In the wave of global circular economy and compliant industrial solid waste disposal, the scrap metal shredder has become a core solution for scrap metal recyclers to break through the three pain points of "low disassembly efficiency, high transportation costs, and environmental risks". This article starts from the real needs of practitioners, disassembles equipment technical details, application scenarios, and the precise value of mini models to help you choose the right equipment and reduce costs and increase efficiency.

1. Technical Disassembly: How Does Dual-Shaft Shredding Solve "Difficulties in Metal Recycling"?

(1) Core Principle: From "Violent Disassembly" to "Precision Crushing"

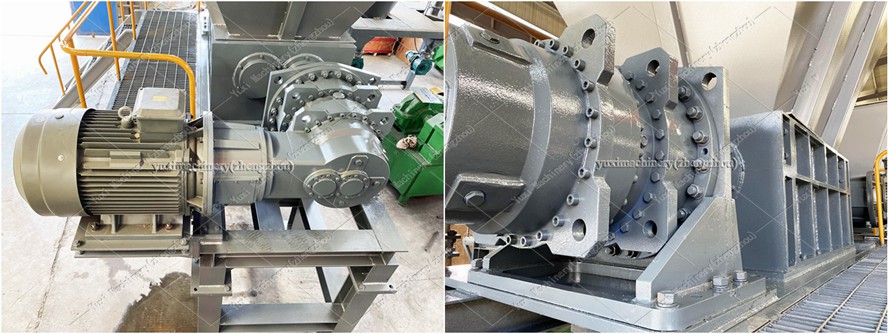

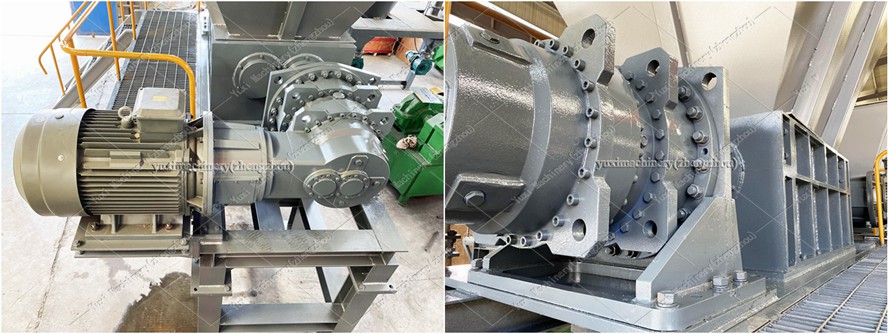

Mainstream scrap metal shredders adopt a dual-shaft independent drive structure. Through the "low-speed and high-torque" rotation of the cutter shafts, they realize the composite crushing of metal materials through extrusion + shearing + tearing. The cutter shaft blades are made of AISI H13/A2 tool steel (strengthened by heat treatment), which has both high wear resistance and impact resistance. The blades are arranged in a helical pattern and cooperate with a hexagonal inner hole spindle design, so that the force is uniform and the cutting efficiency is increased by 30%.

Take the industrial-grade YXS-2600 model as an example. The PLC intelligent control system can automatically identify "material jamming" and trigger reverse rotation, completely eliminating the risk of equipment shutdown and ensuring production continuity.

(2) Model Classification: Precise Matching from "Large-Scale" to "Small-Batch"

| Model Type | Representative Model | Production Capacity | Power Configuration | Core Adaptation Scenarios |

| Large Industrial | YXS-2600 | 25-60 tons/hour | 215×2 HP | Regional scrap metal recycling industrial park |

| Mini Operational | YXS-600 | 2-3 tons/hour | 20×2 HP | Small recycling workshops, laboratory trial production |

2. Scene Penetration: Is Your Waste Really "Disassembled Correctly"?

The value of the scrap metal shredder lies in making every type of waste "monetize more efficiently":

• Vehicle Parts Recycling: Waste tires, engine casings, forklift pallets with a thickness of ≤10mm, etc. After crushing, the metal purity increases by 20%, and the purchase price of smelters rises directly.

• Hazardous Waste Barrel Treatment: "Environmentally sensitive" wastes such as paint barrels and diesel barrels can enter the incineration/recycling process compliantly after crushing, avoiding environmental fines of tens of thousands of dollars.

• Centralized Processing of Light and Thin Materials: Aluminum cans, waste aluminum sheets, scrap steel, etc. After crushing, the bulk density increases by 40%, and the transportation cost per ton drops by 300 US dollars directly.

For practitioners with "daily processing capacity < 20 tons", the mini scrap metal shredder is a precise choice for reducing costs and increasing efficiency:

• Full Model Coverage: YXS-600 to YXS-1000 series, with a production capacity of 2-8 tons/hour, power options of 20×2-50×2 HP, and a minimum floor area of only 2.6×2×1.9 meters, which can be easily arranged in small factories.

• Customized Solution: It supports the selection of special cutters according to materials (such as high-toughness copper materials and high-hardness alloy steel), or adjusts the feed port size to adapt to "non-standard waste", completely solving the problem of "material mismatch and equipment idling".

• Zero Pressure in Operation and Maintenance: Free "installation guidance + 1-year warranty + lifetime technical support" is provided, tool consumables are available in stock, and the later maintenance cost is 25% lower than that of similar equipment.

4. Must-See for Practitioners: 3 "Decision Blind Spots" Avoidance Guidelines

1. Q: Can High-Hardness Alloys Be Shredded?

A: Most scrap metals can be processed, but super-hard alloys with hardness > HRC60 need to be communicated in advance – we will match you with a "customized cutter solution" to avoid excessive equipment wear.

2. Q: How to Choose Between Mini and Large Machines?

A: Judge by "daily processing capacity": If the daily processing is < 20 tons, choose a mini machine (such as YXS-1000), and the unit ton processing cost is 15% lower than that of a large machine; if the daily processing is ≥ 30 tons, the scale effect of large machines (such as YXS-2000) is more prominent. A free "capacity-cost calculation model" can be obtained.

3. Q: What Are the Hard Requirements for Site Installation?

A: The ground bearing capacity needs to reach 1.5 times the weight of the equipment (for example, YXS-600 needs ≥ 3.75 tons/㎡), and 480V industrial power is required. There are no additional restrictions as long as the ventilation conditions meet the standards.

The "profit code" of scrap metal recycling is hidden in every detail of "crushing efficiency, transportation cost, and environmental compliance". Whether you are a novice who wants to enter the industry or an old player who wants to upgrade equipment, the full-matrix products from industrial-grade to mini-type can precisely match your needs. Click the "Consultation Entry" at the end of the article to directly obtain a customized equipment plan + latest quotation and make your recycling business "profitable as soon as it is shredded".

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment