In the industrial implementation phase of metal resource recycling, the pretreatment of waste metal containers (aluminum cans, iron cans, etc.) has always been an efficiency bottleneck—pain points such as large volume, high transportation cost, and difficult processing all need a professional can shredder to break through. The following deeply analyzes this core equipment from the dimensions of core technology, parameter adaptation, and process synergy, accurately matching the actual needs of recycling enterprises and resource-based factories.

1. First, understand: What problems does a can shredder solve?

For metal recycling practitioners, there are three major pain points in scattered materials such as aluminum cans and iron barrels:

• "Difficult transportation": Hollow containers take up space, and the tonnage transportation cost is more than 30% higher than that after crushing;

• "Difficult processing": Complete containers entering the subsequent production lines (such as smelting and sorting) will sharply increase equipment load;

• "Difficult recycling": Special-shaped materials such as old appliance casings and thick-walled iron barrels are prone to jamming in traditional crushers.

The core value of a can shredder is to tear and cut these materials into regular pieces of 30-80mm through the "twin-shaft shear crushing technology"—which is equivalent to "paving the way" for metal recycling, increasing the efficiency of subsequent processes by more than 40%.

2. Core structure: Why can professional models be stable and efficient?

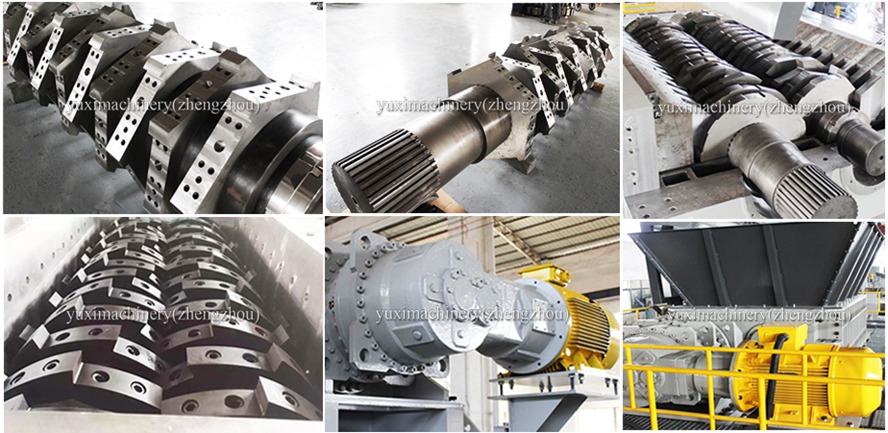

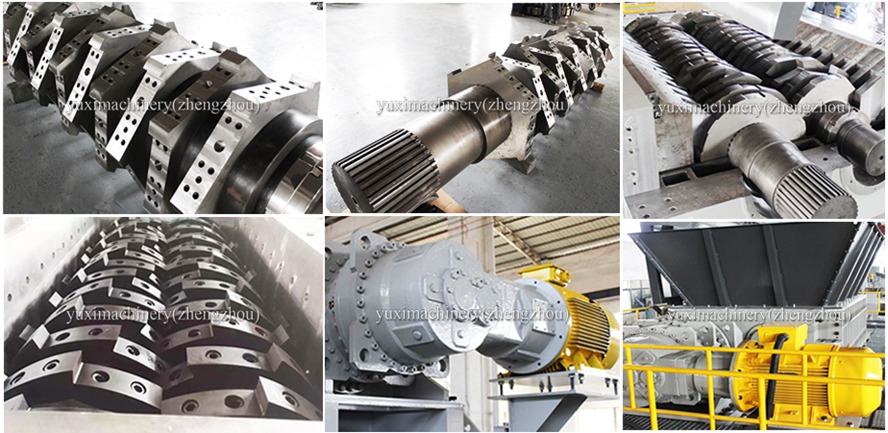

1. Crushing system: The key design to "chew and tear evenly"

• Cutters and shafts: High-carbon steel alloy cutters are used, and the thickness can be customized according to materials (15mm grade for aluminum cans, 30mm grade for thick iron barrels). With the design of "spiral arrangement + hexagonal inner hole", the force is more uniform. The twin shafts have a speed difference of 1:1.2 to ensure the continuous crushing process of "grabbing-cutting-discharging" materials;

• Crushing chamber: The inner wall is lined with wear-resistant manganese steel liners with a thickness of 20-40mm, which has excellent impact and wear resistance and can withstand high-frequency impacts from metal cans; "Anti-winding ribs" are set in the chamber to prevent materials (such as cans with residual liquid) from winding around the shafts.

2. Drive and protection: Industrial-grade configuration for "durability and quietness"

• The power end uses a variable-frequency speed-regulating motor + hard-toothed surface reducer, and the power covers the range from 20HP to 340HP (corresponding to small to large models), and can automatically adjust the speed according to the load, reducing the probability of jamming and overload shutdown by 90%;

• The bearing has a six-layer seal (waterproof and dustproof), and the outer shell is attached with sound insulation cotton + dust cover, and the noise is suppressed below 85dB (measured 1m away from the equipment), so there is no need to worry about environmental protection inspections.

3. Parameter selection: Accurately match your production line scale

Directly use the industrial-grade selection table (typical parameters of the YXS series) so you no longer have to "guess the size" when choosing a model:

| Model | Power (HP) | Processing Capacity per Hour (tons) | Applicable Material Size (inches) | Hopper Size (feet) | Equipment Weight (tons) | Overall Dimensions (length×width×height, feet) |

| YXS-600 | 20 | 2-3 | 1.18-3.94 | 2.69×2.95 | 2.5 | 8.53×6.56×6.23 |

| YXS-1000 | 50 | 5-8 | 1.18-3.94 | 3.94×3.28 | 5.7 | 9.84×6.56×6.23 |

| YXS-1600 | 100 | 12-18 | 1.18-3.94 | 7.55×6.56 | 24 | 16.4×9.84×7.87 |

| YXS-2600 | 215 | 25-60 | 1.18-3.94 | 10.5×6.56 | 85 | 26.9×13.1×14.1 |

• Small recycling stations choose YXS-600: It handles scattered aluminum cans and other light materials, covers only 53 square feet, and is flexible to move;

• Large-scale recycling plants choose YXS-2600: It can shred thick-walled iron barrels and old appliance casings (such as refrigerator and washing machine casings) and other heavy materials, with an hourly processing capacity of 60 tons, maximizing production line efficiency.

4. Process synergy: Cooperate with an aluminum can crusher to earn 20% more from aluminum recycling

For those engaged in high-value aluminum can recycling, note that the can shredder and aluminum can crusher are a "golden combination":

1. First step (rough crushing): The can shredder tears complete aluminum cans into pieces of 1.18-3.15 inches, breaking the "barrel body-can lid" structure of aluminum cans, releasing internal space and reducing volume;

2. Second step (fine grinding): The aluminum can crusher then grinds the roughly crushed materials into aluminum powder/granules of 0.04-0.2 inches, and separates impurities such as plastic films and printing coatings at the same time, finally obtaining aluminum raw materials with a purity of >95%.

With this process, the aluminum resource recovery rate can be 20%-30% higher than that of using only a crusher, and smelting energy consumption can also be reduced by 15%.

5. Maintenance + Pit avoidance: Tips to make the equipment last 3 more years

1. Daily inspection (must-do items)

• Check the tightness of the shaft bolts every 8 hours, and keep the torque at 295-434N·m;

• Monitor the main motor current every week, and check the load if the fluctuation exceeds 10%;

• Measure the cutter wear every month. If the wear depth exceeds 0.197 inches, use tungsten carbide spraying for repair immediately (one repair can be reused 3-5 times).

2. Pit avoidance reminders

• Don’t buy "single-shaft models" for cheap: Twin-shaft shearing is the core technology for shredding metal cans, and single-shaft models are prone to jamming and uneven shredding;

• Don’t mix materials too randomly: For example, mixing car casings and thin aluminum cans for shredding will double the cutter wear rate (if you really need to mix, customize thicker cutters with the manufacturer in advance).

6. High-frequency Q&A (directly solving your most concerned issues)

1. Can I put cans with residual liquid into it?

Yes! There is a liquid discharge port at the bottom of the crushing chamber, and the inclined discharge design will drain the liquid completely. The sealing system is also waterproof, so the bearing will not be damaged by soaking.

2. I’m a small workshop, which model is cost-effective?

First calculate the "daily processing capacity + material type": If you only process a few tons of scattered aluminum cans every day, YXS-600 is sufficient; if you want to take over factory waste orders, choose YXS-1000 directly, which can handle future production expansion.

3. What’s the difference between an aluminum can crusher and this machine?

Simply put: The can shredder is for "shredding large pieces into small ones" (rough crushing), while the aluminum can crusher is for "grinding small materials into fine ones + sorting impurities" (fine processing). Using the two machines together can maximize the profit from aluminum recycling.

As a core equipment for metal recycling pretreatment, the can shredder accurately solves the industry pain points of "difficult transportation, difficult processing, and difficult recycling" of waste metal containers with its professional twin-shaft shear crushing design, flexible parameter adaptability, and process synergy with aluminum can crushers. Following the logic of "material matching + production line scale + long-term cost" from selection to maintenance, it can help practitioners greatly improve recycling efficiency and reduce comprehensive costs, and is an irreplaceable key equipment in the metal resource utilization industry chain.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment