Driven by resource circulation and environmental policies, the scrap metal shredder has become a core equipment for cost reduction, efficiency improvement, and resource regeneration in the metal recycling industry chain. This article dissects the professional details of scrap metal shredders from the dimensions of technical principles, parameter adaptation, scenario application, and equipment selection, while also analyzing the sales value of miniaturized equipment, helping readers accurately solve equipment selection and operation problems.

1. Core Working Principle: The Industrial Logic of Dual-Shaft Shredding Technology

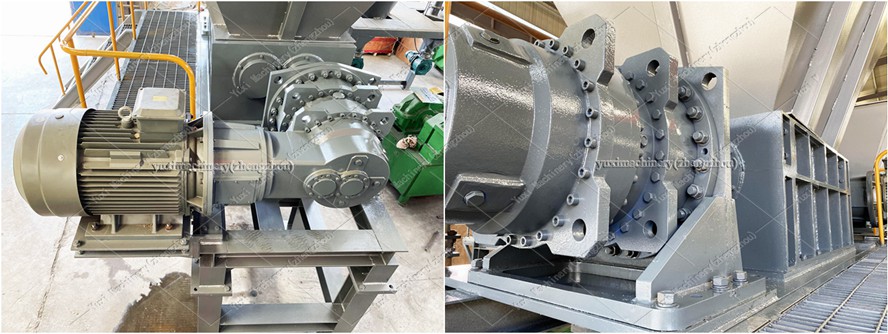

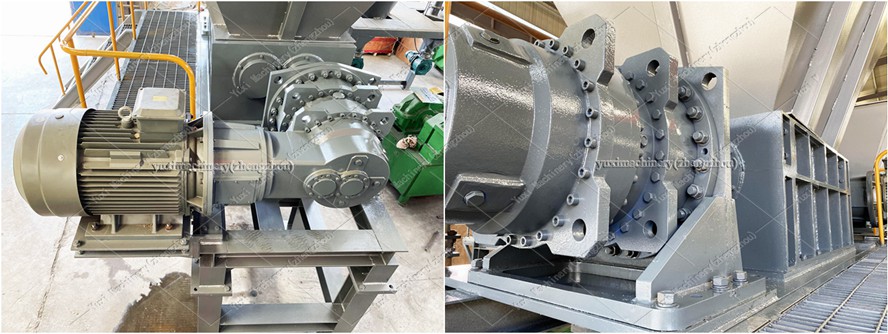

The scrap metal shredder adopts a dual-shaft independent drive + low-speed and high-torque design, realizing extrusion, shearing, and tearing of scrap metal through the coordinated operation of the cutter shaft and special cutters.

• Cutter System: Made of ASTM A6 tool steel through heat treatment process, the helically arranged cutters, combined with the hexagonal inner hole/spindle surface design, ensure uniform force, high cutting efficiency, and excellent wear resistance.

• Sealing and Transmission: The bearing is equipped with an IP68-grade sealing structure, which is waterproof and dustproof while prolonging the service life; the motor-reducer drive system achieves a "low-speed and high-torque" shearing effect to avoid material jamming.

• Intelligent Control: Equipped with a UL 508A standard PLC control system, supporting start, stop, reverse, and overload automatic reverse functions, and the whole process of automatic control reduces manual dependence.

2. Technical Parameters: Key Indicators for Accurate Matching of Recycling Scenarios

The parameter differences of different types of equipment directly affect scenario adaptability, and core parameters need to be focused on:

| Equipment Type | Feed Size Range | Production Capacity Range | Typical Application Scenarios |

| Small Shredder | 4 - 48 inches | 880 - 22,000 lbs/h | Small recycling points, laboratory shredding |

| Large 2600 Model | 12 - 118 inches | 55 - 132 tons/hour | Industrial metal recycling and processing centers |

Applicable materials cover "high-toughness thin metals" such as metal barrels, color steel tiles, car shells, and waste aluminum skins, and can even handle complex components such as waste forklift pallets and engine shells with a thickness ≤ 10mm.

3. Industry Value: Multidimensional Breakthrough from Environmental Compliance to Profit Enhancement

Under the framework of European and American EPA resource recycling regulations and ISO 14001 environmental standards, the value of scrap metal shredders is reflected in:

1. Resource Volume Reduction and Transportation Optimization: The bulk density of metal increases by more than 30% after shredding, significantly reducing logistics and warehousing costs.

2. Smelting Efficiency Improvement: The shredded metal materials have a larger surface area, resulting in more sufficient reaction during smelting and a 15%-20% reduction in energy consumption.

3. Environmental Risk Avoidance: The closed shredding process eliminates dust leakage, and the noise is controlled below 85dB, fully complying with the OSHA occupational health standards.

4. Mini Scrap Metal Shredder: A "Game-Changing Choice" for Small-Scale Recycling Scenarios

For the needs of small recycling enterprises and workshops, the differentiated advantages of mini scrap metal shredders are significant:

• Operational Convenience: With a split-box design, the cutter shaft (including cutters, bearings, and seals) can be disassembled and replaced within 5 minutes.

• Cost Flexibility: Modular configuration according to "cutter material, motor power, and control system" is supported, and the price is elastically adjusted according to demand.

• Technical Support: Provide ASTM standard process guidance, including full-process services such as cutter repair (AWS D1.1 welding process) and equipment commissioning.

5. "Pit-Avoidance Guide" for Selection and Operation

(1) Three Questions for Equipment Selection

1. "What is the maximum size of my material?" —— The feed size determines the core indicator of the equipment model.

2. "What is the daily processing capacity required?" —— Production capacity is directly related to equipment configuration and input costs.

3. "What is the later operation and maintenance manpower and budget?" —— Large equipment requires a professional team for maintenance, while miniaturized models can be "operated by one person + simple maintenance".

(2) Tips for Extending Cutter Life

• For "high-hardness metals" (such as waste steel), use high-speed steel cutters and perform edge grinding every 500 hours of operation.

• When processing "thin and tough metals" (such as cans), use tool steel spiral cutters to avoid excessive wear.

The scrap metal shredder is not just a simple "shredding tool", but a core asset for the resource recycling industry to move from "compliant survival" to "profitable development". Whether it is a large-capacity industrial equipment or a flexible and compact mini model, choosing the right equipment can establish dual advantages in efficiency and cost in the metal recycling track. For a customized selection plan or the latest quotation for mini equipment, you can leave a message directly through the official website, and the technical team will provide a precise reply within 24 hours.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment