In the medical field, every surgery and every treatment generates a significant amount of medical waste. These seemingly ordinary waste materials can become a "time bomb" for disease transmission. In 2018, a top-tier hospital experienced an outbreak of nosocomial infections due to improper medical waste disposal, drawing widespread public attention. This incident not only highlighted the importance of medical waste management but also made people realize the indispensable role of medical waste shredders.

I. Understanding

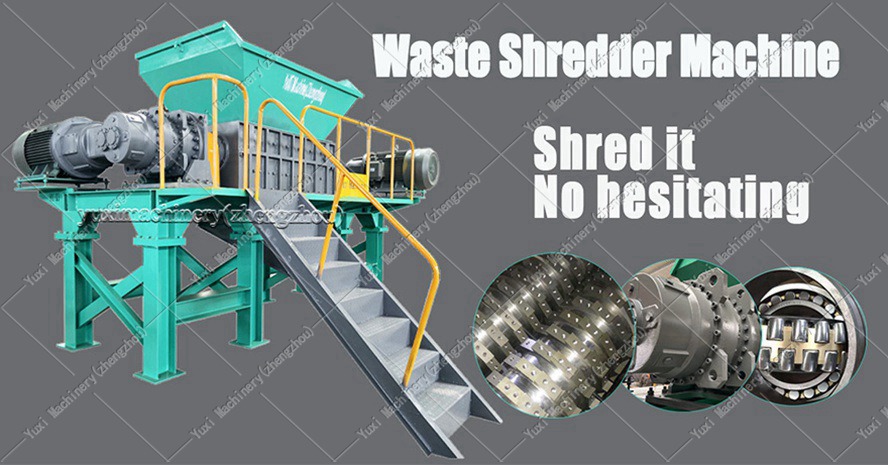

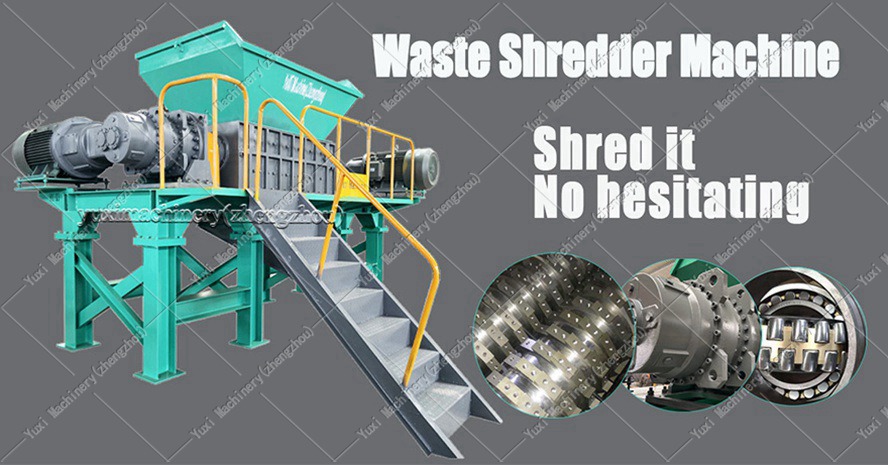

A medical waste shredder is a specialized device for processing medical waste. It uses powerful shredding capabilities to transform various medical wastes—from disposable needles and expired medications to infectious dressings and pathological specimens—into harmless particles. This process not only greatly reduces waste volume and lowers transportation and disposal costs but also effectively prevents the spread of pathogens, protecting both the environment and public health.

Working Principle

The core of a medical waste shredder lies in its efficient shredding system. It typically features high-strength blades and a precision shredding chamber, enabling rapid fragmentation of various medical wastes into fine particles. Many modern devices also integrate disinfection functions, such as high-temperature steam or chemical disinfection, ensuring thorough pathogen elimination during the shredding process.

Core Advantages

1. Efficient Processing: Handles large volumes of medical waste quickly, significantly improving work efficiency.

2. Safety Assurance: Uses a sealed design and multiple safety protections to prevent operators from contacting hazardous waste.

3. Environmental Compliance: Meets strict environmental standards to reduce pollution.

4. Cost Savings: Reduces waste volume, lowering transportation and disposal costs.

II. Main Functions

1. Immediate and Efficient Processing

A key advantage of medical waste shredders is their ability to provide immediate and efficient waste processing for healthcare facilities. The blade system can rapidly fragment various medical wastes, reducing their volume by up to 90%. This not only significantly reduces storage needs but also decreases transportation frequency and costs.

Scientific Principle: The design of high-strength blades and a precision shredding chamber ensures rapid and uniform waste fragmentation. Many devices are equipped with intelligent control systems that automatically adjust shredding parameters based on waste type for optimal results.

Application Scenarios: This equipment is particularly suitable for large hospitals, clinics, and laboratories that generate significant medical waste. It can quickly handle backlogged waste during peak periods (e.g., post-surgery or during infectious disease outbreaks), preventing accumulation and potential infection risks.

2. Enhanced Biosafety

Medical waste shredders significantly reduce the risk of pathogen transmission through efficient fragmentation and disinfection. This protects both healthcare workers and patients while reducing environmental pollution.

Scientific Principle: During shredding, waste is broken into fine particles, increasing the contact area with disinfectants and improving disinfection effectiveness. The sealed design prevents waste leakage during processing, ensuring operator safety.

Usage Method: Sort medical waste and feed it into the shredder. Start the device for fragmentation and disinfection. After processing, transfer the harmless particles to dedicated containers for further disposal.

3. Improved Compliance and Transparency

Modern medical waste shredders are often equipped with detailed operation records and monitoring systems, ensuring healthcare facilities can easily meet the compliance requirements of environmental and health authorities. This helps avoid fines and legal disputes while enhancing the institution’s public image.

Scientific Principle: Intelligent control systems record processing time, waste type, and parameters for each operation, generating detailed reports. These data can be used for internal audits and external inspections, ensuring operational transparency and compliance.

Usage Method: Regularly generate and review operation reports to ensure all processes meet regulatory requirements. Additionally, perform regular maintenance and calibration to ensure continuous and efficient operation.

III. Application Cases

Case 1: Infection Control in a Top-Tier Hospital

In 2019, a top-tier hospital introduced advanced medical waste shredders. Previously, manual handling of infectious waste had led to multiple healthcare worker infections. The new equipment not only significantly improved processing efficiency but also effectively prevented pathogen transmission through its sealed design and automatic disinfection function. Within one year, the hospital’s nosocomial infection rate decreased by 30%, significantly enhancing healthcare worker safety.

Case 2: Cost Savings for a Community Clinic

A community clinic in a suburban area struggled with high medical waste transportation costs. After introducing a medical waste shredder, waste volume decreased by 80%, and transportation frequency dropped from three times weekly to once weekly, saving approximately ¥20,000 annually. The equipment’s efficient processing capabilities also ensured the clinic remained environmentally compliant, avoiding potential fines.

IV. Maintenance and Upkeep

To ensure the long-term, efficient operation of medical waste shredders, regular maintenance is crucial. Key maintenance points include:

1. Daily Inspection: Check for abnormal noise, vibration, or overheating before and after each use. Ensure no foreign objects remain in the blades or shredding chamber.

2. Regular Cleaning: Thoroughly clean the equipment (especially the shredding chamber and blades) weekly or monthly, depending on usage frequency, to prevent waste buildup and bacterial growth.

3. Blade Maintenance: Regularly inspect blade wear and replace or sharpen as needed to ensure shredding effectiveness.

4. Lubrication System: Lubricate bearings and transmission components as recommended by the manufacturer to reduce wear.

5. Electrical System Inspection: Regularly check the electrical system to ensure secure connections and no short circuits or overload risks.

6. Professional Maintenance: Schedule at least one professional maintenance visit annually for a comprehensive inspection and necessary repairs to ensure continuous operation.

V. Frequently Asked Questions (FAQ)

1. Is it suitable for all types of healthcare facilities?

Yes, medical waste shredders are suitable for facilities of all sizes, including large hospitals, small clinics, and laboratories. However, choose a model based on waste type and volume. For example, large hospitals may need higher-capacity equipment, while small clinics can opt for more compact, cost-effective models.

2. How long should it run?

Most medical waste shredders run for 5–15 minutes per cycle, depending on waste type and volume. Prolonged operation may cause overheating and reduce lifespan. Follow the manufacturer’s instructions and actual needs to schedule run times.

3. Can it be used daily?

While medical waste shredders can be used daily, frequency depends on waste generation and equipment capacity. Daily use is necessary for high-waste facilities, while small clinics may only need it every few days. Follow the manufacturer’s recommendations to avoid overuse and damage.

4. What are the potential risks?

Medical waste shredders are generally safe but carry risks: improper operation may cause mechanical injuries; handling hazardous waste (e.g., radioactive or chemical materials) may require additional safeguards. Operators should receive professional training and follow safety procedures.

5. Can it be used with other waste processing equipment?

Yes, medical waste shredders can integrate with other equipment (e.g., sterilizers or incinerators) for comprehensive waste management. They work best with sterilization equipment. However, use caution with highly corrosive or radioactive waste, as these may increase wear or safety risks. Any new equipment combinations require prior safety assessments and testing.

VI. Conclusion

Medical waste shredders are critical for medical safety and environmental protection, as well as for improving efficiency, reducing costs, and ensuring compliance in healthcare facilities. From large hospitals to small clinics, they play an irreplaceable role. By understanding their working principles, functions, and application cases, healthcare facilities can better select and use these devices to protect patients, staff, and the environment.

When choosing a medical waste shredder, consider processing capacity, safety, compliance, and cost-effectiveness. Regular maintenance and operator training are also key to long-term, efficient operation.

Whether you manage a healthcare facility or care about medical safety and the environment, understanding the importance and details of medical waste shredders will help drive sustainable development in healthcare and overall public health.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment