Description: What type of plastic shredder should you choose? This article breaks down the principles of dual-shaft/single-shaft shredders, 2 factory recycling cases, includes a selection table + maintenance guide, and helps you boost waste processing efficiency.

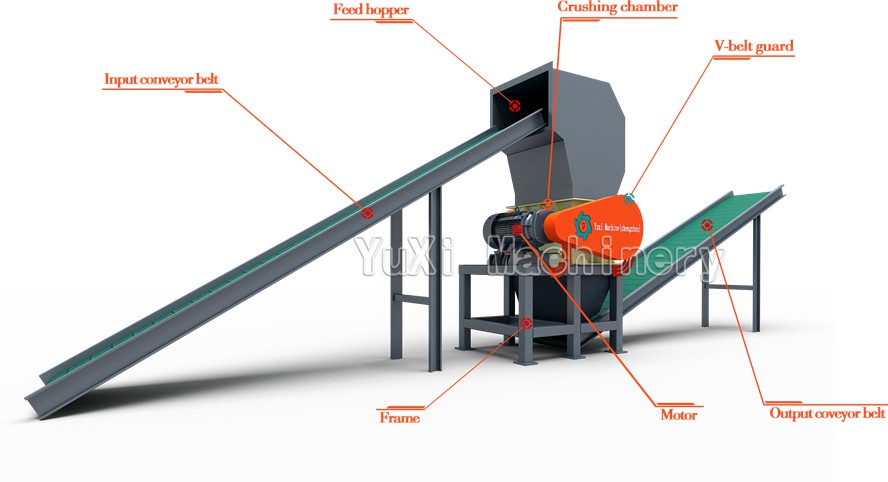

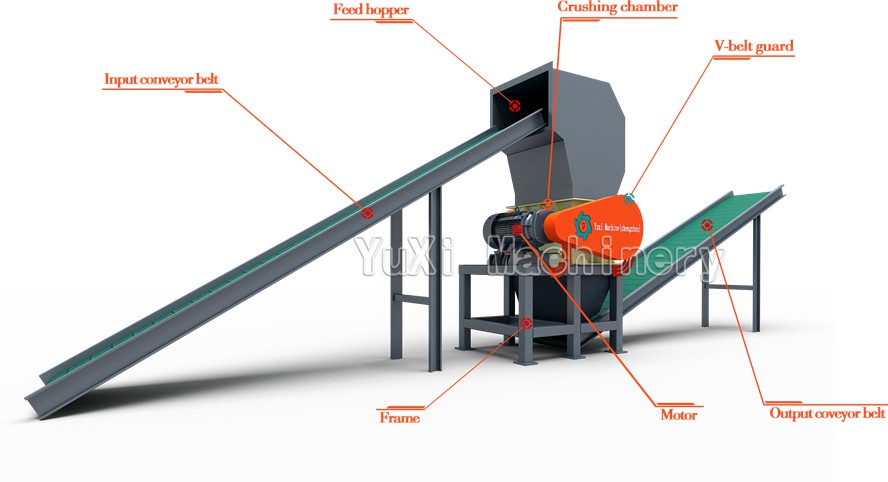

1. What Is a Plastic Shredder? Core Principles & Components

(Directly addresses search intent upfront)

A plastic shredder is equipment that processes industrial plastic waste (e.g., PVC pipes, electronic casings) into 0.4–2 inch particles via shearing, tearing, and extrusion—it’s a core tool in the recycling workflow.

Its core principle is interlocking dual-shaft/multi-shaft blade cutting: High-hardness 4140 alloy steel blades grip materials, adjustable gaps control particle size, and a motor + gearbox deliver high torque (20–270 HP) to accommodate different plastic types.

Key components include:

1. Cutting Chamber: Wear-resistant A36 steel liners + feed hopper, compatible with various waste forms;

2. Drive System: PLC control + overload protection to prevent damage from metal contaminants;

3. Discharge Unit: Screens for particle uniformity, directly connecting to subsequent pelletizing processes.

2. How to Use a Plastic Shredder? 2 Real Factory Cases

(Covers the long-tail keyword "plastic shredder application cases")

Case 1: Packaging Waste Processing in a FMCG Factory (PE Film + PET Bottles)

A food factory in California, USA, generates 5 tons of packaging waste daily. Before using a dual-shaft shredder:

• Waste occupied 860 sq ft of warehouse space, with manual sorting costs of $450/month;

• Transportation required 2 trucks/day, costing $1,800/month.

After using a dual-shaft shredder (capacity: 2 tons/hour):

• Waste volume was reduced by 70%; compressed bales only needed 1 truck every 2 days;

• Particles sold to a recycling plant generated $1,200/month in additional revenue;

• Labor costs dropped by 60%, and the equipment paid for itself in 3 months.

Case 2: Plastic Casing Processing in an E-Waste Recycling Plant (ABS + PS)

An e-waste recycler in North Rhine-Westphalia, Germany, processes 3 tons of old appliance casings daily. Pain points:

• Mixed plastics + embedded metal parts limited manual disassembly efficiency to 0.5 tons/day;

• Low waste purity led to a recycling price of only $170/ton.

Solution: Multi-shaft shredder with metal separation:

• First shredded into 0.8-inch particles; sensors separated metal, achieving 98% purity;

• Processing efficiency increased to 3 tons/day, and the recycling price rose to $290/ton;

• Monthly profit increased by €3,500.

3. Plastic Shredder Selection: How to Choose Between 3 Types? (With Comparison Table)

(Covers long-tail keywords "plastic shredder selection" and "dual-shaft vs single-shaft shredders")

| Shredder Type | Core Advantages | Suitable Materials | Capacity Range |

| Dual-Shaft Shear | High torque, handles rigid plastics | PVC pipes, electronic casings | 0.5–20 tons/hour |

| Single-Shaft Shred | Low noise, suitable for flexible materials | PE film, plastic bags | 0.2–5 tons/hour |

| Fine Granulator | Uniform particles, connects to pelletizing | Pre-shredded plastic | 1–10 tons/hour |

(Bold core conclusion) Selection Recommendations:

• For mostly rigid plastics → Choose dual-shaft;

• For mostly flexible waste → Choose single-shaft;

• For direct pelletizing → Choose fine granulator.

4. Plastic Shredder Maintenance: 5 Steps to Extend Lifespan

(Covers the long-tail keyword "plastic shredder maintenance methods")

Follow these steps to extend equipment lifespan to 8 years:

1. Pretreatment: Use a magnetic separator to remove metal impurities and avoid blade wear;

2. Feeding: Start at low speed, then increase volume once stable (add heaters for sticky plastics);

3. Weekly Inspection: Sharpen or replace blades when the gap exceeds 0.02 inches;

4. Monthly Maintenance: Lubricate the gearbox and clean the cutting chamber;

5. Semi-Annual Servicing: Replace hydraulic oil and inspect electrical circuits.

5. Frequently Asked Questions (FAQ)

(Covers the long-tail keyword "plastic shredder common questions")

1. Can plastic shredders handle mixed waste?

Yes, but dual-shaft shredders are better for mixed rigid/flexible materials; pre-sorting is recommended to avoid uneven blade wear.

2. How long can a plastic shredder run daily?

Industrial-grade units can operate continuously for 8–12 hours; it’s advised to shut down for 10 minutes every 4 hours to cool down.

3. How often should plastic shredder blades be replaced?

Depends on usage frequency: 8 hours/day → Replace every 3 months; 4 hours/day → Replace every 6 months.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment