In scrap metal recycling, "hard steel damaging cutters", "uneven shredding of aluminum/copper affecting smelting", and "fined for failing dust removal standards" are the most frustrating issues. The details of scrap metal shredders (including small models) directly determine recycling profits and whether the production line can operate profitably. Below, we will dissect the equipment’s know-how from principles to selection to help you avoid pitfalls in purchasing and production.

1. Operation Logic of Scrap Metal Shredders: The Golden Process of "Pretreatment → Shredding → Selling at a Good Price"

Scrap metal is a hard and mixed solid waste (steel, aluminum, copper + plastic/rubber impurities), and shredders must simultaneously achieve "shreddable + easy sorting + recyclable for smelting". The process has three steps:

1. Pretreatment: Clean Impurities and Classify First

Manual/mechanical sorting is necessary to remove non-metallic impurities like rubber and plastic (otherwise they damage cutters and cause pollution), and then separate steel, aluminum, and copper — doing this can increase subsequent shredding efficiency by 30% and avoid equipment jams.

2. Main Shredding: Choose the Right Shredding Method Based on Material

Shredders perform "coarse shredding → fine shredding" on metals, with the core being to control particle size:

◦ Hard steel (waste rails, I-beams): Use a hammer shredder, where high-speed hammers "smash + shear" to shred, with the final particle size controlled at 0.2-2 inches, suitable for steel mills’ recycling;

◦ Soft aluminum/copper (waste aluminum doors, old copper pipes): Use a roller shredder, where double rollers squeeze to shred, also controlling particle size at 0.2-2 inches for smelting in aluminum/copper plants;

Particle size must not be too fine (damaging metal structure and reducing value) or too coarse (rejected by steel/aluminum plants, requiring rework).

3. Resource Utilization: Sell at a High Price After Shredding

Shredded metals enter magnetic separation and eddy current separation machines to separate steel and aluminum/copper, which are directly sold to steel/aluminum plants — this is the ultimate value of shredders: turning waste metal from "scrap" into "raw material".

2. Core Configuration Details: Avoiding Pitfalls in Three Dimensions of "Wear Resistance, Anti-Jam, and Small Models"

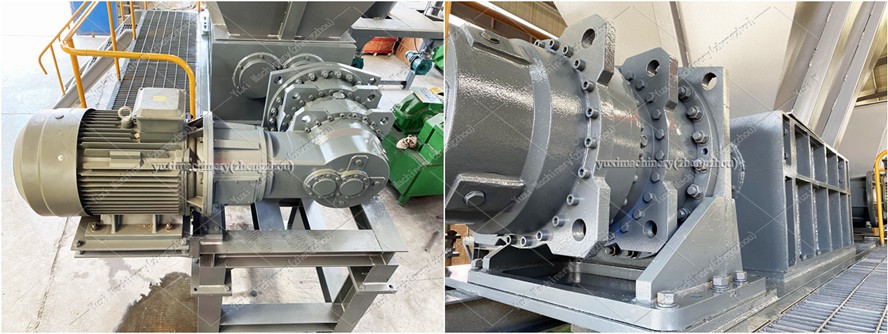

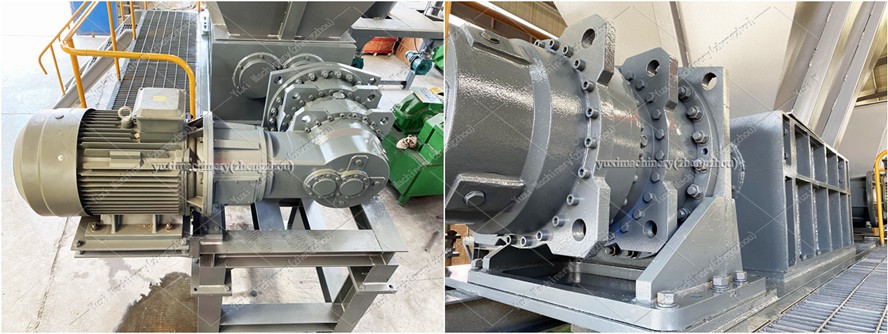

1. Wear-Resistance Design: "Hard Skills" for Handling Hard Steel

Scrap metal is extremely hard, so shredders must have wear-resistance enhancements:

• Shredding chamber: Lined with ASTM A128 Class 3 manganese steel (thickness 2-4 inches) or composite wear-resistant alloy; high-end models use "modular liners" that can be replaced individually without disassembling the entire machine;

• Cutters/Hammers:

◦ Material: Choose AISI H13 high-chromium alloy or tungsten carbide (hardness HRC60+); hammers in hammer shredders are "staggered" to prevent metal accumulation in the chamber; teeth of roller shredders are "trapezoidal" for better metal gripping during shredding.

2. Anti-Jam and Power: Ensuring Production Capacity Doesn’t "Break Down"

• Power: Motor power must be sufficient (150-550 HP), equipped with a hydraulic coupler for "soft start" (to avoid damaging the power grid), and a torque sensor — when metal jams occur, it automatically reduces speed or reverses to discharge materials, preventing motor burnout;

• Intelligent Control: PLC system can "predict jams" by combining current, speed, and other data; for hard and mixed metals, it automatically adjusts shredding parameters (e.g., hammer speed, roller gap) without manual repeated adjustments.

3. Small Scrap Metal Shredders: "Magic Tool" for Small Workshops/Fine Recycling

Small models are "flexible players" suitable for small-batch or fine shredding:

• Structure: Single/double shaft shredding chamber, low speed and high torque (motor 40-100 HP), shredding cans and small steel bars into 0.4-4 inch pieces to reduce feeding troubles for large models;

• Application Scenarios:

◦ Auto repair shops/small recycling points: Can operate independently, occupying less than 100 square feet, shredding waste aluminum doors to below 0.8 inches for direct sale to aluminum plants, saving transportation and rework costs;

◦ Front end of large production lines: First coarsely shred with small models, then finely shred with large models, enabling the entire line to handle more metal types.

3. Processing and Component Details: These "Small Designs" Determine Equipment Durability

1. Main Shaft and Bearings: "Backbone" for Withstanding Heavy Loads

• Main shaft: Forged from ASTM A434 alloy steel, undergo quenching-tempering and precision grinding, ensuring no deformation under high torque;

• Bearings: Choose spherical roller bearings (232 series), which can withstand 2-3 times more load than ordinary bearings and automatically compensate for minor shaft deflection, reducing damage from metal impact.

2. Discharge and Impurity Removal: "Filter" for Protecting Downstream Equipment

• Discharge port: Equipped with a strong magnetic separator (magnetic field ≥ 17,000 Gauss) to remove residual plastic/rubber impurities in shredded materials, avoiding damage to steel/aluminum plant equipment;

• Equipped with a vibrating screen to sieve out unqualified coarse materials and send them back to the shredder for re-shredding, ensuring discharge particle size deviation ≤ 0.2 inches, making downstream buyers more willing to purchase.

3. Environmental Protection and Safety: "Umbrella" for Compliant Profit-Making

• Dust removal: Equipped with a pulse bag dust collector (filtration accuracy ≤ 0.0002 inches), with negative pressure sealing covers at feed/discharge ports, controlling workshop dust within 0.0006 lb/ft³ to meet US EPA standards and avoid environmental fines;

• Safety: Equipped with emergency stop buttons and safety interlocks; in case of misoperation, pressing the button stops the machine immediately; some models have "split-type cabinets" for easy disassembly of knife shafts and blade replacement, reducing downtime for maintenance.

4. Selection and Compliance: Choose Based on Needs, Avoid Wasting Money

1. Selection: Based on Materials + Production Capacity

• Choose models based on materials:

◦ Hard steel (rails, I-beams): Hammer shredders (e.g., FJS-1200, shredding 44-88 short tons per hour);

◦ Soft aluminum/copper (aluminum doors, old copper pipes): Roller shredders (e.g., GJS-800, shredding 22-55 short tons per hour);

◦ Small mixed materials (cans, waste wires): Small models (e.g., XJS-400, shredding 2.2-11 short tons per hour).

• Choose scale based on production capacity:

◦ Small recycling plants (annual recovery < 11,023 short tons): Choose models shredding 11-44 short tons per hour;

◦ Large bases (annual recovery > 44,092 short tons): Choose customized models shredding 88-220 short tons per hour.

2. Equipment Parameter Reference (FJS Series, Units Adapted to Overseas Usage)

| Model | Motor Power (HP) | Processing Capacity per Hour (short tons) | Feed Size (inches) | Discharge Particle Size (inches) | Equipment Weight (short tons) | Overall Dimensions (inches) |

| XJS-400 | 50 | 2.2-11 | ≤8×8 | 0.2-0.8 | 7.06 | 118×59×87 |

| FJS-800 | 100 | 11-44 | ≤16×16 | 0.2-1.2 | 18.74 | 177×79×98 |

| FJS-1200 | 180 | 44-88 | ≤24×24 | 0.2-1.6 | 34.79 | 236×98×118 |

3. Compliance Points: Avoid Stepping on Policy Red Lines

• Ordinary scrap metal: Comply with the US Resource Conservation and Recovery Act (RCRA) or EU Waste Framework Directive (WFD);

• Hazardous waste (e.g., waste battery casings): Must obtain a "Hazardous Waste Operating Permit", and dust/noise reduction equipment must pass environmental acceptance.

5. FAQ: 3 Most Concerned Questions for Recyclers

1. "Can painted waste steel be shredded?"

Yes, but prevent paint pollution. Either choose a shredder with a "high-temperature paint removal chamber" or remove paint before shredding; after shredding, use magnetic separation + air separation to separate paint powder and metal, avoiding pollution to downstream manufacturers.

2. "How often do cutters in small models need replacement?"

Depends on the metal being shredded. For soft materials like waste aluminum, AISI H13 cutters can last 5,000-10,000 hours; for hard steel, lifespan shortens to 2,000-5,000 hours, and regular sharpening can extend it by 30%.

3. "First-time purchase for personal workshops with limited budget, how to choose?"

First complete recycling qualifications, reserve space for sorting, shredding, and dust removal (hardened and slip-resistant ground); ask manufacturers for "trial shredding" to test your own scrap metal on-site, and prioritize small models (e.g., XJS-400) for low initial investment and gradual expansion.

Conclusion: Choose the Right Shredder to "Earn More" in Scrap Metal Recycling

The details of scrap metal shredders directly affect your profits — wear-resistance design reduces cutter replacement, anti-jam systems reduce downtime, and small models enable small workshops to enter the industry. Whether you are a large processor or a start-up recycling point, clarify materials and production capacity before choosing equipment, and it’s best to visit manufacturers’ actual production lines to check results before deciding on cooperation.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment