For those in the scrap metal recycling industry, a scrap metal shredder is not just a production device, but a core asset that determines recycling efficiency and profit margins. This content breaks down the key points throughout the equipment's lifecycle, from technical details to commercial implementation.

I. Core Equipment Parameters: Match Your Needs to Avoid Mistakes

(I) Industrial-Grade Models (for Medium-to-Large-Scale Recycling Scenarios)

• Processing Capacity: The feed size ranges from 4 to 118 inches, with a processing capacity of 0.44 to 66 short tons per hour, meeting large-scale needs such as end-of-life vehicle dismantling and metallurgical solid waste treatment.

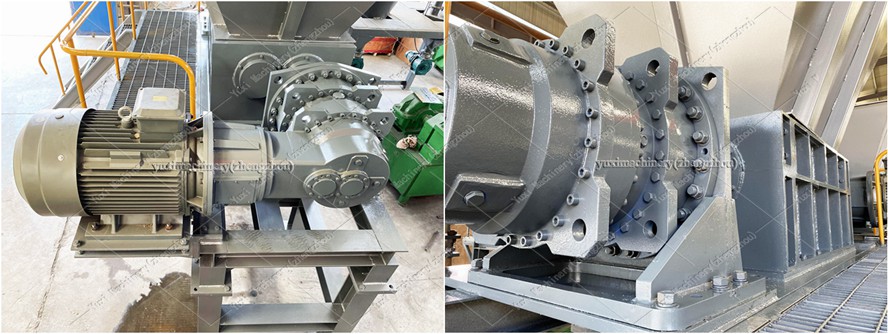

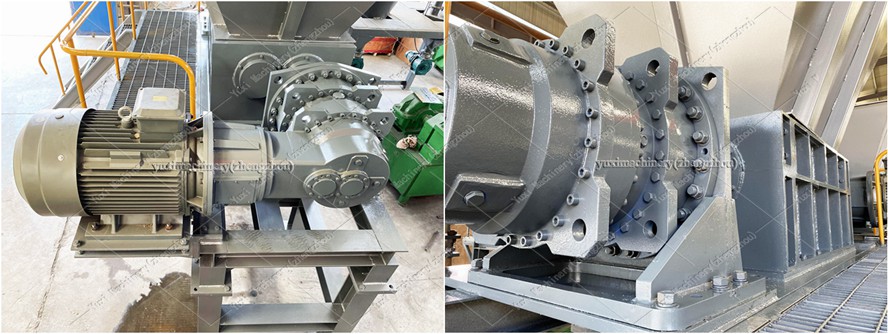

• Technical Configuration: Equipped with a dual-shaft independent drive system and spiral-arranged alloy steel cutters, it improves production efficiency by over 30% compared to traditional equipment when handling high-toughness, high-hardness materials (e.g., used rail tracks). The bearings adopt a six-layer sealing design for dust and water resistance, extending their service life by at least 50%.

(II) mini metal shredder (for Micro-Small Recycling Startups)

• Space and Performance: With a machine weight of ≤ 660 pounds, it can be installed in just 10 square feet of space. The shredding chamber volume is 5 to 20 liters, and when processing small materials like used screws and aluminum cans, the particle size can be adjusted to 0.39 to 3.15 inches, meeting small-batch, high-frequency needs.

• Cost Advantages: Compatible with 120V civilian power supply (2.2-5.6kW), the equipment investment can be recovered through recycling price differences within 1-2 years. Customizable feed inlets are available to optimize shredding efficiency for specific materials (e.g., aluminum cans).

II. Three Principles for Selection: Precise Matching of Materials, Site, and Cost

Principle 1: Material Characteristics Determine Equipment Configuration

• High-Hardness Materials (thick steel plates, used rail tracks): Prioritize models with high-chromium alloy cutters, which offer 3 times better wear resistance and reduce cutter replacement costs.

• Soft Metals (copper, aluminum): Choose models that support speed/cutter gap adjustment to avoid material adhesion and jamming, reducing time wasted on material cleaning.

Principle 2: Site Scale Defines Equipment Specifications

• Micro-Small Sites (daily recycling ≤ 2 tons): mini metal shredders are the optimal choice, with a lightweight design that requires no dedicated workshop and can be powered by a 120V circuit.

• Large-Scale Sites (daily recycling ≥ 50 tons): Industrial-grade models with intelligent monitoring modules to real-time track load and prevent production halts due to overload.

Principle 3: Maintenance Costs Affect Long-Term Profitability

• Service Life of Wear Parts: Prioritize models with "repairable cutters + sealed bearings" to reduce annual replacement costs of core components by 40%.

• After-Sales Response: Select manufacturers that provide nearby warehousing and on-site maintenance to improve the response speed of parts and services by 50% in case of equipment failure.

III. Mini metal shredders: "Light-Asset Gold-Mining Tool" for Micro-Small Startups

Tailored for startups with limited funds and experience, miniature models are fully designed to meet the needs of "low-threshold entry":

• Extremely Easy Operation: The PLC automatic control system supports one-click start/stop and overload reversal, allowing users without technical experience to master operation quickly.

• Flexible Sales Support: Manufacturers offer "online model selection + on-site testing" services. The feed inlet and cutter parameters can be customized according to recycled materials (e.g., aluminum cans, thin iron sheets), enabling immediate production upon delivery.

• Clear Profitability: Based on average scrap metal recycling prices, a miniature shredder with a processing capacity of 1.1 short tons per hour can recover equipment costs in approximately 1 year, with sustained pure profit margins afterward.

IV. Profit Enhancement: "Invisible Benefits" Brought by Shredders

• Material Value Upgrade: The increased surface area of shredded scrap metal (e.g., shredded steel improves smelting efficiency by 15%-20%) generates an additional income of over $20 per ton.

• Transport Cost Reduction: The density of shredded materials increases, doubling the transport volume under the same capacity and cutting transportation costs by 50%.

• Environmental Compliance Premium: Equipment meeting standards such as EPA/OSHA qualifies for recycling subsidies while avoiding environmental fines, indirectly enhancing profit stability.

V. Maintenance and Quick Solutions to Common Problems

Cost-Saving Maintenance Actions

• Regular Inspections: Inspect the wear of cutters and bearings every 72 hours, and replace wear parts in advance to avoid unplanned production halts due to sudden failures.

• Cleaning Habits: Clean residual materials in the shredding chamber daily, especially after processing oil-based/painted materials, to prevent corrosion of the equipment inner wall.

VI. Answers to Frequently Asked Questions

1. How to handle equipment jamming?

Immediately activate the reverse function to remove the material. If jamming persists, disassemble the machine for manual cleaning, then adjust the feed size to avoid over-specification feeding.

2. How to comply with noise and dust regulations?

Equip miniature models with sound insulation cotton and external dust collection equipment; for industrial models, use bag-type dust collection systems to meet local environmental noise and dust limits.

3. What is the investment payback period?

Small models (1.1-2.2 short tons per hour) take approximately 1-2 years, while large industrial models (over 11 short tons per hour) take 2-3 years. The specific period is affected by local scrap metal price fluctuations.

The selection and operation of a scrap metal shredder essentially involve a balance between "efficiency and cost" in the scrap metal recycling business. Industrial-grade models support enterprise-level recycling chains with large-scale capacity, while miniature models open up low-threshold entry channels for micro-small startups. Regardless of scale, focusing on the three cores—"matching parameters to needs, reducing losses through maintenance, and enhancing value through shredding"—will turn the equipment from a "production tool" into a "profit lever," enabling sustained gains in both commercial and environmental benefits in the resource recycling sector.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment