In the scrap recycling and metallurgical processing sectors, the hydraulic metal baler is a key asset for reducing costs and increasing efficiency. However, practitioners often struggle with questions like: How to choose equipment that fits the site? How to compress materials to maximize transportation efficiency? This article addresses these core issues, dissecting the professional details of hydraulic metal balers from technical principles, scenario adaptation to cost optimization, to help you achieve dual improvements in efficiency and profit in the material processing link.

1. Technical Principles: Understand the "Magic of Force" to Choose the Right Equipment Without Pitfalls

The core of a hydraulic metal baler is the hydraulic transmission system—it converts the kinetic energy of an electric motor (or diesel engine) into hydraulic energy, and then outputs ultra-high extrusion force (200-500 US tons) through hydraulic cylinders to "press loose scrap metal, waste paper, etc. into iron lumps".

This is powered by Pascal's law: the pressure of hydraulic oil is transmitted uniformly, allowing the equipment to "amplify" the force several times. Simply put, even lightweight aluminum scrap can be pressed into high-density material blocks. This is the key to saving transportation costs for you—the volume is reduced by more than 60%, and the number of trips is directly halved!

2. Core Features: Target Industry Scenarios to Solve "Difficult Installation, Lack of Power, and Troublesome Discharging"

1. Installation & Power: Adapt to Diverse Sites

No need for foundation pouring or foot screws; it can be installed just by moving it with a forklift, saving site modification costs. The power can be a 30-75 HP electric motor (the first choice for factories/recycling stations with convenient electricity access), or it can be replaced with a diesel engine (directly activating remote sites and temporary operations).

2. Discharging & Operation: Multiple Modes to Deal with Different Processes

Discharging can be automatic dropping in "dump mode", pushing out material blocks in "push rod mode", or manual packaging—whether you are in assembly line operation or small-batch recycling, there is always a way to adapt to your production line. The joystick design complies with safety operation specifications, and novices can get started quickly, eliminating operation accidents.

3. Customization & Durability: Let the Equipment Be "Tailor-Made" for You

Both the machine size and bale size can be customized. Material blocks ranging from 30×30×60 inches to 48×48×96 inches fit perfectly into common shipping containers. The push cylinder and push head are connected by a spherical structure, which directly extends the service life of the hydraulic oil seal by 30%. Less machine repair means more money.

4. Efficiency & Low Noise: Balance Production Efficiency and Compliance

After the feeding port is widened, the feeding speed is increased by 30%. The noise of the hydraulic system is controlled below 85 decibels, fully complying with industrial noise standards, so you no longer have to worry about the environmental protection department visiting.

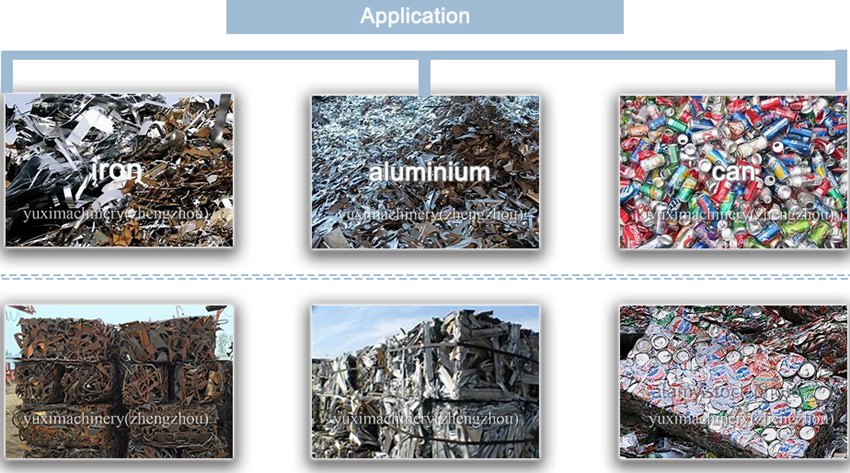

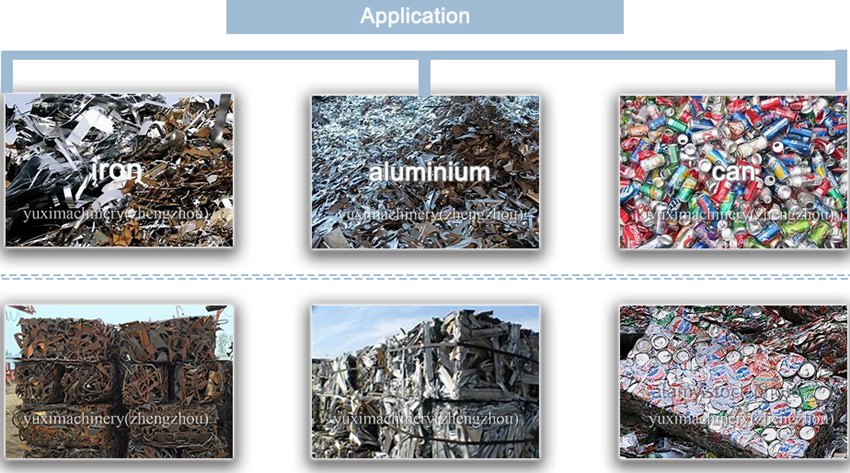

3. Application Scenarios: Precisely Match Industries and Tell You "How to Press Different Materials"

• Metallurgical & Recycling Industry: Scrap steel, scrap aluminum, scrapped auto parts, after being pressed into furnace charge, the smelting cost is reduced by 20%;

• Waste Paper & Plastic Industry: Cartons and plastic bottles are pressed into blocks, the storage space is halved, and the transportation cost is directly cut in half;

• Agricultural Field: Straw and cotton are pressed into bales, meeting waste disposal requirements, and can also be sold to biomass power plants for additional income.

4. Cost and Value: Calculate the Account Clearly and Turn Equipment Investment into a "Money Tree"

Buying equipment is not spending money, but investing—hydraulic metal balers allow you to:

• Reduce transportation costs by 50% (high material block density, one truck can carry the amount of two trucks before);

• Reduce storage costs by 40% (reduced volume, the warehouse can store twice as much goods);

• Reduce maintenance costs by 30% (spherical connection + durable oil seal, less failure and long service life).

Moreover, the technical level is comparable to first-tier brands, and the environmental management system is fully met. Whether it is a listed company or a small workshop, it can rely on it to enhance industry competitiveness.

Q&A Session: Identify Your Most Concerned Questions and Explain Them Clearly at Once

1. What is the motor power selection? How to choose the power source?

The 30-75 HP motor covers most scenarios. Choose the motor if electricity is convenient; if there is no power supply in remote sites, replace it with a diesel engine, and the power is just as strong.

2. How tight should the material block be pressed to save the most money?

It depends on downstream demand! If you sell to a smelter, press it until "it doesn't loosen in the furnace". If you sell to a recycler, press it until "it doesn't take up space in transportation". The equipment can customize the bale size, fully according to your needs.

3. Can small workshops afford it? What is the payback period?

Customization can choose the "entry-level configuration", and the transportation and storage costs saved can be recovered in half a year, and then all are pure profits.

After reading this, are you clear about how to "choose, use, and make money" with hydraulic metal balers? Choose the right equipment, and the efficiency and profit of scrap metal recycling and material processing can really be "pressed out"!

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment