In the business chain of scrap metal recycling and processing, scrap metal shredders for cans are the key equipment that determines "front-end profits + back-end efficiency". This guide translates technical details of the equipment into practical solutions for recycling scenarios, focusing on what recyclers care most about: how to choose, how to use, and how to make profits.

1. First, Understand: How Does a Scrap Metal Shredder for Cans "Eat Waste and Spit Out Profits"?

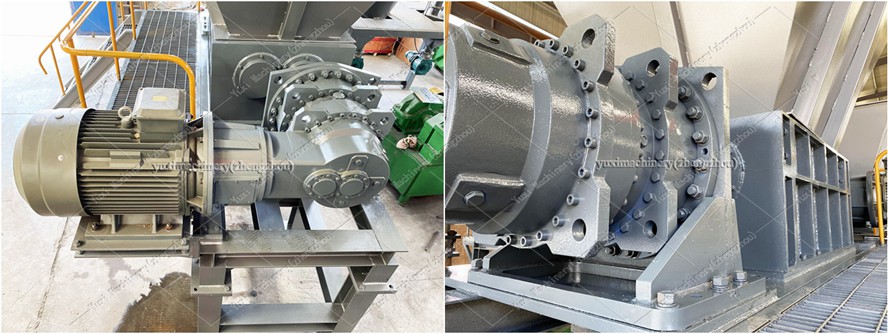

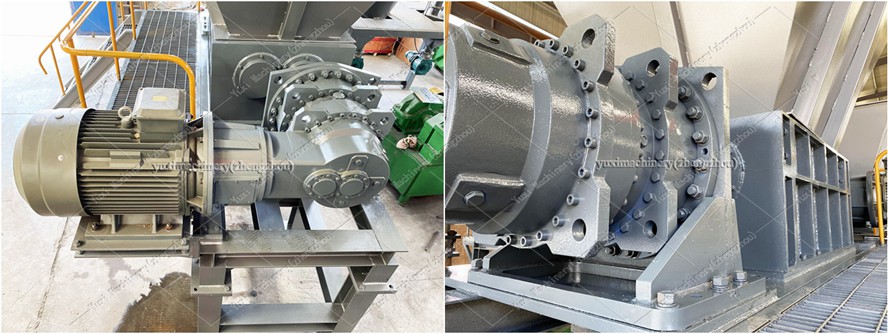

The recycling pain points of can-type scrap metal (such as cans, metal jars, etc.) are "taking up space, difficult to transport, and slow to sort". The double-shaft independent drive structure of the shredder is the key to breaking this situation—two shafts perform "extrusion + shearing + tearing" on the material at different speeds, completely shredding the shell, welds, and other structures of thin metal cans.

Simply put, when the equipment is working, the material will be "forcibly fed" into the shredding chamber, and the spiral cutters on the cutter shaft (made of AISI H13 high-speed steel or D2 tool steel, which is wear-resistant and durable) cut the cans into uniform scraps. The advantage of this design is: low speed and high torque, which neither wears out the cutters due to high speed nor completely shreds the tough thin metal, making subsequent transportation, sorting, and smelting more convenient.

2. Three Professional Configuration Details That Recyclers Should Focus On

1. Cutters: Whether They Can "Chew Hard Bones" Depends Entirely on Them

Cutters are the "profit-making blades" of the shredder and must meet two requirements:

• Material: It must be special steel such as AISI H13/D2, and it must go through vacuum quenching treatment so that it has sufficient wear resistance and strength, and can be repaired after long use;

• Structure: The inner hole of the cutter and the spindle surface are made into a hexagonal shape, so that the force is more uniform and will not wear quickly locally; the cutters are arranged in a spiral line, so there are no dead ends during shredding, and the efficiency is higher.

2. Bearings & Seals: Don’t Let "Small Malfunctions" Delay Profits

The bearings use IP67 protection grade six-layer sealing, which is full of waterproof and dustproof capabilities and can extend the service life of the bearings by 3-5 times. For recyclers, less equipment maintenance means more profits.

3. Control System: Automatic Reversal = Avoid Shutdown

Nowadays, mainstream models are equipped with UL-certified PLC systems, which can automatically start, stop, reverse, and even automatically reverse when overloaded. For example, if cans are piled up and "jammed", the system will automatically return the material and re-shred it without manual shutdown processing. Production never stops, and profits keep coming.

3. "Lightweight Solution" for Small and Medium-Sized Recycling Stations: Small Metal Shredders

If the recycling volume is not particularly large or the site is small, small metal shredders are a more flexible choice:

• Structure: The split-type cabinet made according to ASME standards allows the cutter shaft (including blades, bearings, etc.) to be quickly disassembled for repair, saving time;

• Production Capacity: It can process 400-2000 pounds of scrap metal for cans per hour, and can shred mixed cans, small metal jars, etc., suitable for small-batch and multi-variety recycling scenarios;

• Cost: The price varies according to the configuration (such as cutter material, motor power), which is easy for small and medium-sized recyclers to afford.

4. What "Real Problems" Can This Equipment Solve for Recyclers?

• Volume Reduction to Save Money: Shred can scrap metal into 4-120 inch materials, reducing volume and directly lowering transportation and storage costs;

• Convenient Sorting: The shredded materials are uniform, making subsequent magnetic separation and eddy current separation of metals more efficient;

• Efficient Smelting: Shredded materials are easier to remelt, which can improve the receiving efficiency of smelting plants, and the waste materials of recyclers are also easier to sell.

5. Three Questions Recyclers Must Clarify Before Buying Equipment

(Change the Q&A into more colloquial decision-making questions)

1. How Long Do Cutters Last Before Replacement?

It depends on what kind of cans you shred and how much you shred every day. For example, if you use AISI H13 cutters and continuously shred about 500 tons of thin cans, you have to repair or replace the cutters; if there are hard objects in the cans (such as residual metal), the service time will be reduced by 30%-50%.

2. Can Small Machines Only Shred Cans?

No. They can also shred waste iron fork pallets, small metal barrels, etc., with a thickness of less than 0.4 inches. But you need to pay attention that the feeding size does not exceed the equipment’s requirements (usually 20-40 inches). For thick metal pipes and the like, the shredding efficiency will be lower.

3. Which to Choose Between Double-Shaft and Single-Shaft Models?

Priority is given to double-shaft! The double-shaft is driven independently by two shafts, and the material can be "force-fed" without slipping, so the shredding efficiency is high; moreover, the equipment vibration and noise can be reduced by 20%-30%, which meets the safety operation and maintenance requirements, and workers can also work more safely.

To sum up, scrap metal shredders for cans are the core fulcrum of "cost reduction + efficiency increase" in the scrap metal recycling industry chain. From the double-shaft drive shredding principle to the professional configurations of cutters, seals, and control systems, to the flexible adaptation of small models, every design directly addresses the core needs of recyclers for "volume reduction, efficiency improvement, and cost reduction". For scrap metal recycling practitioners, choosing and using this equipment properly can not only solve the pain points of scrap metal preprocessing but also seize the opportunity of efficiency and profit in the scrap metal recycling business chain.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment