge accuracy); self-sharpening can easily damage the knife shape, accelerating wear instead. If they are reversible hammers, they can be flipped for continued use without sharpening.

3. "Small textile mills buying for the first time, how to choose with limited budget?"

First, complete the solid waste treatment qualifications, reserve space for sorting, shredding, and dust removal in the site, and ensure the ground is slip-resistant and wear-resistant (to avoid fiber accumulation and slipping); when choosing equipment, prioritize manufacturers that offer "trial shredding services", test the shredding effect of your own waste on-site, and then decide whether to buy a second-hand small model (such as FWS-600) or new equipment to reduce initial investment.

Conclusion: Choose the Right Equipment to Turn Textile Waste into "Treasure"

The details of textile waste shredders directly affect recycling profits - anti-tangling design can reduce downtime, wear-resistant cutters can lower consumable costs, and compliant configurations can avoid fines. Whether you are a textile mill dealing with leftover materials or a recycler engaged in resource utilization, you must clarify the material type and production capacity before choosing equipment. It is best to visit the manufacturer's case production line to see the actual operation effect before deciding on cooperation.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment