In scrap metal recycling, "loose waste takes up space and transportation costs eat up profits", "mixed metals get low prices from steel mills", and "heavy fines for failing environmental compliance" are the most frustrating problems. The process details of metal balers directly determine whether you can "press waste into money". Below, we will dissect the equipment's know-how from principles to selection to help you avoid pitfalls in purchasing and operation.

1. Operation Logic of Metal Balers: The Golden Process of "Pretreatment → Compression → Selling at a High Price"

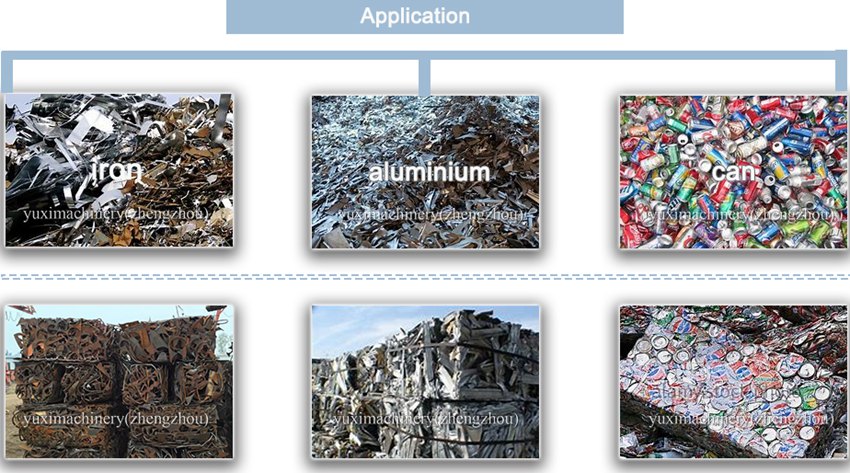

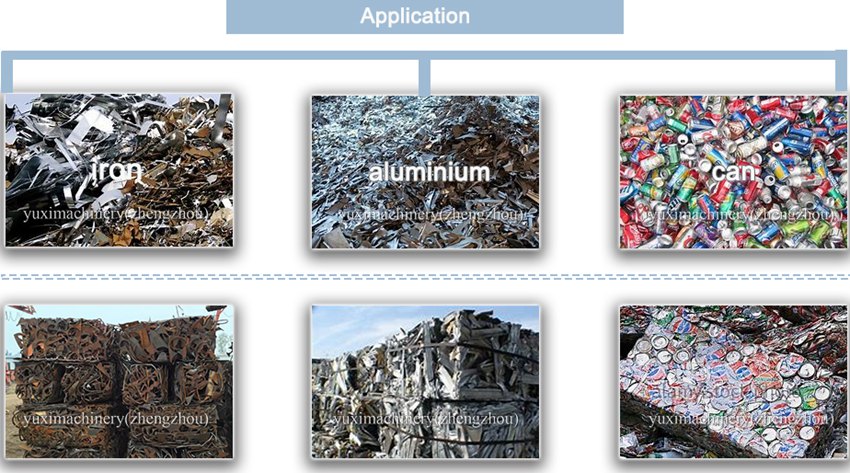

Scrap metal is loose waste of steel/aluminum/copper, and balers must simultaneously achieve "tight compression + easy transportation + favored by steel mills". The process has three steps:

1. Pretreatment: Clean Impurities and Classify Before Starting

Manual/mechanical sorting is necessary to remove "garbage" such as rubber and plastic (otherwise it will damage equipment and pollute metals), and then separate steel, aluminum, and copper — doing this can increase subsequent compression efficiency by 40% and make steel mills willing to buy your goods at a high price.

2. Main Compression: Choose the Right Compression Method According to Waste

Balers perform "preliminary consolidation → shaping and baling" on pretreated metals, with the core being to control the bale:

◦ Fine loose waste (steel chips, aluminum shavings): Use a hydraulic metal baler, which presses waste into bales with a density of 3-4 short tons per cubic yard through a high-pressure hydraulic cylinder. Steel mills love this kind of "regular-shaped and high-density" raw material;

◦ Large-sized waste (old steel, scrapped auto parts): Use a horizontal metal baler, where the horizontal pusher and pressure head work together, and the bale size is adapted to the transport carriage, reducing transportation trips by more than 30% and saving a lot of freight costs;

Bales should not be too loose (they will scatter during transportation, wasting money and polluting) or compressed too hard (which will damage metals and be rejected by steel mills).

3. Resource Utilization: Earn Price Difference Directly After Bal ing

After baling, steel bales are sent to steel mills and aluminum bales to aluminum plants. Because they are "regular and dense", the recycling price is 10%-15% higher than that of loose waste. This is the core value of balers — turning scrap metal from "waste" into "raw material that steel mills scramble for".

2. Core Configuration Details: Avoiding Pitfalls in Three Dimensions of "Hydraulics, Molds, and Small Models"

1. Hydraulics and Pressure Head: "Hard Strength" to Crush Hard Metals

Scrap metal has high hardness, so the hydraulic system of the baler must have "sufficient pressure and strong wear resistance":

• Hydraulic system:

Use a high-pressure plunger pump (pressure 2300-4600 psi) + accumulator, and the flow rate must match the action rhythm of the pressure head (ensuring the pressure head presses and retracts quickly without delaying work); equipped with an electro-hydraulic proportional valve to precisely control pressure and speed to avoid equipment damage.

• Pressure head and mold:

◦ The pressure head is made of AISI 4340 alloy steel (quenched and tempered + nitrided, hardness HRC45+), and the mold is lined with ASTM A128 Class 3 manganese steel wear-resistant plate (thickness ≥ 0.8 inches), which can be replaced individually when worn;

◦ The mold is designed for "quick change" and can adjust the size according to the type of waste (narrow mold for steel chips, wide mold for old steel), with particularly flexible adaptability.

2. Feeding and Pushing: Ensure Continuous Production

• Feeding system:

Use a chain conveyor or grabbing feeding mechanism to evenly feed loose waste into the feed port, and the feeding speed must match the cycle of the pressure head (for example, if the pressure head completes one compression every 2 minutes, the feeding amount is transported according to the corresponding bale weight); a "grid baffle" is set at the feed port to block oversized waste (preventing jamming and delaying production).

• Pushing system:

The horizontal baler pushes waste into the compression chamber by a hydraulic push cylinder; the vertical baler uses "hopper self-weight + auxiliary push cylinder" for feeding, and the pushing force is 1/3-1/2 of the pressure head pressure to ensure waste is consolidated before compression.

3. Small Metal Baler: A "Tool" for Small Workshops/Fine Recycling

In scenarios of small-batch recycling and limited space, small metal balers are key for "flexible pretreatment/independent operation":

• Structural design: Adopt "vertical single-cylinder + small hopper" with a hydraulic pressure of 2300-2900 psi, which can compress small-sized waste such as aluminum shavings and copper wires into compact bales;

• Application scenarios:

◦ Auto repair shops and small recycling points: Covering an area of less than 100 square feet with a motor power of 20-40 HP, they can press waste such as old aluminum doors and windows into bales and directly supply nearby aluminum plants, saving intermediate transportation and rework costs;

◦ Front end of large production lines: First pre-compress ultra-loose waste (such as steel shavings), and then send it to large machines for final baling to improve the processing capacity of the entire production line for different forms of waste.

3. Processing and Component Details: These "Small Designs" Determine Equipment Durability

1. Body and Sealing: "Skeleton" to Withstand High Pressure

• Body: Made of ASTM A572 Grade 50 steel plate for overall welding, and the internal stress is eliminated through "annealing + aging" process to ensure no deformation during high-pressure compression; key stress areas (such as hydraulic cylinder supports) adopt a "forging + welding" composite structure to enhance bearing capacity.

• Sealing system: The hydraulic cylinder is equipped with a combined sealing ring (Glyd ring + dust ring), suitable for high-pressure and high-speed working conditions to prevent hydraulic oil leakage; a lip seal is set at the contact between the compression chamber and the outside to prevent metal chips from entering the equipment.

2. Electrical and Safety: "Umbrella" for Compliant Production

• Electrical control:

Equipped with a PLC control system, integrated with pressure and displacement sensors, it monitors the pressure head status in real time and realizes the cyclic operation of "automatic feeding → compression → bale pushing → unloading"; a touch screen HMI is configured to flexibly set parameters such as compression pressure and bale size.

• Safety protection:

The equipment is equipped with an emergency stop button and photoelectric guardrail, which automatically stops when personnel approach dangerous areas; at the same time, an overpressure protection valve is set, which automatically relieves pressure when the hydraulic pressure exceeds 5100 psi to prevent equipment overload damage.

3. Environmental Configuration: "Defense Line" to Avoid Environmental Fines

• Dust removal design: A suction hood + bag filter is set above the feed port to efficiently collect metal dust raised during compression (dust removal efficiency ≥ 99%), ensuring the workshop dust concentration meets the US EPA standard (≤ 0.0006 lb/cubic foot);

• Noise reduction measures: Sound insulation covers and shock pads are added to noise sources such as hydraulic pumps and conveyors to control the equipment noise below 85 dB(A), meeting the noise requirements of industrial sites.

4. Selection and Compliance: Choose According to Needs to Avoid Wasting Money

1. Selection Basis: Match Waste, Capacity, and Site

• Waste type matching:

◦ Fine loose waste (steel chips, aluminum shavings, etc.): Prioritize hydraulic metal balers, which can press waste into high-density bales to meet the raw material needs of steel mills;

◦ Large-sized waste (old steel, scrapped auto parts, etc.): Optional horizontal metal balers, whose bale size is adapted to the transport carriage, greatly reducing transportation costs;

◦ Small-volume mixed waste (small aluminum shavings, copper边角料, etc.): Choose small metal balers to meet the recycling needs of small capacity and small sites.

• Capacity and site matching:

◦ Small recycling plants (annual processing volume < 22,046 short tons): Choose small-capacity models, balancing cost and efficiency;

◦ Large-scale resource bases (annual processing volume > 110,230 short tons): Choose large-capacity customized models to meet large-scale recycling needs;

◦ Space-constrained scenarios: Prioritize hydraulic metal balers that are "easy to install and do not require a foundation", and can be adapted to diesel power when there is no power supply.

2. Compliance Points: Avoid Stepping on Policy Red Lines

• General scrap metal recycling: Must comply with regulations such as the US Resource Conservation and Recovery Act (RCRA) or the EU Waste Framework Directive (WFD);

• Hazardous waste recycling (such as waste battery casings, oily scrap metal): Must obtain a "Hazardous Waste Operating Permit", and the dust removal and noise reduction facilities of the baler production line must pass environmental acceptance, and the oil content of metal bales must be ≤ 0.5%.

5. FAQ: 3 Most Concerned Questions of Recyclers

1. "Can oily scrap metal be baled?"

Yes, but pollution protection must be done well. When selecting models, prioritize those with "oil collection + filtration system", or add an oil removal process in the pretreatment stage; the baled bales must be degreased by methods such as high-pressure spraying to ensure the oil content ≤ 0.5% and avoid affecting the production of downstream steel mills.

2. "How long is the service life of the mold of small machines?"

The service life varies with material hardness and processing volume: When processing low-hardness metals such as aluminum shavings, ASTM A128 molds can withstand 8,000-12,000 compression cycles; when processing high-hardness metals such as steel chips, the service life is shortened to 5,000-8,000 cycles. Regular surfacing of wear-resistant layers on the mold surface can extend the service life by 30%.

3. "How to choose for the first purchase of a small recycling point with a limited budget?"

Three steps are required:

◦ First, handle the scrap metal recycling qualification (additional hazardous waste qualification is required for hazardous waste involvement);

◦ Plan the site, reserve areas for feeding, baling, and finished product stacking, and do a good job in ground hardening and anti-slip;

◦ Ask manufacturers for "material test baling service", and prioritize small hydraulic metal balers that are "easy to install, do not require a foundation, and support diesel power" to reduce initial investment and site restriction risks.

Conclusion: Choose the Right Baler to "Earn More" in Scrap Metal Recycling

The details of metal balers directly affect how much money you can earn — sufficient hydraulic pressure makes compression tighter and transportation cheaper; wear-resistant molds reduce consumable replacement and downtime; small machines allow small workshops to enter the industry. Whether you are a large processor or a start-up recycling point, you must clarify the waste type, capacity demand, and site conditions before selecting equipment. It is best to conduct on-site inspections of manufacturers' case production lines and deeply evaluate equipment stability and after-sales support to match the long-term development of recycling business.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment