Against the backdrop of the global surge in electronic waste production, the electronic waste PCB shredder has emerged as a focal point in the environmental protection and resource recycling sector, thanks to its advantages in efficient crushing and precise sorting. This article will delve into the professional details and key points of this equipment from the perspectives of structural design, technical parameters, process applications, and core strengths.

1. Structural Design: Decoding the "Industrial Secret" of Efficient Crushing

The electronic waste PCB shredder adopts an integrated design of "shredding + crushing + sorting", with key components including:

• Shredding System: A set of shredding blades made of high-strength alloy, which initially crushes large materials such as PCB boards and waste household appliances into 10-50mm fragments through interlaced shearing motion. The blades feature a repairable design, reinforced for wear resistance through special heat treatment, ensuring a long service life and multiple regrinding cycles.

• Crushing Cavity: Equipped with a stainless steel screen, it refines materials to 5-15mm through secondary crushing by fixed and movable blades. The cavity is constructed from thickened manganese steel, capable of withstanding high torque impacts, making it suitable for the complex crushing scenarios of mixed metal and plastic materials in electronic waste.

• Power and Transmission System: Equipped with a Siemens Motor and Planetary Reducer, it achieves "low speed, high torque" power output, ensuring crushing efficiency while reducing equipment noise. The motor power meets North American NEMA standards and EU IE5 energy efficiency class requirements.

• Intelligent Control System: Based on PLC microcomputer full-automatic control, it enables one-button start, stop, reverse, and overload reverse protection. The control system is compatible with UL and CE certification standards, ensuring stable operation under complex working conditions.

2. Technical Parameters: Defining the "Hard Standards" for Industry Applications

The performance parameters of the electronic waste PCB shredder directly determine its processing capacity and application scenarios. Key indicators include:

• Feed Size: Supports direct feeding of materials ranging from 100mm to 3000mm, covering all types of electronic waste from mobile phone motherboards to waste refrigerators and washing machines. The feed inlet design complies with the American ANSI mechanical safety specifications and the EU Machinery Directive 2006/42/EC.

• Production Capacity: A wide range of 400-60,000kg/h, which can be flexibly selected according to production line scale, meeting the needs of small recycling workshops to large-scale resource factories. The capacity labeling conforms to the ASTM International Material Testing Standard Measurement Specifications.

• Applicable Materials: It is not only suitable for PCB circuit boards but also can handle lithium batteries, metal barrels, color steel tiles, car shells, aluminum plates, and other diverse materials, with strong material compatibility. The material processing range meets the category requirements for electronic waste treatment in the US RCRA regulations and the EU WEEE Directive.

• Environmental Indicators: The equipment operates at a noise level ≤80dB (complying with US OSHA noise exposure standards and EU EN ISO 11201 acoustic standards). Equipped with a Pulse Dust Collector for dust purification, the dust emission concentration is ≤10mg/m³ (meeting US EPA air quality standards and EU EN 15287 environmental emission requirements).

3. Process Application: A "Full-Process Solution" for E-Waste Resource Utilization

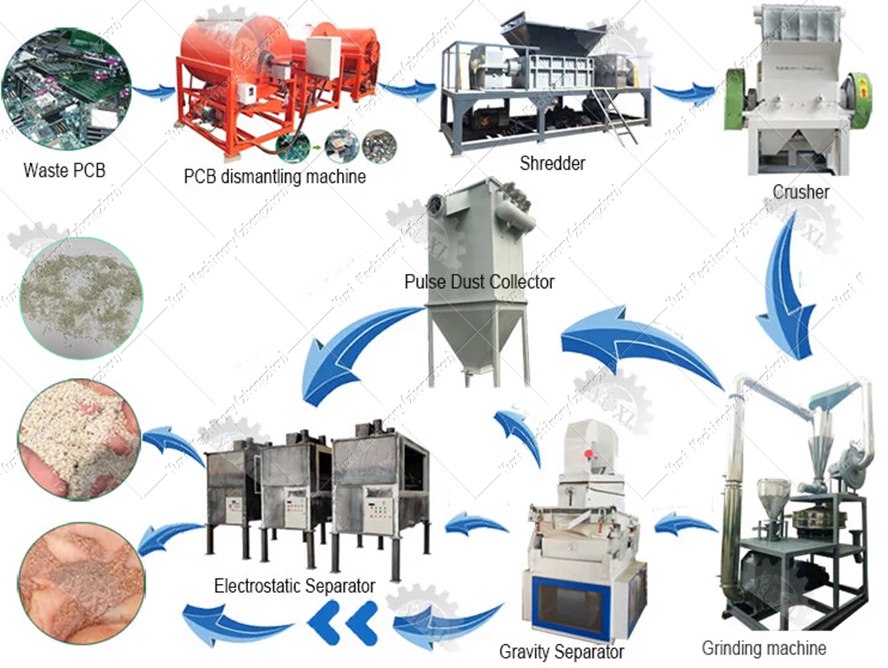

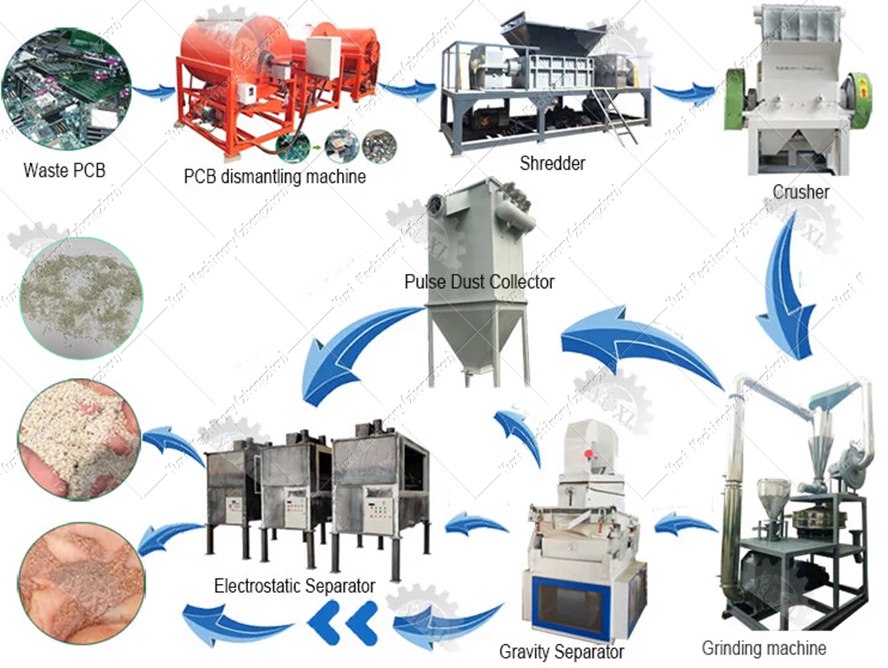

The electronic waste PCB shredder is not a single device but a core component of the e-waste crushing and sorting line. The typical process flow is as follows:

1. Pretreatment: Separate easily detachable components (such as batteries and cables) from large electronic devices through a PCB dismantling machine, with the dismantling process complying with the operating specifications of the US Institute of Scrap Recycling Industries (IRA) and the EU Circular Electronics initiative.

2. Shredding and Crushing: After initial shredding by a shredder, the materials enter the PCB crusher for refined crushing. The energy efficiency and safety of the crushing process meet the US DOE energy efficiency standards and the EU Eco-design Directive (EuP).

3. Sorting and Recycling: The crushed materials enter an Electrostatic Separator and Gravity Separator to achieve efficient separation of metals (gold, silver, palladium, copper, etc.) and plastics. If further material refinement is required, a Grinding Machine can be used for micron-level pulverization. The sorting accuracy meets the US ASTM D4101 material sorting standards and EU EN 15343 resource recycling purity requirements.

4. Core Advantages: Why It Is the "Preferred Equipment" in the Industry

The technical competitiveness of the electronic waste PCB shredder stems from the following core advantages:

• High Economic Efficiency: The repairable blades and low equipment failure rate significantly reduce operation and maintenance costs. The efficient sorting of metals and plastics directly increases the economic benefits of resource recycling. The benefit model conforms to the cost-benefit analysis standards of the US Circular Economy Industry Association (C2I) and the EU Ecodesign cost optimization framework.

• Strong Adaptability: It can handle electronic waste of different forms and materials "in one go" without frequent equipment replacement or parameter adjustment. Its adaptability complies with the US UL 1950 electronic equipment safety standards and EU EN 60204 mechanical and electrical safety specifications.

• Intelligent Operation and Maintenance: The PLC control system enables automated operation, combined with a three-level inspection system (weekly, monthly, and annual). For example, weekly inspections check for loose bolts and sensor status; monthly inspections detect blade wear; annual inspections involve comprehensive disassembly and cleaning of motors and reducers. The operation and maintenance standards are compatible with the US NFPA 79 electrical safety specifications and EU EN ISO 13849 mechanical safety control standards, ensuring long-term stable operation of the equipment.

5. Professional Q&A: In-Depth Answers to Help You Make Decisions

1. Q: What factors affect the service life of the blades of the electronic waste PCB shredder?

A: It is mainly affected by material hardness, feed uniformity, and daily maintenance. If the material contains a high proportion of hard metals or foreign objects (such as stones) are mixed into the feed, it will accelerate blade wear. Regular regrinding and timely cleaning of waste chips in the crushing cavity can effectively extend the blade life. The blade wear detection standards comply with the US ASTM E2255 wear test method and EU EN ISO 3164 surface wear measurement specifications.

2. Q: What environmental compliance designs does this equipment have?

A: In addition to the pulse dust collection system, the equipment's sealed crushing cavity prevents dust leakage. The low-noise transmission design meets the US OSHA 29 CFR 1910.95 noise exposure limit and EU EN 12012 acoustic environment standards. Meanwhile, the overload protection of the PLC system can avoid secondary pollution caused by equipment failures. Pollution prevention and control comply with US RCRA Subtitle C hazardous waste management and EU REACH regulations on the control of hazardous substance leaks.

3. Q: How do large-scale resource factories select equipment models?

A: It is necessary to consider the daily processing capacity, material types (such as the proportion of PCB boards and household appliance materials), and the connection requirements of the subsequent sorting process. Priority should be given to models with matching production capacity and compatible feed sizes, and corresponding shredders and sorting equipment should be matched to form a full-process production line. The production line design must meet the US NEPSI industrial equipment installation standards and EU EN 61439 electrical device assembly requirements.

With its technical features of "efficient crushing, intelligent control, and economic environmental protection", the electronic waste PCB shredder has become a core equipment in the e-waste resource utilization track. Whether it is an environmental protection enterprise laying out a resource utilization production line or a recycling organization upgrading its processing technology, it can rely on professional performance and flexible adaptability to help the industry advance on the dual tracks of "green development" and "resource circulation". Its technology and compliance deeply align with the stringent standards for e-waste treatment in the European and American markets, making it a preferred equipment for deploying global resource utilization industries.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment