Global e-waste generation has exceeded 50 million tons annually, with printed circuit boards (PCBs) serving as the "nervous system" of electronic devices. They contain precious metals like gold, silver, and copper, while also harboring hazardous substances such as lead and cadmium. As electronic devices are updated more frequently, finding efficient and environmentally friendly ways to handle discarded PCBs has become an urgent industry challenge.

The emergence of e-waste PCB shredders provides a precise solution to this complex problem. They not only effectively recover precious metals but also significantly reduce harmful substance emissions, aligning with global trends in circular economy and environmental protection.

E-waste PCB shredders employ a combined process of multi-stage shredding and air separation to break down PCBs into metal and non-metal components. Typical equipment configurations include:

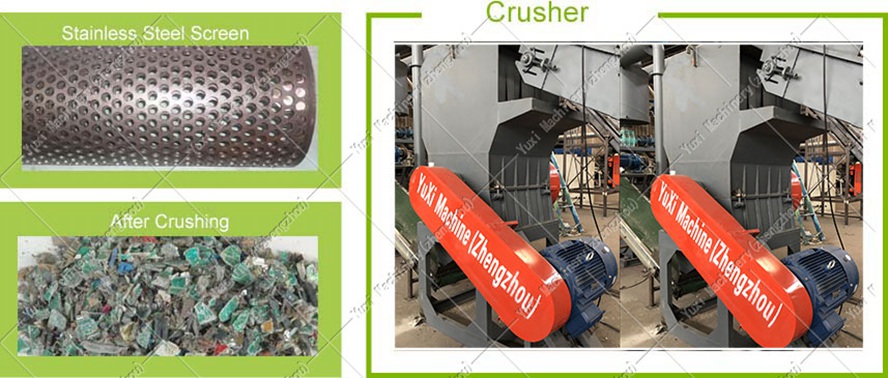

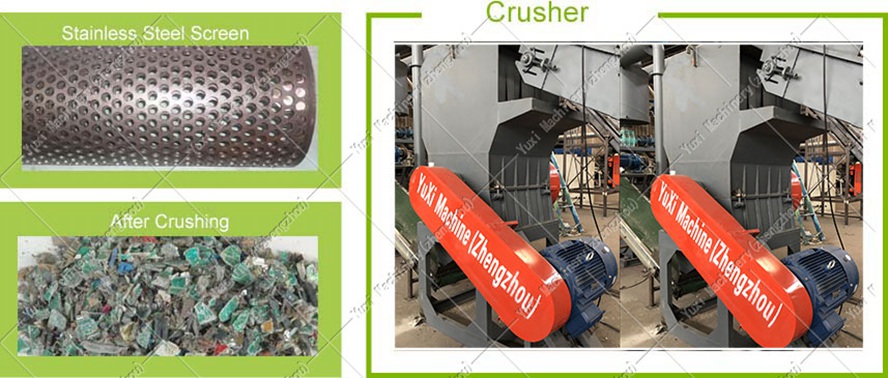

• Shredding Blade System: Made from high-wear-resistant alloy materials, offering long service life and multiple repair capabilities

• Bearing Box and Chassis Support: Thick and sturdy frame capable of withstanding high torque

• Feeding System: Equipped with intelligent controls to ensure uniform feeding

• Power System: Uses Siemens motors and planetary reducers for strong and stable power

• Electrical Control System: Microcomputer (PLC) automatic control enabling start, stop, reverse, and overload reverse functions

Technical features include:

• Low-speed (20-60 rpm), high-torque design ensuring sufficient material shredding while minimizing metal loss

• Compact structure, small footprint, and low noise (<85 dB)

• High degree of automation, significantly reducing labor costs

• Dust emissions <10 mg/m³ with efficient pulse bag dust collection system

Processing flow:

1. Pretreatment: Remove batteries, capacitors, and other hazardous components

2. Primary Shredding: Reduce PCBs to approximately 50 mm

3. Secondary Grinding: Further reduce material size to <2 mm

4. Separation: Combine eddy current separation, air classification, and near-infrared optical sorting

5. Metal Recovery: Separate and recover non-ferrous metals, ferrous metals, and non-metals

Investment composition:

• Equipment investment: Approximately 30-50% of total project cost

• Plant and infrastructure: Approximately 20-30%

• Working capital: Approximately 10-20%

• Other expenses: Approximately 10-20%

Operating costs:

• Labor costs: High automation reduces labor requirements

• Energy costs: Approximately 20-30% of operating costs

• Maintenance costs: Regular maintenance can effectively control costs

• Raw material costs: E-waste procurement costs

Return on investment: With stable raw material supply and metal prices, the payback period typically ranges from 2-4 years. A 10% increase in gold and silver prices can shorten the payback period by approximately 6-12 months.

Safe operating procedures:

1. Pre-start inspection: Ensure all protective devices are in place, lubrication systems are normal, and emergency stop devices are functional

2. No-load startup: Observe current and noise to confirm smooth equipment operation

3. Feeding control: Maintain uniform feeding, avoid overloading, and use frequency control or weigh feeders

4. Shutdown procedure: Stop feeding first, allow material to clear before shutting down, and perform necessary cleaning

Routine maintenance:

• Daily inspection: Blade wear, bearing temperature, and lubrication status

• Weekly inspection: Check for loose bolts/nuts, damaged sensor leads, and proper reducer/motor operation

• Monthly inspection: Assess wear and adjust blade clearances as needed

• Annual inspection: Comprehensive inspection, cleaning of motors, reducers, and crusher roll bearings, and lubricant replacement

Troubleshooting:

• Establish a robust fault diagnosis system for quick identification and resolution

• Stock necessary spare parts to minimize downtime

• Train professional maintenance personnel or enter into maintenance agreements with equipment suppliers

Q1: Can PCB shredders handle all types of e-waste?

A: No. PCB shredders are designed specifically for printed circuit boards. Electronic devices containing large quantities of batteries, capacitors, or other hazardous components require pretreatment to remove these parts. Special handling may be needed for PCBs containing brominated flame retardants.

Q2: How to ensure environmental compliance during processing?

A: Comprehensive dust collection and water treatment systems must be installed to ensure emissions <10 mg/m³. Monitor heavy metals and persistent organic pollutants during processing. Consider conducting a Life Cycle Assessment (LCA) to fully evaluate environmental impacts.

Q3: How to improve metal recovery rates?

A: Optimize particle size, adjust separation parameters, and maintain good equipment operation. Regular calibration of separation equipment can significantly improve recovery rates. Multi-stage separation and manual inspection/rework can further enhance recovery.

Q4: What are the advantages of mechanical physical separation compared to pyrometallurgy?

A: Mechanical physical separation avoids air pollution and metal loss associated with high-temperature processing, making it particularly suitable for small-batch, multi-variety PCB processing. It typically has lower capital and operating costs and smaller environmental impact.

E-waste PCB shredders represent not just a technological investment, but also a corporate commitment to circular economy and environmental responsibility. Through professional equipment selection and standardized operations, businesses can achieve environmental benefits while gaining significant economic returns. As technology advances and policy environments improve, the PCB recycling industry will see broad development prospects.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment