In the industrial scenario of electronic waste (WEEE) resource utilization, the electronic waste PCB shredder is a core piece of equipment in the printed circuit board (PCB) recycling production line. For electronic waste disposal enterprises, PCB manufacturing industries, and non-ferrous metal recycling practitioners, the selection, operation and maintenance, and production line integration of the equipment directly affect the recycling efficiency and economic benefits. The following sections break down the key details of equipment technology, application, and operation and maintenance starting from industry pain points.

1. PCB Shredder: The Technical Logic to Solve the Dual Pain Points of "Shredding + Sorting"

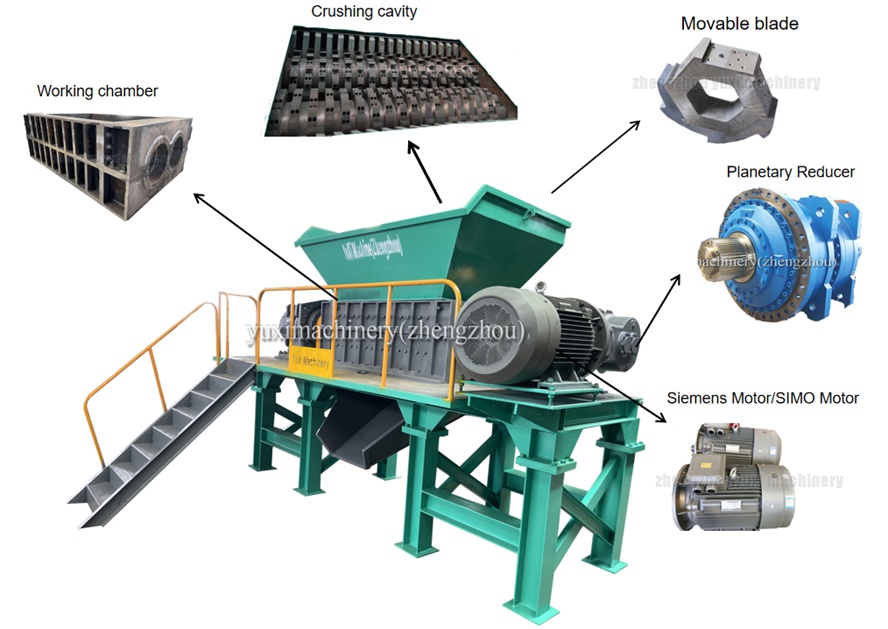

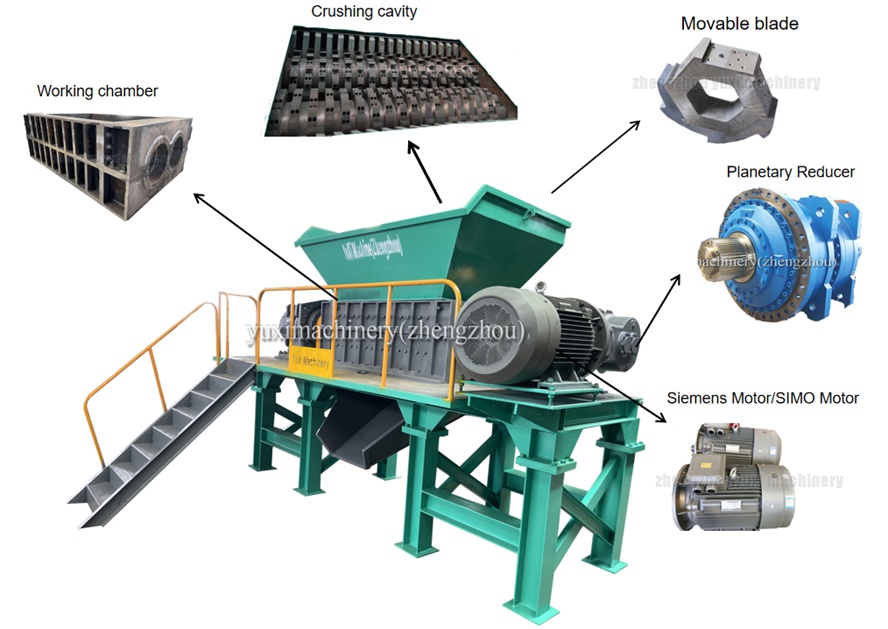

The electronic waste PCB shredder consists of six major modules: shredding blade set, bearing box, box support, feeding system, power system, and electronic control system. It forms a solution of "mechanical shredding + physical sorting" for the industry's pain points of "incomplete PCB shredding and low separation efficiency of metal and non-metal":

• Shredding Module: Adopts a dual-shaft or four-shaft shredding structure. The blade set is forged from Cr12MoV special alloy, and through the combined force of "shearing + extrusion", it shreds PCB boards, electronic components, and other materials to a particle size range of 2-8 inches (meeting the material particle size requirements for subsequent sorting). Taking the dual-shaft model as an example, the two counter-rotating knife shafts drive the blades to interlock, which can efficiently tear the copper foil, resin substrate, and welding components of the PCB board, solving the problems of "difficult shredding of thick boards and easy jamming of thin boards".

• Sorting Coordination: After shredding, the materials need to be connected to equipment such as eddy current separators and gravity separators — using the difference in density and conductivity between metal and non-metal to separate metals such as copper and aluminum from resin powder. For example, the eddy current separator can make conductive metal particles generate induced current through a high-frequency magnetic field, which is deflected by the Lorentz force, completely separating metal and non-metal components.

2. Technical Parameters and Equipment Characteristics (Matching Different Scale Requirements)

(1) Core Parameters: Covering All-Scenario Processing Needs

• Feeding Size: Supports the range of 4-120 inches, suitable for feeding scenarios from a single PCB board to a whole scrapped electrical appliance (such as a computer host, TV case);

• Production Capacity: Ranges from 150-22,000 cubic feet per hour. Small laboratory models (150 cubic feet per hour) meet small-batch scientific research tests, and large industrial production lines (22,000 cubic feet per hour) are suitable for industrial park-level electronic waste disposal;

• Applicable Materials: In addition to PCB boards, it can handle lithium batteries, washing machine/refrigerator casings, metal barrels, color steel tiles, automobile frames, and other wastes with metal-nonmetal composite structures.

(2) Equipment Characteristics: Addressing the Industry's Demands for "Durability, Environmental Protection, and Intelligence"

1. Tool System: Uses "repairable" alloy blades, which improve wear resistance by 3-5 times and support multiple grinding and repair operations, greatly reducing consumable costs (solving the pain point of "easy blade damage and high replacement cost");

2. Structural Strength: The frame is welded as a whole with ASTM A516 Gr70 high-strength steel plate, and with the design of reinforcing ribs, the torsion resistance is improved by 40%, which can withstand the impact load of metal components in the PCB board;

3. Environmental Protection and Energy Efficiency: Equipped with Siemens/SIMO motors + planetary reducers, it realizes "low speed, high torque" operation, with noise controlled below 85dBA, and the dust concentration during shredding is lower than 0.003 ounces per cubic foot (meeting the relevant requirements of European and American clean air regulations);

4. Intelligent Control: The PLC microcomputer system supports precise control of startup, stop, reverse rotation, and overload reverse rotation, and can be directly connected to the production line central control system (meeting the integration requirements of automated production lines).

3. Application Scenarios and Production Line Integration (From Single Equipment to Whole-Line Implementation)

(1) Three Core Application Scenarios

1. Electronic Waste Disposal Center: Conducts centralized shredding of scrapped computers, mobile phones, and home appliances — for example, after disassembling a scrapped laptop, the PCB board and the outer plastic shell are fed into the machine at the same time, and then connected to sorting equipment to recover copper, aluminum, and engineering plastics;

2. PCB Manufacturing Industry: Processes production scraps and defective PCB boards to realize the recycling of copper foil and resin substrate (reducing the cost of raw material proent);

3. Non-Ferrous Metal Recycling Field: Aims at electronic waste containing precious metals (such as waste integrated circuit boards), and after shredding, it is combined with hydrometallurgy or pyrometallurgy to purify gold, silver, palladium, etc.

(2) Complete Production Line Integration Solution

A highly efficient electronic waste PCB shredding and sorting line needs to include the following links (solving the problems of "low single-machine efficiency and incomplete sorting"):

1. Pretreatment: The PCB dismantling machine separates large components (capacitors, chips) and removes dangerous components such as batteries;

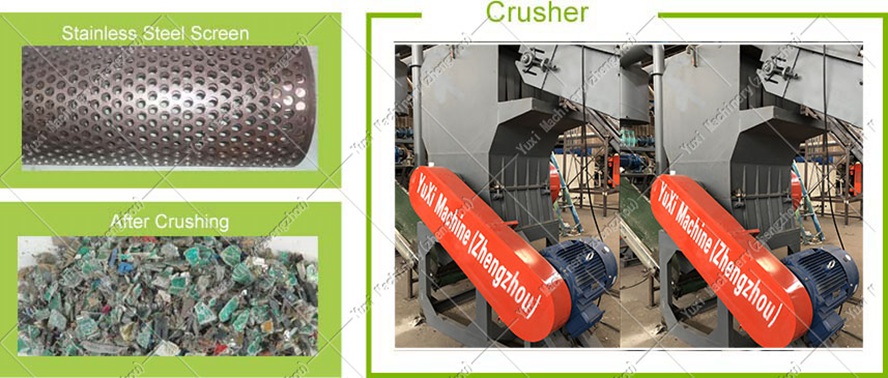

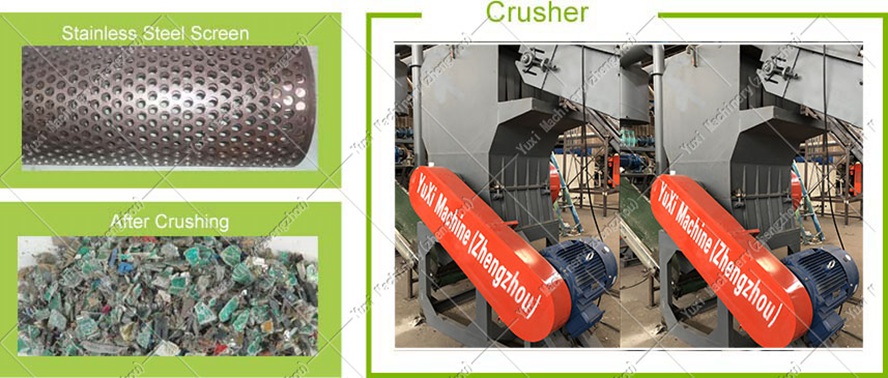

2. Shredding: Coarse shredding by Shredder + fine shredding by Crusher to refine the material particle size to the target range;

3. Dust Removal: The pulse dust collector captures ultra-fine dust (avoiding dust pollution and metal loss);

4. Sorting: The gravity separator separates light and heavy materials, and the electrostatic separator further purifies metal and non-metal;

5. Deep Processing: The plastic rubber grinding equipment granulates and regenerates resin powder, and the rare metal separation equipment extracts precious metals.

4. Operation and Maintenance System: The Key to Making the Equipment "Generate Revenue Stably for a Long Time"

Aiming at the industry's pain points of "difficult equipment operation and maintenance and large loss due to shutdown failures", a hierarchical operation and maintenance mechanism is established:

• Weekly Inspection: Check the tightening status of bolts, the integrity of sensor leads, test run the reducer and motor, and monitor abnormal noise and temperature rise;

• Monthly Inspection: Evaluate the wear degree of wearing parts such as shredding blades and liners, and clean up the residual materials in the feed inlet/shredding cavity;

• Annual Overhaul: Dismantle and clean the motor/reducer, replace seals and lubricating oil, overhaul the shredding roller bearings, and perform program verification and hardware dust removal on the PLC system.

5. Precise Q&A (Solving the 4 Most Concerned Problems of Practitioners)

Q: Can electronic waste with batteries be directly fed into the shredder?

A: No. Direct shredding of dangerous components such as lithium batteries may cause short circuits and combustion. The batteries need to be removed first, and then the remaining materials can be fed into the machine.

Q: How to select equipment for PCB boards of different thicknesses?

A: For thick boards (such as industrial control PCB), select models with dense knife teeth and large torque; for thin boards (consumer electronics PCB), use the conventional shredding structure, but the feeding speed needs to be adjusted to prevent jamming.

Q: How to improve the recovery rate of metal after shredding?

A: Ensure uniform shredding particle size (avoiding excessively fine metal particles), and optimize the wind speed and magnetic field strength in the sorting link (for example, the magnetic field frequency of the eddy current separator needs to match the metal particle size).

The technological iteration of the electronic waste PCB shredder has always focused on "efficient shredding, clean production, and high-value recycling". With the integration of intelligent technologies, the resource recycling efficiency and operation and maintenance convenience of the equipment will be further improved, becoming a core productivity tool in the electronic waste resource utilization track.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment