The "Efficiency Pain Points" of the Recycling Business, Solved by This Equipment

Do you often get stuck by these problems in waste metal, waste paper, and plastic recycling?

• Waste is too fluffy, making it impossible to "fill up" the transport truck, and the transportation cost per ton is extremely high;

• Warehouse space is insufficient, and a pile of waste occupies half of the warehouse, with all funds tied up in inventory;

• Steel mills and smelters bargain for the purchase because the waste has irregular shapes, and a large part of the profit is eaten up;

The hydraulic metal baler is a "rigid equipment for the recycling industry" specially designed to solve these pain points. The following will explain the ins and outs of this equipment from three dimensions: technical details, scenario adaptation, and selection logic, helping you choose and use the equipment correctly, and maximize the efficiency of your recycling business.

1. Technical Foundation: Why Can It Make Waste "Compact and Profitable"?

The core of the hydraulic metal baler is the combination logic of "hydraulic power + precision structure", which presses loose waste into "regular hard blocks", directly solving the pain points of transportation, warehousing, and sales.

1.1 Power and Structure: Only with Sufficient Pressure Can Waste "Obey"

• It adopts a hydraulic transmission system, and the power output accuracy is controlled within ±2%, which can accurately adjust the extrusion force according to the hardness of the waste (such as the difference between waste steel and waste aluminum). Simply put, it has strong force when pressing waste steel and will not crush the material when pressing plastic;

• The key structure "pushing cylinder + pushing head" uses a spherical connection design with a matching accuracy of IT7 grade (industrial precision standard), which can not only automatically compensate for installation errors but also extend the service life of vulnerable parts such as oil seals to more than 8000 hours (equivalent to stable use for more than 2 years when used 8 hours a day).

1.2 Installation and Adaptation: No Infrastructure Required, and It Can Work Without Power Supply

• It supports foundation-free installation. The bottom of the equipment is equipped with adjustable support feet. As long as the flatness error of the site is within ±5mm/m (ordinary cement ground can meet the requirement with a little treatment), it can be installed and put into operation on the same day;

• For remote recycling sites without power supply? It supports diesel engine power connection, and is compatible with diesel engines of 15HP~50HP, covering the power needs from small sites to medium-sized factories.

1.3 Safety and Operation: No Fear of Workers' Misoperation, and It Is Safe Even in Narrow Sites

• All dangerous parts are equipped with protective nets, safety switches + emergency stop buttons, complying with the ANSI B11.19 safety standard (general safety specification for the European and American recycling industry), so workers don't have to worry about being crushed or injured by splashing waste during operation;

• The unloading method can be selected from "flip dumping", "push-out from the box", and "manual package picking", and a suitable unloading method can be found even in narrow sites.

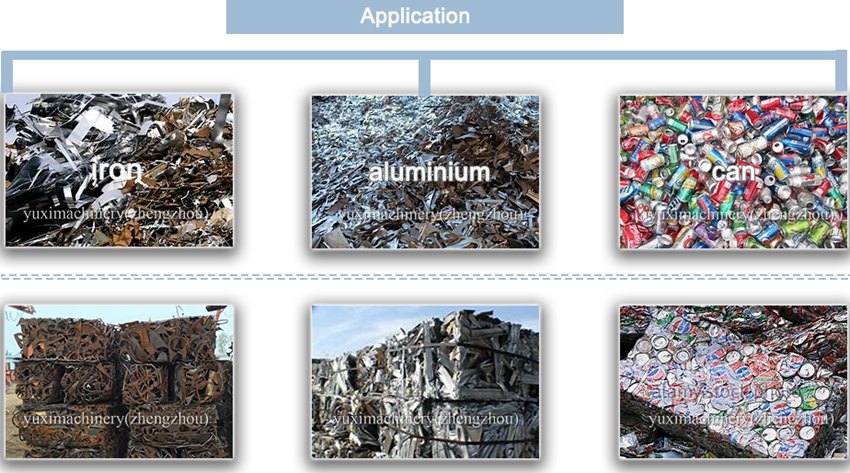

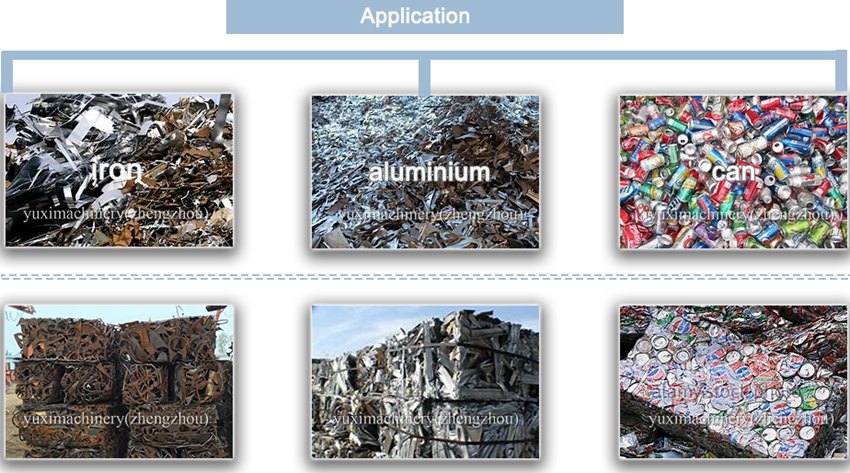

2. Scenario Disassembly: Choose the Corresponding Configuration According to the Type of Waste You Recycle

The "compression requirements" of different wastes vary greatly. Only by choosing the right configuration can the efficiency be doubled.

2.1 Waste Metal Recycling (Upstream of Steel Mills and Metallurgical Plants)

• "Hard waste" such as waste steel and waste iron: Choose a model with a pressing head pressure ≥2000kN, and press the waste to a density ≥3.2t/m³. When steel mills receive the materials, they will not bargain, and the smelting efficiency can be improved because of the "dense furnace charge" (the furnace speed can be 15%~20% faster than that of loose waste);

• "Soft metals" such as waste aluminum and waste copper: Choose a model with a pressure accuracy of ±5bar, and press the waste to a density of more than 2.1t/m³ for aluminum chips and 5.8t/m³ for copper chips, reducing oxidation loss during transportation and making it more convenient for smelting plants to purify.

2.2 Waste Paper, Plastic, and Textile Waste Recycling

• "Light waste" such as old cartons and plastic bottles: Choose a model with a material box volume ≥8m³ and a pressing head stroke ≥1500mm, and the volume reduction rate can be directly increased to more than 90%. The waste that originally filled 1 truck can now fill 10 trucks, reducing transportation costs by 30%;

• "Fluffy waste" such as old fabrics and wheat straw: After pressing, the density reaches more than 0.6t/m³, and the storage volume is directly reduced by 85%. The goods that originally occupied half of the warehouse can now be placed in one corner.

2.3 Scrap Car and Home Appliance Dismantling Recycling

Mixed materials of metal and plastic after dismantling: Choose a model with "pressure mode switching", and the pressure adjustment range covers 50bar~250bar, which can not only press the metal firmly but also not crush the plastic too much, facilitating subsequent classified sale at a high price.

3. Selection & Operation and Maintenance: Guide to Avoid Pitfalls, Buy Right and Use Well to Make Money

3.1 Three Questions for Selection: Think Clearly About These Points Before Finding a Manufacturer

• Ask yourself: "What kind of waste do I mainly press? Hard (waste steel), soft (waste aluminum), or light (waste paper)?" ——Choose models with different pressures and material boxes accordingly;

• Ask about the site: "How large is my recycling site/factory? Can the forklift turn around during unloading?" ——The unloading channel should be at least "the maximum size of the equipment + 1.5m" in width;

• Ask about the scale: "How many tons of waste need to be processed per day?" ——Choose a small model for a daily processing capacity of less than 50 tons, and a large assembly line model for more than 200 tons.

3.2 Two Key Points for Operation and Maintenance: Key Operations for Less Damage and Long Service Life

• Hydraulic oil should be "clean": Measure the oil particle size once a quarter, and the pollution degree should not exceed NAS 8 grade (simply put, there should not be too many impurities in the oil, otherwise the valve group is easy to break);

• Lubrication should be timely: Add lubricating grease meeting the ASTM D4340 standard to the spherical connection part every month to prevent structural parts from wearing, otherwise the equipment will not be used for long.

4. Industry Trends: When Buying Equipment Now, Focus on Configurations That "Can Be Used in the Future"

Nowadays, the hydraulic baler is no longer just about "pressing tightly", but also depends on these two trend configurations:

• Intelligence: Models with IoT modules can monitor pressure, temperature, energy consumption in real time, and can also warn of faults remotely (such as hydraulic oil leakage, pressing head deformation prediction), suitable for bosses who want to build "unmanned recycling factories";

• Greenization: Models equipped with servo hydraulic systems + oil filtration and regeneration devices have an energy consumption 25% lower than traditional models, and the oil recovery rate can reach more than 95%, which is both cost-saving and environmentally friendly, and European and American customers now recognize such "green equipment".

5.Supporting Q&A (Practical Answers to Recyclers' Common Questions)

1. Q: What type of hydraulic metal baler should I choose for recycling hard waste like scrap steel?

A: For hard waste such as scrap steel or iron, select a model with a ram pressure of ≥2000kN. This ensures the compressed waste block reaches a density of ≥3.2t/m³, which meets steel mills’ requirements for furnace charge and avoids price haggling.

2. Q: My recycling site is remote and has no power supply—can a hydraulic metal baler still work there?

A: Yes. Hydraulic metal balers support diesel engine power connection, compatible with diesel engines ranging from 15HP to 50HP. This solves the power supply problem for remote sites and allows normal operation without grid access.

3. Q: How often do I need to maintain the hydraulic metal baler to avoid frequent breakdowns?

A: Focus on two key maintenance tasks: First, test the hydraulic oil cleanliness quarterly (pollution level must not exceed NAS 8 grade) to prevent valve blockages. Second, apply lubricating grease (meeting ASTM D4340 standards) to the spherical connection of the push cylinder and ram monthly to reduce structural wear.

4. Q: I recycle mixed materials (metal + plastic) from scrap car dismantling—what special features should the baler have?

A: Choose a model with a "pressure mode switching" function, where the pressure adjustment range covers 50bar to 250bar. This allows you to adjust the pressure according to material composition: sufficient pressure for metal compaction, and lower pressure to avoid over-crushing plastic, making subsequent sorting and high-price sales easier.

5. Q: What’s the advantage of choosing an intelligent hydraulic metal baler for medium to large recycling factories?

A: Intelligent models integrate IoT modules that monitor real-time data (ram pressure, cylinder temperature, energy consumption) and provide remote fault warnings (e.g., hydraulic oil leakage, ram deformation). This reduces manual inspection workload, minimizes unplanned downtime, and is well-suited for the needs of unmanned or semi-unmanned recycling factories.

Conclusion: Choosing the Right Hydraulic Metal Baler Equals Grasping the "Efficiency Lever" of the Recycling Industry

For recyclers, the hydraulic metal baler is not an "optional equipment" but a "profit amplifier"——it can solve the three major pain points of "high transportation cost, large warehousing pressure, and downstream bargaining" at one time. Remember three core logics: choose configuration according to waste type, choose model according to site scale, and focus on trends (intelligence, greenization) according to long-term needs. Now, think clearly about the "three questions for selection" according to your own recycling business, and then contact equipment manufacturers, so that you can really buy equipment that "can help you make money". If you still have questions about specific waste or sites, feel free to leave a message in the comment area, and we can further help you disassemble the plan.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment