In the field of electronic waste (e-waste) disposal, the Printed Circuit Board (PCB) shredder is a key technical equipment to break through the "waste siege" and achieve resource recycling. With its precise crushing process, it builds a "recycling bridge" for metal and non-metal resources in e-waste, serving as an indispensable core hub in the e-waste circular economy system.

1. Core Structure: The Technical Foundation for Industrial-Grade Crushing

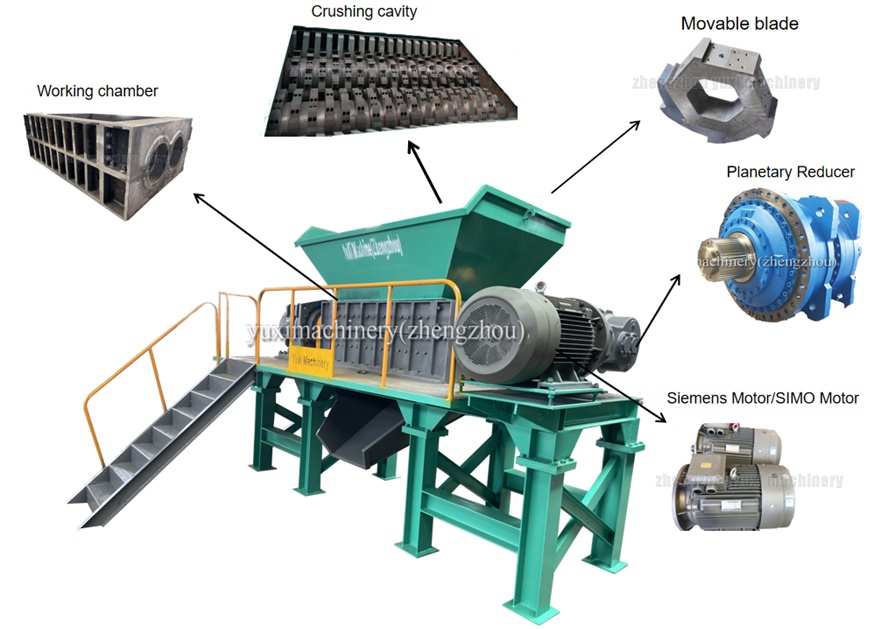

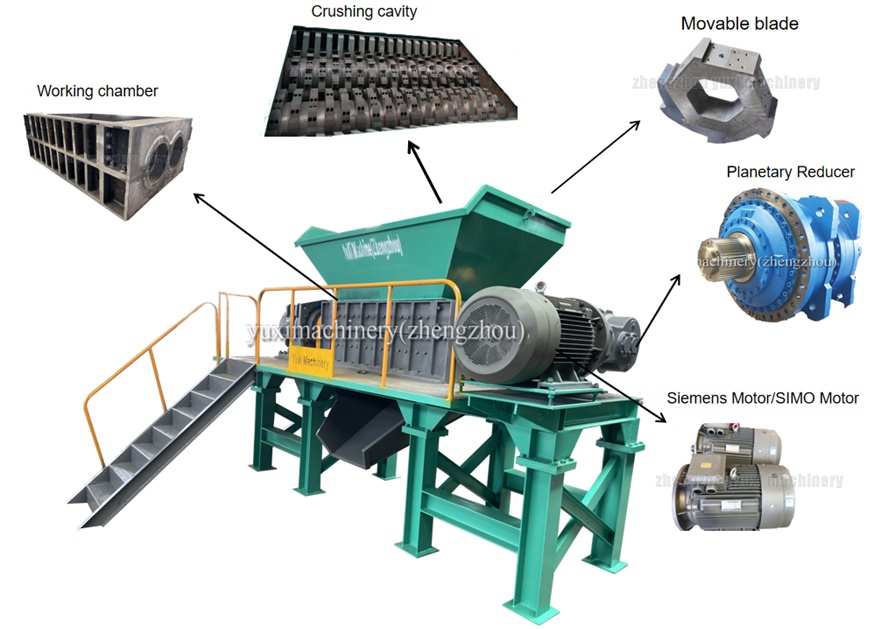

The electronic waste PCB shredder adopts a composite process of dual-shaft shredding + multi-stage crushing, with every structure designed for "efficient crushing and long-term operation":

• Alloy Shredding Blades: Made of high-wear-resistant alloy with a Rockwell hardness of HRC 60-65, supporting multiple repairs (both grinding and surfacing). A single set of blades can last over 8,000 hours, reducing consumable costs by approximately 60%-70% and significantly cutting down enterprise operating expenses.

• Heavy-Duty Bearing Housing and Manganese Steel Frame: The frame is integrally welded with 16Mn manganese steel, and the bearing housing is equipped with imported SKF heavy-duty bearings. It can withstand the instantaneous high torque generated when crushing hard PCBs, improving the equipment's continuous operation stability by 40%.

• Intelligent Power and Electrical Control System: Equipped with Siemens SIMO motors (power ranging from 15-315 HP) combined with planetary reducers, achieving precise "low-speed, high-torque" output. The PLC full-automatic control system supports one-key start/stop and overload reversal, with the equipment automation rate reaching 95%.

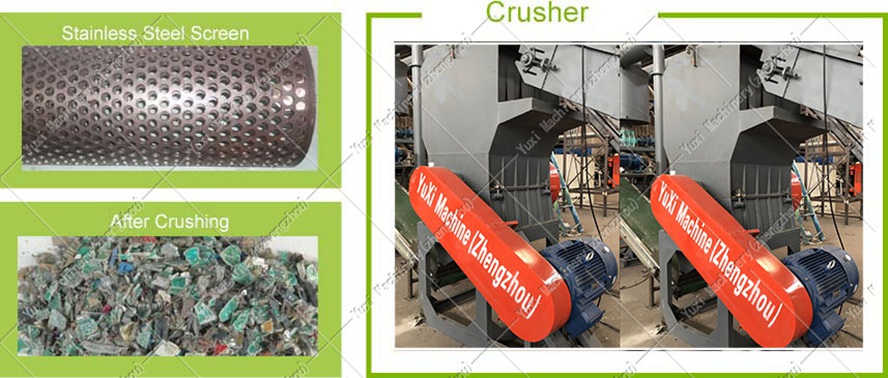

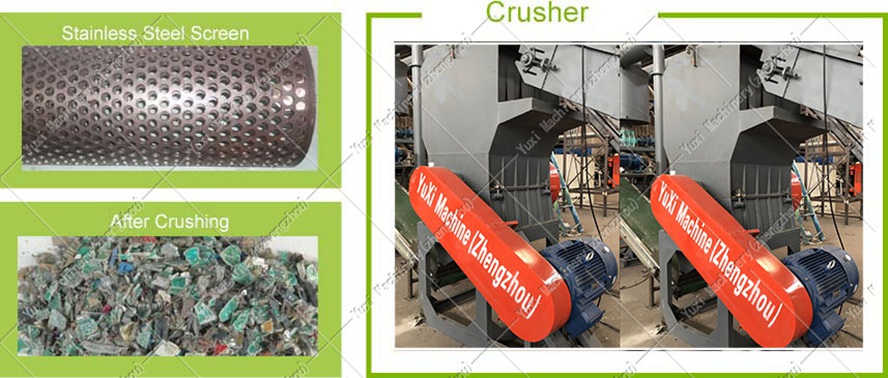

• Modular Crushing Chamber: Built-in staggered cutter sets perform three-stage processing of materials: "tearing - extrusion - crushing". The ASTM A240 standard stainless steel screen can be flexibly replaced, allowing precise control of the discharge particle size within the 5-20mm range.

2. Performance Parameters: Precisely Matching Industrial-Grade Needs

(1) Key Indicators

• Feeding Range: Capable of directly processing wide materials of 4-118 inches (such as entire TV sets and bundled PCB boards), eliminating tedious pre-processing.

• Processing Capacity: Covering a range of 0.44-66 tons per hour, suitable models are available for small recycling workshops to large resource recovery industrial parks.

• Environmental Performance: Operating noise ≤ 85 dB(A), and the pulse dust collection system ensures dust emission concentration ≤ 10 mg/m³, fully complying with the strict standards of the EPA and EU ETS.

(2) Material Compatibility

Its "capacity" is beyond imagination, handling from e-waste to mixed metal materials:

• Electronic products: PCB boards, lithium batteries, used mobile phones, computer hosts, etc.

• Home appliances: Dismantled materials from washing machines, refrigerators, TV sets, etc.

• Metal materials: Mixed materials such as metal barrels, color steel tiles, automobile frames, and aluminum plates.

3. Process Flow: A Complete Closed Loop for Resource Recovery

The electronic waste PCB shredder is the core of the "crushing - sorting" integrated production line, with a closely linked full process:

1. Dismantling Pre-Processing: PCB dismantling machines separate easily detachable components to reduce the subsequent crushing load.

2. Two-Stage Crushing: Shredders for coarse crushing → crushers for fine crushing, refining materials to the target particle size.

3. Dust Removal and Purification: Pulse dust collectors simultaneously capture dust to ensure no secondary pollution in the workshop.

4. Precise Sorting: Combined operation of gravity sorting and electrostatic sorting. Through the combined process of "physical sorting + electrostatic separation", efficient separation is achieved by utilizing the differences in density and electrical conductivity between metals and non-metals. The recovery rate of metals (gold, silver, palladium, copper, etc.) is ≥ 98%, fully meeting the resource recovery rate requirements of R2 and e-Stewards certifications.

This process transforms e-waste from an "environmental burden" into an "urban mine", increasing the processing profit per ton by 2-3 times.

4. Maintenance Management: Ensuring Long-Term Profitability of the Equipment

Establishing a hierarchical maintenance system is key to the stable operation of the equipment:

• Weekly Inspection: Check the tightness of bolts and nuts, the integrity of sensor leads, and monitor the noise and temperature of motors/reducers.

• Monthly Inspection: Measure the wear of blades (repair immediately when wear exceeds 0.2 inches) and evaluate the equipment vibration value.

• Annual Overhaul: Fully disassemble and clean bearings, replace waste lubricating oil, and comprehensively calibrate the electrical control system to ensure the equipment has a trouble-free operation time of ≥ 8,000 hours.

5. Commercial Value: Dual Guarantee of Compliance and Profitability

Against the backdrop of the global e-waste annual increment exceeding 50 million tons, the PCB shredder builds a "compliance + profitability" dual barrier for enterprises:

• Compliance: Fully meeting the requirements of U.S. RCRA, EU RoHS, WEEE Directive and other environmental regulations, avoiding the risk of huge environmental fines.

• Profitability: The high recovery rate of rare metals (≥ 98%) increases the processing profit per ton by 2-3 times. Meanwhile, the automated production line reduces labor costs by 50%, with the Overall Equipment Efficiency (OEE) ≥ 85%, enabling the investment payback period to be controlled within 2 years.

• Efficiency: The automated production line reduces labor costs by 50%, with an Overall Equipment Efficiency (OEE) ≥ 85%, leading the industry in production line operation efficiency.

Questions and Answers

1. How much can the "repairable" design of high-wear-resistant alloy blades reduce consumable costs for enterprises within an 8,000-hour service life?

Answer: It can reduce consumable costs by approximately 60%-70%.

2. What is the technical logic behind the metal recovery rate of ≥ 98% after the full "crushing - sorting" process of electronic waste?

Answer: Through the combined process of "physical sorting + electrostatic separation", efficient separation is achieved by utilizing the differences in density and electrical conductivity between metals and non-metals.

3. How can this equipment achieve the commercial goal of recovering investment costs within 2 years while meeting strict environmental regulations in Europe and the United States?

Answer: The high recovery rate of rare metals (≥ 98%) increases the processing profit per ton by 2-3 times. At the same time, the automated production line reduces labor costs by 50%, with an Overall Equipment Efficiency (OEE) ≥ 85%, thus realizing the rapid recovery of investment costs.

The electronic waste PCB shredder is by no means a simple "crushing tool", but a technical and commercial engine for e-waste resource recovery. With its full-link capabilities of "efficient crushing + precise sorting + long-term maintenance", it helps enterprises tap into the "metal gold mines" and "plastic gold mines" in e-waste while adhering to environmental compliance red lines. For enterprises layouting the global e-waste recycling industry, it not only represents technical competitiveness but also serves as a core tool to achieve the "win-win" of environmental responsibility and commercial value.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment