I. Real Challenges and Industry Cases in Can Crushing

Can crushing may seem simple, but it is actually a critical link in the production line. Whether it's metal can waste from food processing plants or PET bottles from beverage factories, how to efficiently and cleanly crush and process directly affects the efficiency and cost of the entire production process.

Case Study: A canned fruit and vegetable company incurred an additional labor cost of $5,000 per month due to improper equipment selection. After switching to a professional can crusher, crushing efficiency increased by 40%, energy consumption decreased by 22%, and the equipment cost was recovered within six months.

Another Case: A large brewery once experienced an 8-hour production line shutdown due to a crusher equipment failure, resulting in losses of up to $83,000. Later, by adopting a crusher with an intelligent monitoring system, downtime was reduced to less than 15 minutes through real-time data early warning.

II. Core Principles and Technical Details of Can Crushers

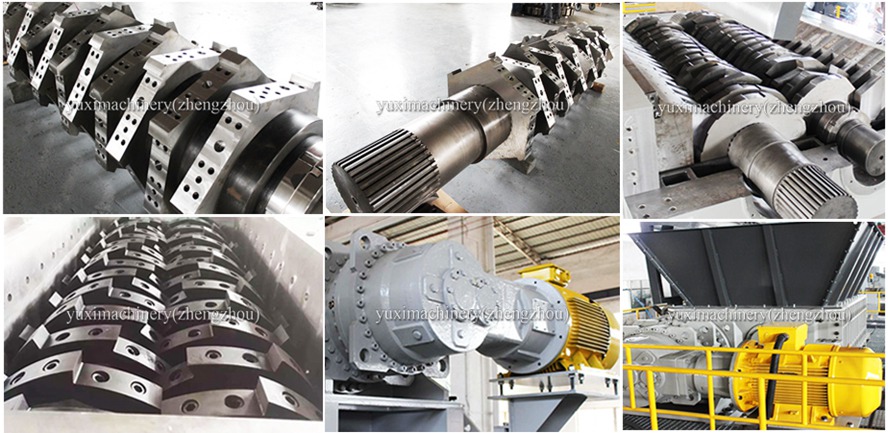

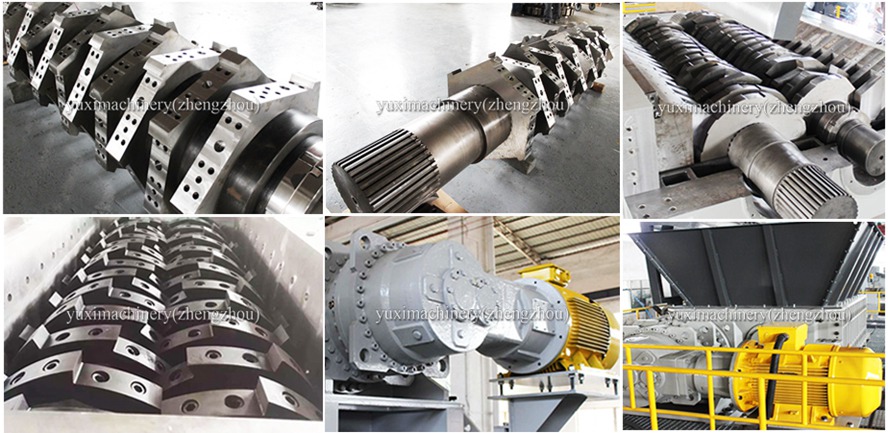

1. Crushing Process and Mechanical Structure

• Feeding System: Designed to handle various materials, from cans to plastic containers, equipped with anti-jamming devices and automatic feeding systems.

• Cutting Mechanism: Uses a single rotating shaft with sharp interlocking blades to pull materials into the cutting zone; blade angles can be adjusted to accommodate different material hardness.

• Screening System: Separates crushed materials by size to ensure consistent output; screens can be quickly replaced to meet different particle size requirements.

• Dust and Odor Control: Integrates a negative pressure dust collection system and activated carbon deodorization device to ensure the workshop environment meets occupational health standards.

2. Key Performance Indicators

• Capacity Matching: Select models based on material type and required throughput (wet materials ≤3 t/h, dry materials up to 8 t/h).

• Blade Life: Uses tungsten carbide blades, with a lifespan of ≥2,000 hours when processing steel cans; regular sharpening can extend this to over 3,000 hours.

• Energy Efficiency: Variable frequency motor + hydraulic drive, no-load current ≤30% of rated value, full-load efficiency ≥85%.

• Noise and Vibration: Through dynamic balance design and vibration isolation devices, noise is controlled below 85 dB, and vibration acceleration ≤1.5 m/s².

III. Five-Step Scientific Selection Method

1. Assess Material Properties

• Material: Different blade angles and hardness are required for tinplate, aluminum cans, composite materials, PET bottles, etc.

• Form: Flattened cans, whole cans, liquid-containing cans, label status, etc., correspond to different feeding systems and pretreatment devices.

• Impurities: Special materials containing sand, salt, acid, etc., require additional pretreatment and wear-resistant design.

2. Determine Processing Scale

• Small-Scale Production: Choose vertical single-shaft models with 1–2 t/h capacity, occupying ≤5 m².

• Medium-to-Large Production: Prioritize horizontal dual-shaft models with hydraulic feeding systems, handling 3–8 t/h, requiring ≥10 m² of operation space.

• Continuous Production Line: Integrate automatic conveying, metal detection, weight sorting, and other pre- and post-processing equipment.

3. Verify Equipment Qualifications

• Certifications: Check CE, ISO 9001, ISO 14001, etc., focusing on dust explosion protection (ATEX) and noise control indicators.

• Manufacturer: Verify possession of pressure vessel design and manufacturing qualifications, and successful cases of similar equipment for more than three years.

• After-Sales Service: Require a 48-hour on-site service commitment and key spare parts inventory guarantee.

4. Test and Observe Performance

• Initial Test Run: Operate continuously for 4 hours, monitoring current fluctuations (≤±5%), temperature rise (≤40°C), and dust concentration (≤10 mg/m³).

• Long-Term Tracking: Tool wear rate ≤0.1 mm/day, bearing temperature ≤70°C, no abnormal vibration or noise.

• Energy Efficiency Test: Deviation between actual and theoretical energy consumption ≤10%, qualified crushed particle size rate ≥95%.

5. Economic Analysis

• Payback Period: Calculate equipment investment, operation and maintenance costs, labor savings, and waste value increase, with a reasonable payback period ≤3 years.

• Life Cycle Cost: Consider spare parts replacement, energy consumption, maintenance, and downtime losses to select the lowest comprehensive cost solution.

IV. Common Industry Misconceptions and Avoidance Traps

1. The "One-Size-Fits-All" Trap

A company used a general-purpose crusher for aluminum cans, leading to frequent jams due to insufficient feed opening size, with repair costs eventually exceeding the original equipment value.

Avoidance Method: Adhere to "one material, one discussion," conduct small sample tests for each material to confirm crushing effect and equipment stability.

2. Neglecting Pretreatment

Direct crushing of liquid-containing cans can easily cause motor overload and material blockage.

Avoidance Method: First remove over 90% of free liquid through a dewatering device; gas-containing cans need to be vented first; acid-containing materials require corrosion-resistant design.

3. Key Equipment Maintenance Details

• Tool Clearance: Check every 8 hours, maintain at 0.5–1.0 mm, measured accurately with feeler gauges.

• Bearing Lubrication: Use lithium-based grease; shut down for inspection if temperature exceeds 60°C, replenish grease every 200 hours.

• Screen Replacement: Clean the screen before shutdown, use special tools for replacement to ensure proper installation.

4. Neglecting Intelligence and Data Management

Modern crushers should be equipped with IoT modules to monitor current, temperature, vibration, etc., in real time; predictive maintenance can reduce downtime by more than 30%.

V. Frequently Asked Questions

Q1: Can can crushers handle cans with labels?

A: Yes, but models with a "label stripping-wind separation" module are needed. It is recommended to remove labels by hot alkaline water soaking or high-speed friction stripping during pretreatment.

Q2: How to balance crushing fineness and capacity?

A: Use "two-stage crushing"—coarse crushing to 30–50 mm, then fine crushing to 5–10 mm, which can increase capacity by more than 20%. It can also be achieved by adjusting blade speed and screen aperture.

Q3: How to efficiently sort crushed metal cans?

A: Use a combination of "magnetic separation + eddy current separation + density wind separation," achieving ≥98% aluminum recovery and ≥99% iron recovery. For complex materials, photoelectric sorting and X-ray sorting can be added.

Q4: What are the special installation requirements?

A: A vibration-damping foundation (thickness ≥200 mm) is required, and a metal detector should be installed at the feed inlet to prevent hard foreign objects. Sufficient maintenance space and lifting points should be reserved in the workshop.

Q5: How to reduce dust and noise during crushing?

A: Use negative pressure dust collection (air volume ≥1,000 m³/h) and soundproof enclosures to ensure dust ≤10 mg/m³ and noise ≤85 dB in the operating area. Optimize the crushing chamber design to reduce material collision noise.

VI. Conclusion: From Pain Points to Solutions

Selecting a can crusher is not just equipment procurement but a system optimization of the production line. When you consider crushing, sorting, dust removal, and deodorization as a whole, you can truly achieve the goal of "efficiency, cleanliness, and low cost."

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment