In the field of waste cable recycling and resource utilization, the cable shredder (double-shaft copper wire shredder) serves as a key device. With its efficient shredding of various cables and precise separation of metals and non-metals, it has become a core tool in the circular economy industry chain. This article will professionally and in-depth analyze the details and value of the cable shredder from the dimensions of equipment principle, core structure, technical parameters, application scenarios, and selection points.

1. Working Principle and Core Structure of Cable Shredder

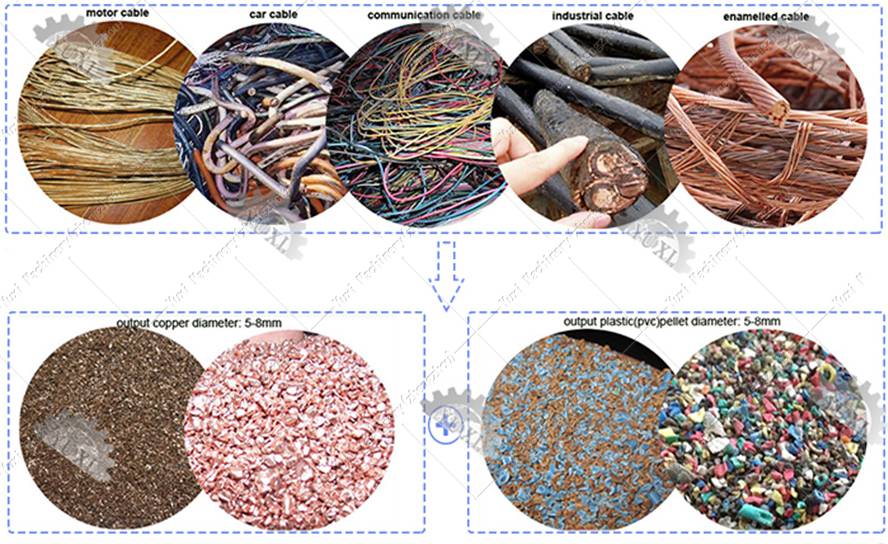

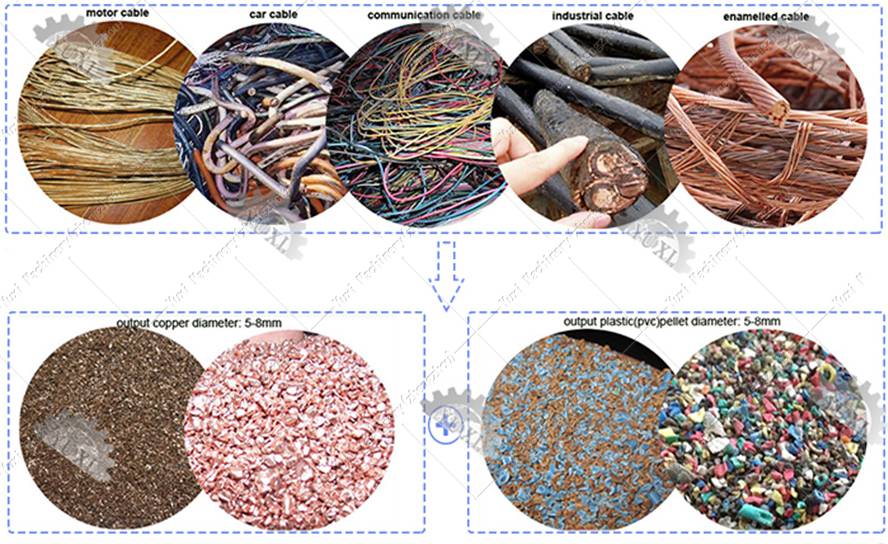

A cable is composed of metal conductors (copper, aluminum, etc.) and insulation sheaths (PVC, rubber, cross-linked polyethylene, nylon, etc.). The cable shredder realizes the efficient dissociation and recovery of metals and non-metals through the process of "mechanical shredding + multi-stage separation".

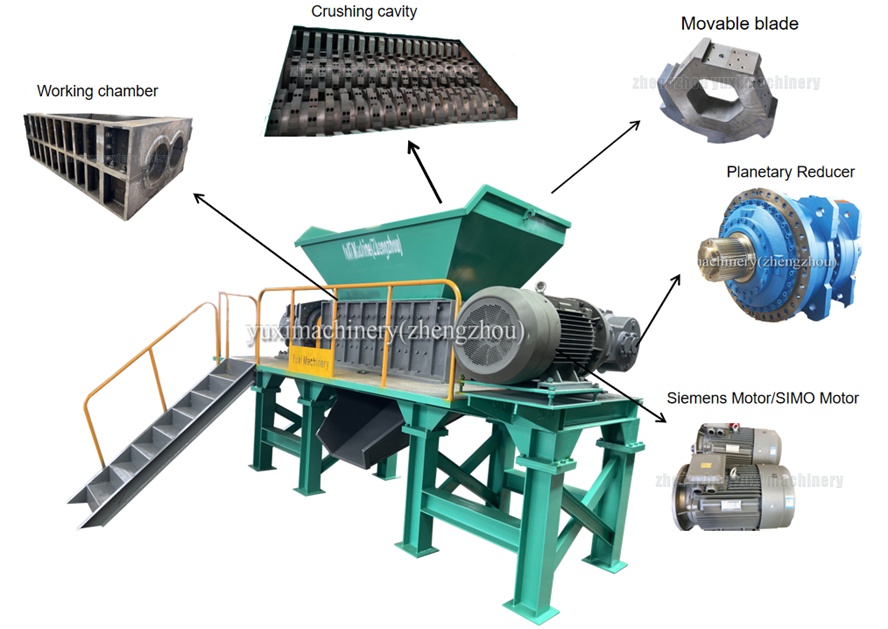

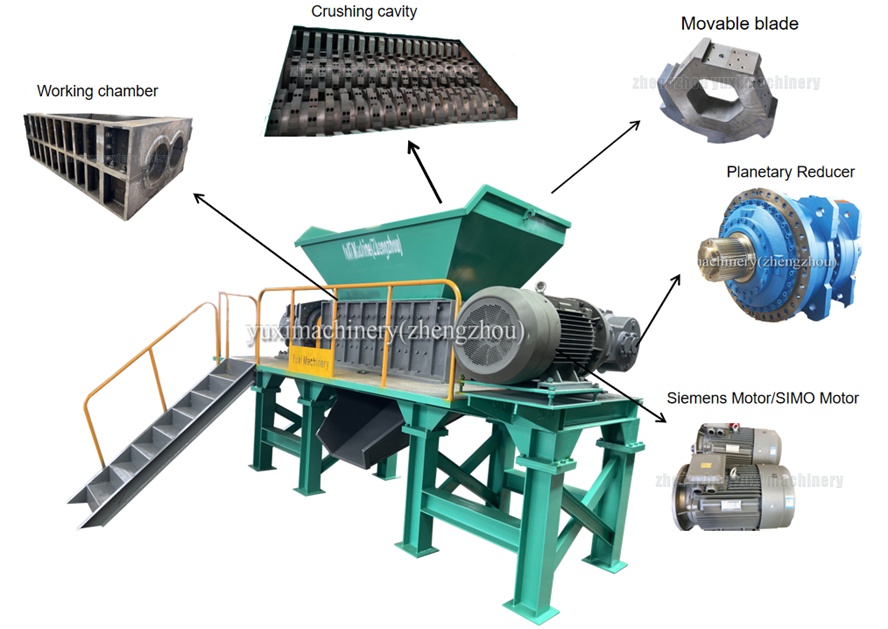

1. Shredding System

• Double-shaft Cutter Roller and Movable Cutter: The movable cutter is forged from AISI H13 alloy steel, and its hardness reaches HRC58-62 after quenching, with excellent wear resistance. The movable cutters are arranged in a spiral and staggered manner on the double-shaft cutter roller. Through the combined action of "shearing + tearing", the cable is forcibly crushed into mixed particles of 5-8mm. The speed of the cutter roller and the number of movable cutters can be customized according to the diameter of the cable (such as thin USB cables to thick industrial cables) to ensure the shredding effect on cables of different specifications.

• Working Chamber and Fixed Cutter: The working chamber is a welded structure made of ASTM A36 high-strength steel plate, with a built-in fixed cutter that cooperates with the movable cutter to form a "movable-fixed cutter shearing group", further enhancing the shredding efficiency. Some models are equipped with a hydraulically driven working chamber cover opening device, which facilitates the maintenance of the cutters and the cleaning of the chamber, greatly reducing downtime.

2. Separation System

• Air Separation: Utilizing the density difference between metal and plastic, the light plastic particles are blown away through an adjustable air flow device (the wind speed is generally controlled at 15-25m/s), and the metal particles settle due to gravity, achieving preliminary separation.

• Magnetic Separation Module: For ferrous metals (such as the steel armor of armored cables), a high-intensity magnetic drum magnetic separator (magnetic field strength ≥ 8000Gs) is configured, which can efficiently separate ferrous metals from the mixture, with a separation purity of more than 98%.

• Electrostatic Separation (Optional): For the fine separation of copper, aluminum and plastic, a high-voltage electrostatic separator is used. Utilizing the difference in dielectric constant of different materials, metals and plastics are deflected and separated in the electric field, and the recovery rate of copper and aluminum can be increased to more than 95%.

• Dust Removal Device: Equipped with a pulse bag filter, it efficiently filters the dust generated during the shredding and separation process. The dust emission concentration is ≤ 30mg/m³, meeting the EPA environmental emission standards.

3. Application Scenarios and Industry Value

1. Waste Cable Recycling Plant

Concentrated shredding and separation of waste power cables, communication cables, and automobile circuit wires. Metals such as copper and aluminum are smelted again, and the plastic sheaths are granulated for the production of plastic products, realizing the dual improvement of "resource recycling + economic benefits". For example, processing 1 ton of waste copper cables can recover about 800kg of pure copper, with significant economic benefits.

2. E-waste Processing Center

It is matched with the "e-waste dismantling production line" to shred and separate small cables such as waste USB cables, lighting cables, and power cables, helping to achieve efficient recovery of precious metals (copper, aluminum) and plastics.

3. Collaborative Treatment of Multi-category Solid Waste

In addition to cables, the equipment can also be expanded to handle solid wastes such as waste home appliance casings (plastic/metal materials), waste tires, and waste circuit boards (PCB). By changing the cutter type and adjusting process parameters, "one machine with multiple functions" is realized, and the comprehensive processing capacity of the production line is improved.

4. Equipment Advantages and Selection Points

1. Core Advantages

• Efficient Shredding: The combined action of "shearing-tearing" of the double-shaft movable cutter ensures high cable shredding efficiency and uniform particles, and the processing efficiency is increased by more than 30% compared with single-shaft equipment.

• High Recovery Rate: The multi-stage separation technology (air flow + magnetic separation + electrostatic) works together, with a metal recovery rate of ≥ 95% and a plastic purity of ≥ 90%, far exceeding the industry average.

• Environmental Compliance: Equipped with a pulse bag dust removal system to effectively control dust pollution; the fully enclosed design reduces noise, meeting the OSHA industrial environmental protection requirements.

• Intelligent Operation and Maintenance: Some models are equipped with a PLC control system, which can real-time monitor parameters such as equipment current, temperature, and production capacity, realize fault early warning and automatic adjustment, and reduce the difficulty of operation and maintenance.

2. Selection Points

• Clarify the Materials to be Processed: According to the material (copper core/aluminum core, insulation type), specification (diameter, length), processing capacity of the cable to be processed, and whether it is necessary to expand the processing of home appliance casings, tires and other materials, select the model with the corresponding cutter type and configuration.

• Inspect Core Configurations: Pay attention to movable cutter material (AISI H13 is preferred), bearing brand (imported brands such as SKF and NSK are more reliable), and motor energy efficiency (Siemens/SIMO motors are energy-saving and stable), which directly determine the service life and operating cost of the equipment.

• Verify the Strength of the Manufacturer: Priority is given to manufacturers with independent research and development capabilities and perfect after-sales services (equipment commissioning, technical training, spare parts supply). You can request to visit the production workshop and case site to confirm their technical strength and project experience.

5. Frequently Asked Questions

1. Can the cable shredder handle wet or damp cables?

It is not recommended to process directly. Wet cables are prone to motor short circuits, cutter rust, and will reduce the separation effect. If processing is necessary, the cable moisture content should be reduced to below 10% through a drying equipment first.

2. What is the impact of cables with different insulation materials on the equipment?

◦ PVC insulated cables: A small amount of peculiar smell is easy to be generated during shredding, and it is necessary to ensure good ventilation of the production line;

◦ Rubber insulated cables: They are tough and require a high-torque cutter shaft and wear-resistant cutters;

◦ Cross-linked polyethylene insulated cables: They have high hardness, and carbide-coated cutters should be selected to enhance wear resistance.

3. How to improve the purity of metal separation?

The separation purity can be further improved by optimizing the wind speed of air separation, regularly calibrating the magnetic field strength of the magnetic separator, and configuring the electrostatic separation link.

4. What are the key points of equipment maintenance?

The core maintenance points include: regularly checking the wear of the movable cutter (when the wear amount is ≥ 2mm, it needs to be replaced/ground), cleaning the residual materials in the crushing chamber and separation system, adding lithium-based grease to the bearing every 500 hours, and checking the insulation performance of the electrical system.

Through the in-depth analysis of the cable shredder, it can be seen that it plays a core role in the process of "waste cable resource utilization". Choosing a cable shredder with strong adaptability and reliable performance will inject "efficient, environmentally friendly and profitable" strong momentum into your solid waste treatment project.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment