In the fields of textile industry and municipal solid waste treatment, the textile waste shredder (also known as waste fabric shredder or textile shredder) serves as a key equipment for achieving volume reduction and resource utilization of textile waste, and its technical details and application value are worthy of in-depth analysis. The following is a professional elaboration from the dimensions of equipment principle, core structure, technical advantages and related equipment (fabric shredder).

1. Core Principle: The Technical Underlying Logic of Dual-Shaft Shear Shredding

The textile waste shredder (also known as waste fabric shredder, textile crushing equipment) has a core working mechanism based on the "shear-tear" composite shredding principle:

• The power end drives the reducer via a motor to accurately transmit torque to the dual-shaft rotor assembly in the shredding chamber;

• The moving knife hooks on the rotor firmly grasp textile waste (such as old clothes, waste cloth ends) in a "meshing trajectory", and the fixed knives on the opposite roller and the moving knives form a "scissor-like shearing effect" to forcefully cut open the structure of flexible materials;

• The shredded materials are discharged through the bottom screen or pre-screening module, and the discharge particle size can be precisely controlled by adjusting the knife distance and screen aperture (ranging from 5 - 50mm in general).

2. Key Structure: Professional Design Details for Adapting to Textile Waste

In view of the characteristics of textile waste such as "flexibility, multi-fiber, and easy entanglement", the equipment has been strengthened in structure in a targeted manner:

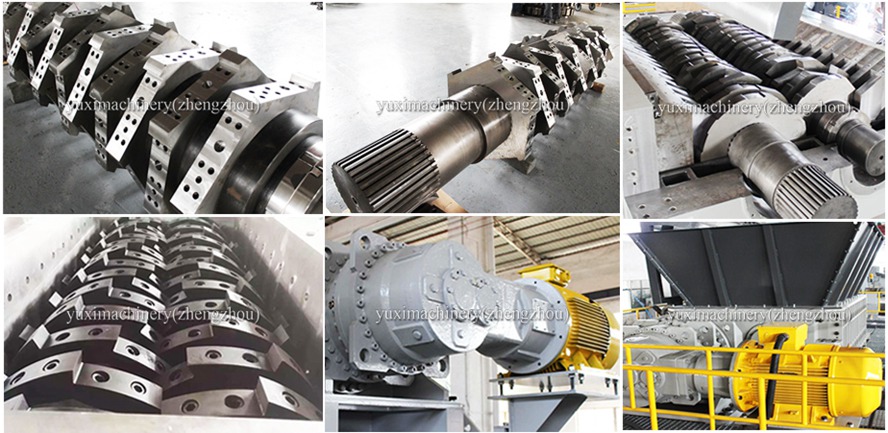

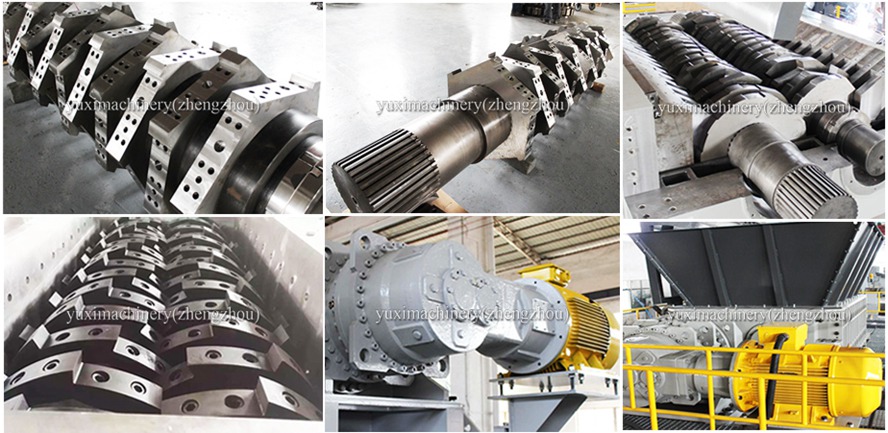

1. Shredding Chamber and Knife System

• The crushing chamber is formed by welding ASTM A572 Grade 50 high-strength hot-rolled steel plates, and the whole is subjected to "quenching + tempering" heat treatment, with the chamber wall hardness reaching above 50HRC, and outstanding wear resistance and impact resistance;

• The knife material is AISI D2 mold steel, which is treated by vacuum quenching process, and the edge hardness is maintained in the range of 58 - 62HRC, ensuring the shearing efficiency and service life for high-toughness fabrics.

2. Transmission and Bearing System

• The main frame is constructed with ASTM A500 Grade C rectangular pipes. Compared with the traditional angle steel welded structure, the strength is increased by 40%, the vibration attenuation rate during equipment operation reaches 90%, and the amplitude is ≤ 0.5mm;

• The bearing is configured as Timken or NTN brand spherical roller bearing, with a rated dynamic load ≥ 200kN, which can withstand the instantaneous impact force of materials during shredding and avoid the risk of shaft system damage.

3. Electrical Control and Safety System

• Equipped with a standard PLC control system, supporting the automatic process of "start-feeding-shredding-stop";

• Built-in "overload protection" and "emergency stop interlock" devices, which automatically stop the machine when materials are entangled or the load exceeds the standard, ensuring the safety of operation and maintenance.

3. Technical Advantages: Core Capabilities to Solve the Pain Points of Textile Waste Treatment

The characteristics of textile waste (such as old clothes, waste fabrics) like "flexibility, multi-fiber, and easy entanglement" are precisely the focal points where the technical advantages of this equipment come into play:

• Material adaptability: The "toothed knife + hook knife" combination structure can effectively prevent fiber materials from entangling the knife shaft, and the shredding efficiency for cotton, chemical fiber, hemp, non-woven fabric and other materials exceeds 95%;

• Energy efficiency and production capacity: With the "low speed, high torque" power configuration (speed ≤ 150r/min), the unit energy consumption (kW·h/t) is reduced by 30% compared with traditional crushers, and the single-machine hourly production capacity covers 1 - 20t (depending on the model specification);

• Stability and durability: The rectangular pipe frame + full welding process enable the equipment to have a mean time between failures (MTBF) ≥ 8000h, and the high-specification configuration of bearings and knives further ensures durability.

4. Related Description of Fabric Shredder (From the Perspective of Process Connection)

The fabric shredder can be regarded as a front-end rough crushing supporting equipment for the textile waste shredder, and the core differences are reflected in:

• The shredded objects focus on "finished fabrics" (such as old clothes, curtains, carpets and other complete fabrics);

• A "wide feed inlet with material拨料辊" is added to the structure to avoid blockage by large pieces of fabric;

• The shredded materials are more suitable for fine resource utilization paths such as "textile recycling and spinning", and the discharge particle size control accuracy is higher (usually ≤ 20mm).

In the textile solid waste treatment production line, the fabric shredder is often used as the "first shredding process" to form a process closed loop with the subsequent textile waste shredder.

5. Application Scenarios and Commercial Value

This equipment precisely serves the needs of the following scenarios:

• Garbage recycling plant: Carry out volume reduction and shredding of textiles in mixed domestic waste to reduce transportation and landfilling costs;

• Environmental protection treatment enterprise: Harmless pretreatment of solid waste in textile parks (such as printing and dyeing residual cloth, garment边角料), in line with environmental compliance requirements;

• Resource recycling company: Resource-oriented pretreatment of old clothes and home textile products. The shredded materials are used in the production of recycled cotton and recycled chemical fiber to increase recycling income.

From the perspective of commercial value, the textile waste shredder can increase the subsequent recycling rate of textile solid waste by more than 60% through "volume reduction pretreatment", while avoiding environmental compliance risks caused by incineration and landfilling.

6. Q&A for Purchasing and Selection

1. What are the core differences between a textile waste shredder and an ordinary plastic shredder?

Answer: The core difference lies in the material adaptation design - the textile waste shredder strengthens the knife anti-entanglement structure and low-speed, high-torque transmission for flexible multi-fiber materials; the plastic shredder is suitable for hard and brittle plastics, with higher speed and sharper knife edge angle.

2. What parameters should be focused on when selecting a model?

Answer: It is necessary to focus on the feed inlet size (matching the maximum size of materials), the number and arrangement of knives (affecting shredding efficiency), the matching degree of motor power and production capacity (avoiding energy waste or insufficient production capacity), and the discharge particle size adjustment range (matching the needs of subsequent processes).

3. Will textile waste containing oil stains and dyes affect the service life of the equipment?

Answer: The equipment knives and chamber walls have been treated with wear-resistant and corrosion-resistant treatments (such as chrome plating on the surface, spraying wear-resistant coatings) to reduce the erosion of oil stains and dyes; however, when dealing with highly polluted waste for a long time, regular cleaning and anti-rust maintenance links need to be added.

4. Can the fabric shredder handle old clothes with metal accessories?

Answer: For models equipped with a "metal detection and avoidance device", they can warn and stop the machine for a small amount of metal accessories; however, old clothes with a large amount of metal need to be manually sorted out in advance, otherwise it is easy to cause knife edge chipping and bearing damage.

In the industrial trend of textile solid waste resource utilization and environmental protection treatment, the textile waste shredder, with its professional shear shredding design and technical advantages of adapting to flexible materials, has become a core equipment for opening up the "textile waste volume reduction-recycling-regeneration" link. Whether from the aspects of material processing efficiency, equipment durability, or the process connection with equipment such as fabric shredders, it accurately responds to the needs of overseas textile recycling and environmental protection industries for efficient and reliable solid waste treatment solutions. For practitioners, choosing this equipment correctly can not only solve the actual pain points of textile waste treatment, but also gain dual values in terms of resource utilization income and environmental compliance.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment