Are you looking for how to select a scrap metal shredder? Or wondering "what’s the daily processing capacity of a steel scrap shredder" or "how to improve recovery rates with an aluminum chip shredder"?

In the recycling industry, scrap metal shredders are no longer optional equipment—they can turn messy materials like end-of-life vehicles, steel beams, and aluminum castings into uniform 50-300mm fragments. This not only reduces transportation costs by 60-80% but also separates impurities like plastic and rubber, allowing scrap metal to meet smelter procurement standards directly.

Below, we break down the core details of scrap metal shredders across 5 dimensions: principle, cases, selection, operation, and FAQs.

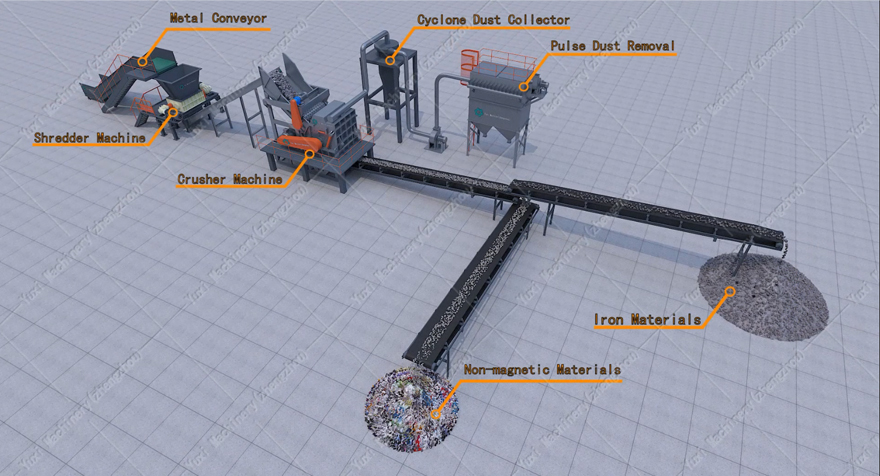

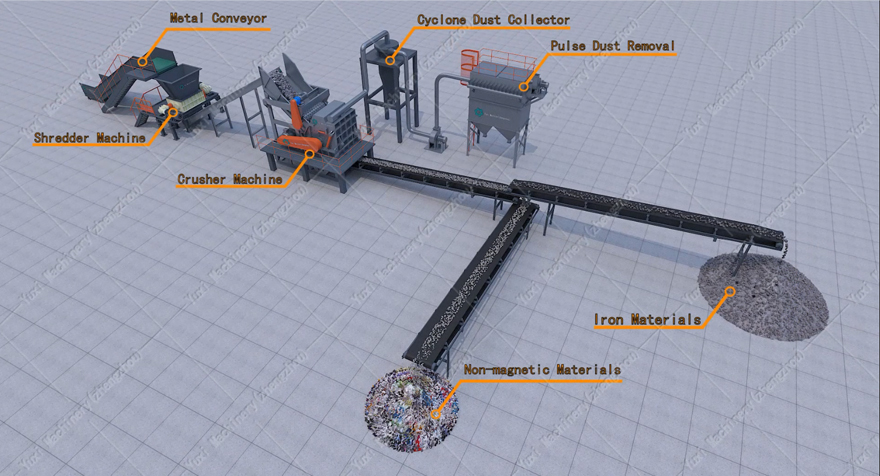

1. Scrap Metal Shredders: Understand the Core Principle in 3 Minutes

A scrap metal shredder is a heavy-duty device with high torque and low speed, using three forces—shearing, extrusion, and impact—to shape scrap metal into manageable fragments.

Key Component Functions:

1. Cutting System

◦ Material: Mn13 wear-resistant steel, D2 tool steel (hardness HRC 58-62);

◦ Type: Dual-shaft cutters (for thick/mixed materials), single-shaft cutters (for light/thin materials), hammers (for castings);

◦ Feature: Rotatable/replaceable cutter heads, with a wear life of 800-1200 hours.

2. Power System

◦ Motor: 67-1340HP three-phase asynchronous motor (for standard materials);

◦ Hydraulic system: Suitable for hard/irregular materials (e.g., cast iron), with 30% higher torque than motors.

3. Auxiliary Systems

◦ Magnetic separation unit: Synchronously separates iron impurities from fragments, achieving 99% purity;

◦ Dust collection system: Captures dust generated during shredding, with emission concentration ≤10mg/m³;

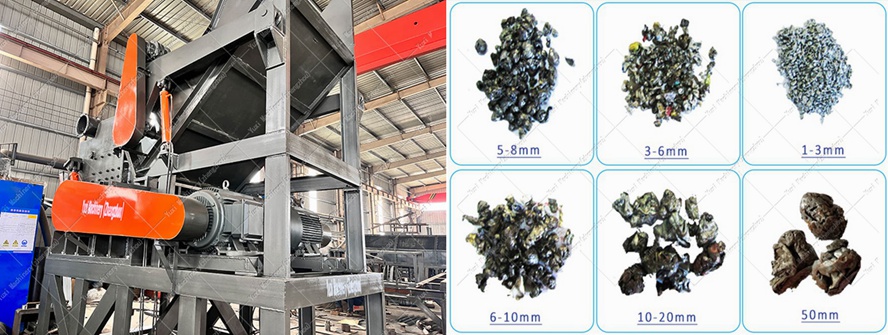

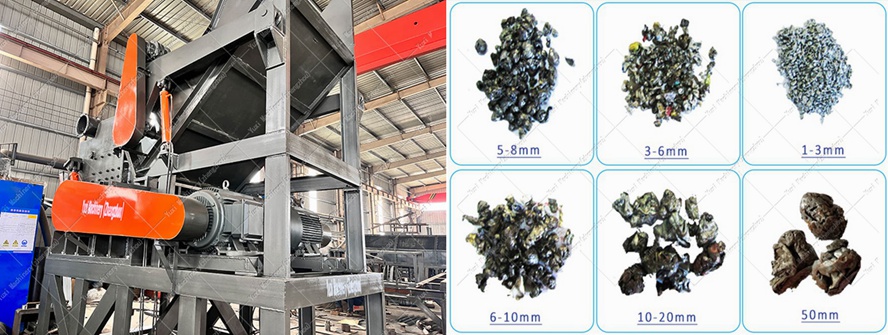

◦ Screen device: Controls output fragment size (50mm/100mm/200mm options) to match downstream smelting/sorting needs.

2. Real-World Scrap Metal Shredder Cases: 2 Industry Scenarios

Case 1: Large Recycling Plant in Henan – 5x Efficiency Boost for Steel Scrap Processing

Background: The plant recycles 3,000 tons of steel scrap monthly (including end-of-life vehicles, construction beams, and old containers). Manual dismantling + small shears only processed 15 tons/day, causing severe site congestion; transportation costs accounted for 25% of revenue.

Solution: Deployed a 1200-type dual-shaft steel scrap shredder (with magnetic separation + dust collection systems).

Results:

• Processing capacity: 80-100 tons/day, monthly output increased to 2,400 tons;

• Cost optimization: Transportation costs dropped from 25% to 8%, saving ¥1.2 million annually;

• Revenue lift: Uniform 100mm fragments fetched 12% higher prices from smelters, adding ¥960,000 in annual income;

• Labor savings: Cut 12 dismantling roles, reducing annual labor costs by ¥700,000.

Case 2: Auto Parts Factory in Germany – 11% Reduction in Aluminum Chip Loss

Background: The factory generated 5 tons of aluminum scrap monthly (defective die castings, stamping offcuts). The original "manual sorting + smelting" method caused 15% aluminum loss, and iron impurities shortened furnace lifespan.

Solution: Adopted a single-shaft aluminum chip shredder + eddy current separation system.

Results:

• Process flow: Aluminum scrap → shredded into 50mm particles → eddy current separation (aluminum/iron separation) → direct smelting;

• Recovery lift: Aluminum loss dropped from 15% to 4%, recovering 3.6 tons more primary aluminum annually;

• Equipment protection: 99.5% iron impurity removal extended furnace maintenance intervals from 3 to 6 months;

• Efficiency boost: Processing time reduced from 2 days/ton to 2 hours/ton.

3. Scrap Metal Shredder Selection: 4 Key Parameters (Avoidance Guide)

Choosing the right equipment directly impacts profitability—focus on these 4 parameters:

| Parameter | Core Criteria | Suitable Scenarios |

| Processing Capacity | Match daily scrap volume (20% redundancy recommended) | Small yards: 20-50 tons/day; Mid-sized plants: 80-150 tons/day |

| Cutter Material | Mn13 wear-resistant steel for standard materials; D2 tool steel for hard materials | D2 tool steel for steel/iron; Mn13 for aluminum/copper |

| Output Size | Align with downstream needs: 50mm for aluminum smelting; 100-200mm for steel scrap | 100mm for direct smelter sales; 200mm for secondary sorting |

| Power Configuration | Motor for light/thin materials; hydraulic system for hard/mixed materials | Hydraulic dual-shaft for end-of-life vehicles; motor single-shaft for aluminum chips |

Selection Pitfalls to Avoid:

• Don’t oversize for capacity: Excess capacity increases power consumption (100 tons/day models use ~112kW/h);

• Don’t skip auxiliary systems: Missing magnetic separation/dust collection leads to low fragment purity and non-compliant emissions.

4. Scrap Metal Shredder Operation: 5 Safety & Maintenance Tips

80% of equipment lifespan and safety depend on proper operation:

1. Pre-Startup Checks

◦ Verify cutter tightness (torque ≥221ft·lb);

◦ Inspect bearing lubrication (reapply lithium grease every 8 hours);

◦ Test emergency stop button functionality.

2. Feeding Guidelines

◦ Prohibit flammable/explosive items (e.g., gas tanks, oxygen cylinders);

◦ Bundle light materials (e.g., sheet metal) to prevent jamming;

◦ Use conveyors/robotic arms for feeding—never feed by hand.

3. In-Operation Monitoring

◦ Monitor current: Shut down to clear blockages if current exceeds 10% of rated value;

◦ Listen for abnormal noise: Unusual sounds may indicate loose cutters.

4. Post-Shutdown Maintenance

◦ Remove residual fragments to prevent rust;

◦ Inspect cutter wear weekly—grind or replace if wear exceeds 5mm.

5. Safety Protection

◦ Operators must wear hard hats and impact-resistant gloves;

◦ Install safety barriers around the equipment—no unauthorized personnel allowed.

5. Scrap Metal Shredder FAQs

Q1: What shredder is suitable for small recycling yards?

Opt for a 20-50 tons/day single-shaft shredder—benefits include:

• Low investment: ¥150,000-400,000;

• Compact footprint: ~161sq ft;

• Easy operation: 1 person can handle feeding/discharging.

Q2: How to address cutter wear?

• Routine maintenance: Rotate cutter positions every 100 hours (dual-shaft models can swap heads);

• Repair: Grind edges with a wheel if wear ≤5mm;

• Replacement: Replace heads if wear >5mm or chipping occurs (every 6-12 months).

Q3: Can painted/plastic-coated metal be shredded?

Yes. Coatings are stripped during shredding; subsequent steps:

• Dust collection system captures paint residue;

• Air separation removes plastic impurities;

Final fragment purity reaches ≥98%, meeting emission requirements.

Q4: Can shredders run 24/7?

Not recommended. Continuous operation accelerates bearing/cutter wear—follow these guidelines:

• Operate 8-12 hours daily;

• Cool down for 30 minutes every 4 hours;

• Conduct full inspections monthly to extend equipment life by 3+ years.

Q5: Dual-shaft vs. single-shaft shredders—how to choose?

| Model | Advantages | Suitable Materials |

| Dual-shaft shredder | High torque, ideal for mixed/thick materials | End-of-life vehicles, steel beams, cast iron |

| Single-shaft shredder | Low cost, ideal for light/thin materials | Aluminum chips, sheet metal, copper cables |

Conclusion

Scrap metal shredders are core efficiency tools for steel/aluminum/copper recycling—from the Henan plant’s 100-ton daily capacity to the German factory’s 11% loss reduction, choosing the right equipment + proper operation drives profitability and compliant emissions.

If you’re still unsure how to match models to your needs, a detailed parameter comparison table can simplify decision-making.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment