In the fields of waste cable recycling, electronic waste disposal, and resource recycling, the cable shredder is a key device for efficiently dissociating and accurately sorting metals (such as copper and aluminum) and insulating materials (such as PVC and rubber). Through an integrated process of "mechanical shredding + physical sorting", it converts mixed waste cables into high-purity recyclable materials, and is a core tool for developing "urban mines" in modern circular economy.

1. Core Principles and Structural Composition of Cable Shredders

The working process of cable shredders is based on a "multi-stage shredding + multi-process sorting" collaborative mechanism, enabling efficient processing of waste cables of different types and specifications.

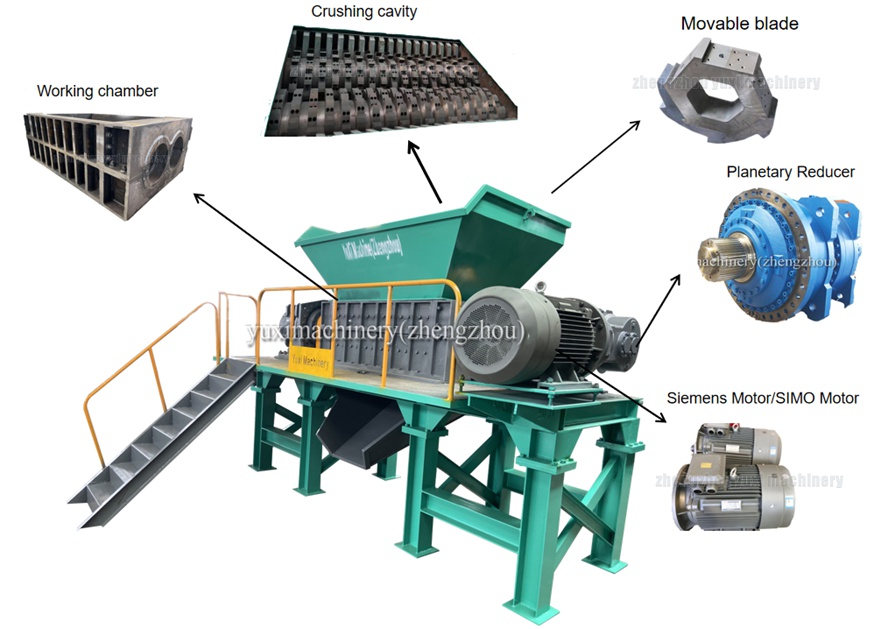

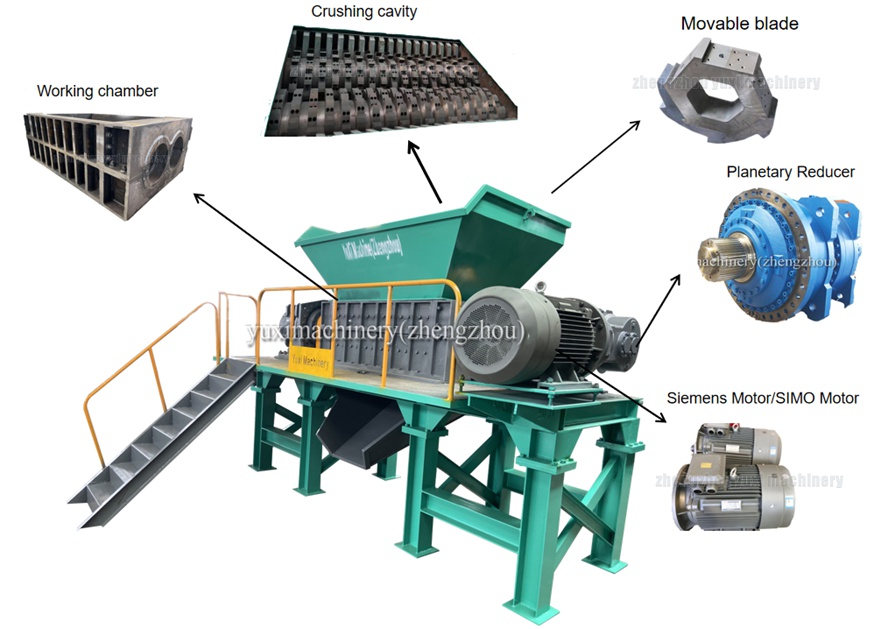

1.1 Shredding System: A Composite Structure of Dual-Shaft Shredding + Hammer Crushing

• Dual-shaft shredding mechanism: Uses interlaced cutter discs made of alloy steel (AISI D2), and cuts entire or bundled cables into small segments of 50-100mm through the relative rotation of two shafts (rotating speed is about 20-50r/min). The cutter discs are designed with a self-cleaning tooth structure to prevent PVC and rubber sheaths from winding and ensure continuous shredding.

• Hammer crushing unit: Composed of a high-speed rotating hammer group (rotating speed 1200-1800r/min) and wear-resistant liners, it further crushes the shredded cable segments into particles of 5-15mm, completely dissociating metal conductors from insulating sheaths. The hammers are manufactured using hard alloy surfacing technology, which increases wear resistance by more than 30% and can handle hard conductors such as copper and aluminum cores.

1.2 Sorting System: A Precise Combination of Air Separation + Eddy Current Separation

• Air separation module: Utilizes the density difference between metals and plastics (for example, the density of copper is 8.96g/cm³, and that of PVC is 1.35g/cm³), and separates light plastics from heavy metals through an adjustable air separation box (wind speed is controlled at 18-30m/s). The air separation box is equipped with deflectors and dust removal interfaces, which not only ensure sorting accuracy but also can be connected to a dust removal system.

• Eddy current separation device: Based on the principle of electromagnetic induction, it generates eddy current repulsion on conductive metals (copper, aluminum) to achieve secondary sorting of metals and non-metals. The equipment is equipped with a frequency converter, which can adjust the magnetic field strength according to the particle size and metal content of the materials, and the metal sorting purity can reach more than 99.5%.

1.3 Auxiliary System: Intelligent Control and Environmental Protection Supporting Facilities

• Intelligent temperature control and overload protection: Real-time monitoring of bearing temperature (threshold ≤75℃) through infrared temperature sensors. If there is material blockage or motor overload (current exceeds 15% of the rated value), the system will automatically shut down and trigger an alarm to avoid equipment damage.

• Dust removal system: Equipped with a pulse bag filter (filtration accuracy 5μm) as standard. With the negative pressure design of the shredding chamber, the dust emission concentration is ≤10mg/m³, fully complying with the EPA 40CFR Part 60 standard.

2. Technical Parameters and Application Scenarios of Cable Shredders

Different models of cable shredders vary significantly in processing capacity, feed port size, and sorting accuracy, so precise selection is required according to actual needs:

| Model | Feed Port Size (in) | Processing Capacity (t/h) | Total Motor Power (HP) | Metal Sorting Purity | Applicable Cable Types |

| CF - 600 | 23.6×19.7 | 2 - 3 | 60 | ≥98% | Household waste wires, communication cables |

| CF - 1000 | 39.4×31.5 | 4 - 6 | 100 | ≥99% | Automobile circuit wires, medium-voltage power cables |

| CF - 1500 | 59.1×39.4 | 8 - 10 | 150 | ≥99.5% | Engineering waste cables, bundled industrial cables |

Application scenarios cover the entire industrial chain:

• Waste recycling industry: Conduct centralized shredding and sorting of mixed cables (such as household waste wires and obsolete communication cables) in recycling stations to quickly realize the recycling and monetization of copper and aluminum metals.

• Electronic waste disposal: As a key device in the electronic waste dismantling line, it processes small cables such as computer power cords and mobile phone charging cables to extract precious metals from "urban mines".

• Power engineering field: Process old cables (such as high-voltage cables that have been in service for more than 15 years) to solve the storage problem of waste cables and recover high-value metal resources at the same time.

3. Key Points for Selection and Operation and Maintenance of Cable Shredders

3.1 Core Indicators for Selection

• Adaptability of the shredding chamber: Pay attention to whether it supports direct feeding of multi-specification cables (without disassembling the sheath in advance), and whether the cutter disc has a quick-change module (convenient for switching cutters when processing cables of different materials).

• Intelligence of the sorting system: Give priority to equipment equipped with a PLC touch screen control system, which can adjust parameters such as wind separation speed and eddy current magnetic field strength in real time to meet the sorting needs of different conductors such as copper cores and aluminum cores.

• Energy consumption and efficiency ratio: The unit processing energy consumption of high-quality cable shredders should be ≤12kW·h/t, and the metal recovery rate should be ≥98% to ensure the economy of long-term operation.

3.2 Key Points for Operation and Maintenance

• Maintenance of cutters and hammers: Check the wear of the cutter discs every 400 hours of operation (regrinding is required when the wear amount exceeds 3mm); the hammers are installed symmetrically and can be flipped for use after wear to extend their service life.

• Cleaning of the sorting system: Clean the dust in the air separation box and the impurities on the magnetic roller of the eddy current separator every week; calibrate the magnetic field strength of the eddy current separation every month to ensure stable sorting accuracy.

• Equipment operation ledger: Record data such as each startup time, processing volume, and fault type, and predict equipment failures in advance through current and temperature curve analysis (for example, a continuous high motor current may be a precursor to bearing wear).

4. Frequently Asked Questions (Q&A)

1. Can cable shredders handle high-voltage cables with metal armor?

Yes. For high-voltage cables with metal armor, it is necessary to choose a model equipped with a "shredding + crushing + secondary shredding" three-stage shredding structure. First, the dual-shaft shredder cuts the armor, and then hammer crushing and eddy current separation are used to separate metals and insulating materials.

2. How to reuse the plastic particles after processing?

The separated PVC and rubber particles can be used to produce plastic pipes, rubber products, etc. through granulation process; if it is cross-linked polyethylene (XLPE) insulating material, chemical raw materials can be recovered through cracking process to achieve full resource recycling.

3. What are the site requirements for equipment installation?

A hardened ground (bearing capacity ≥8t/m²) is required, and a maintenance space of at least 2m should be reserved; if a dust removal system is configured, it is necessary to plan the direction of the dust removal pipeline and the noise reduction measures of the fan to ensure that the production environment meets environmental protection and safety specifications.

4. Is customization of special-specification cable shredders supported?

Yes. According to the customer's cable type (such as extra-thick high-voltage cables, multi-core communication cables) and processing volume requirements, customization of feed port size, number of shredding stages, and sorting module configuration is supported, and the customization cycle is usually 6-8 weeks.

As a core equipment for waste cable resource utilization, the technical advancement of cable shredders directly determines the efficiency and value of resource recycling. Choosing a suitable equipment can not only realize the "harmless + resourceful" treatment of waste cables in the environmental protection field but also help enterprises build core competitiveness in the circular economy industry chain.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment