Driven by both resource recycling and environmental policies, cable shredders have become a core piece of equipment in the waste cable recycling industry chain. This article will present a comprehensive overview of cable shredders from multiple perspectives, including technical principles, industry applications, performance indicators, and workflow.

I. Core Technical Analysis of Cable Shredders

A cable shredder is specialized equipment designed to process waste cables. Its core technologies include:

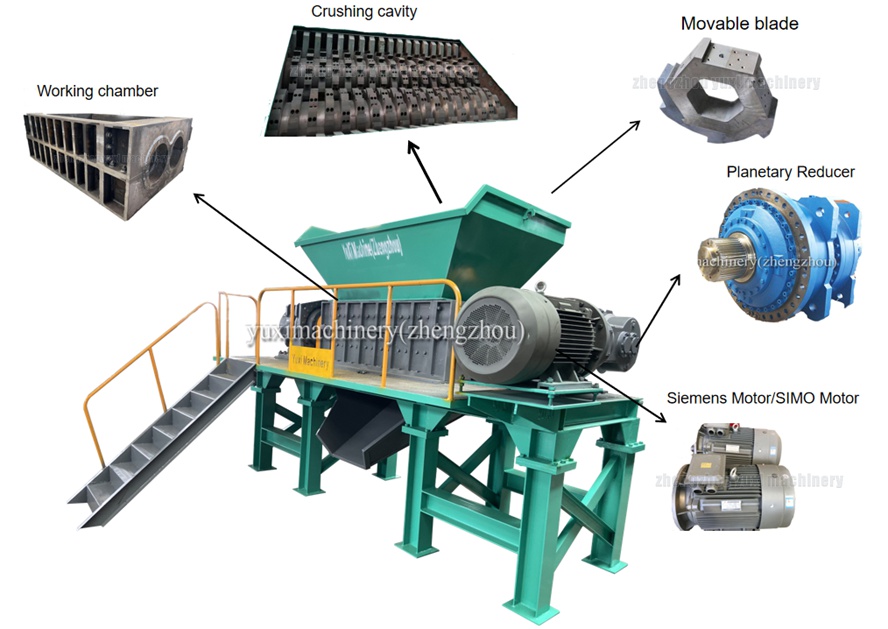

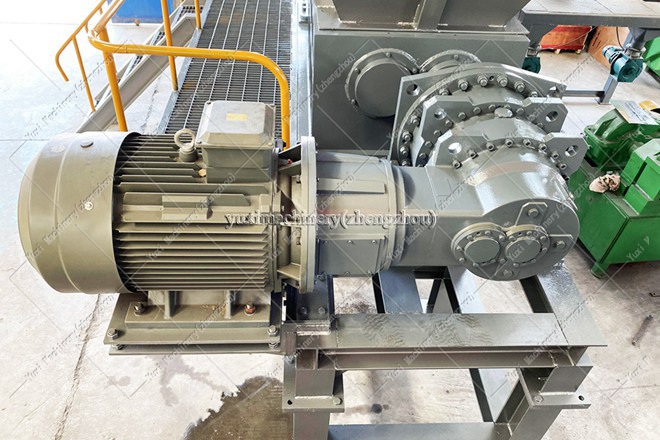

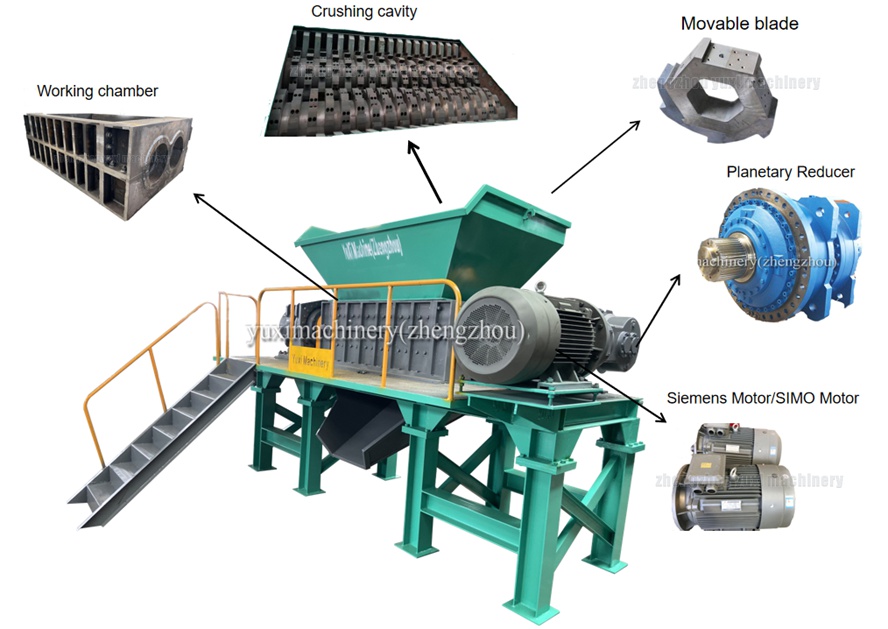

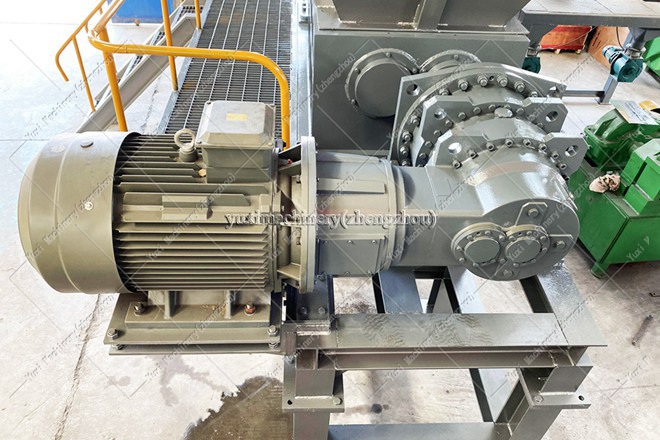

Mechanical Structure Design: Modern cable shredders typically use a dual-shaft shredding structure, with interlaced moving and fixed blades working together to efficiently shred cables. The blades are usually made of high-strength alloy steel, treated with special heat treatment processes to ensure excellent wear resistance and impact resistance.

Separation Technology: After shredding, the cable material requires effective separation of metal and plastic. Common separation methods include:

• Air separation: Utilizes density differences between metal and plastic

• Electrostatic separation: Suitable for separating fine particles

• Water separation: Effective in wet recycling processes

Automated Control System: Advanced cable shredders are equipped with PLC control systems, enabling real-time monitoring and adjustment of feeding speed, shredding force, and separation efficiency to ensure optimal performance.

Dust and Environmental Protection Technology: To meet environmental requirements, modern cable shredders are generally equipped with efficient dust removal systems to effectively control dust emissions and ensure compliance with European and American environmental standards.

II. Application Scope and Industry Cases of Cable Shredders

Cable shredders have wide-ranging applications, primarily in:

Urban Cable Recycling Projects

During the renovation of an old urban area in a major city, a large amount of waste cable was generated. By introducing advanced dual-shaft cable shredders and supporting sorting equipment, efficient separation of metal and plastic was achieved. Project data shows that the equipment can process approximately 5 tons of cable per hour, with a metal recovery rate exceeding 99%, recycling thousands of tons of copper annually.

E-Waste Processing Centers

A large e-waste processing center integrated cable shredders into its overall solution. Working in coordination with other equipment, the center achieved full-process treatment from waste electrical appliances to recycled resources, with an annual processing capacity exceeding 100,000 tons, creating significant economic and environmental benefits.

Closed-Loop Production in Cable Manufacturing

A cable manufacturing enterprise introduced cable shredders to enable immediate recycling of production scraps. This not only reduced raw material costs but also decreased waste emissions, achieving both environmental and economic benefits.

Automobile Dismantling Industry

In the automobile dismantling sector, cable shredders are used to process automotive wiring harnesses, enabling efficient copper recycling. Data from an auto dismantling plant shows that after implementing cable shredders, copper recovery rates increased by 15% while processing costs decreased by 20%.

III. Performance Indicators and Selection Guide for Cable Shredders

When selecting a cable shredder, pay special attention to these key indicators:

• Processing Capacity: Choose a suitable throughput based on actual needs to avoid equipment idleness or overload.

• Separation Efficiency: A critical performance indicator that directly impacts recycling benefits.

• Energy Consumption: Energy-efficient equipment not only reduces operating costs but also better meets European and American environmental requirements.

• Maintenance Needs: Select equipment that is easy to maintain and clean to reduce long-term operating costs.

• Safety Performance: Comprehensive safety protection systems are essential for operator safety.

• Equipment Configuration: Choose appropriate blade configurations and sorting systems based on material types and processing requirements.

IV. Workflow and Operational Specifications for Cable Shredders

Typical Workflow:

1. Raw Material Pretreatment: Initial processing of particularly large or hard cables

2. Shredding Stage: Shredding cables to appropriate sizes using dual-shaft shredders

3. Sorting Stage: Separating metal and plastic using methods like air separation and electrostatic separation

4. Post-Processing: Further processing of separated metal and plastic

5. Dust and Environmental Treatment: Controlling dust and emissions throughout the process

Operational Specifications:

• Strictly follow equipment instructions

• Conduct regular equipment inspections and maintenance

• Ensure operators receive professional training

• Establish comprehensive safety operating procedures

• Regularly perform equipment performance testing and calibration

V. Frequently Asked Questions

Q1: Can cable shredders handle all types of cables?

A: Most cable shredders can handle common power and communication cables, but special configurations or pretreatment may be needed for some special cables (e.g., high-voltage cables, armored cables).

Q2: Are the operating costs of cable shredders high?

A: Operating costs mainly include electricity, blade wear, and maintenance. Choosing energy-efficient, easy-to-maintain equipment can significantly reduce long-term operating costs.

Q3: Do cable shredding processes produce hazardous substances?

A: Modern cable shredders are typically equipped with comprehensive dust and exhaust treatment systems, effectively controlling dust and harmful gas emissions to meet European and American environmental standards.

Q4: Is installation and commissioning of cable shredders complicated?

A: Professional equipment suppliers provide complete installation, commissioning, and operator training to ensure quick startup.

Q5: What is the service life of cable shredders?

A: Service life depends on equipment quality, usage frequency, and maintenance. Generally, high-quality cable shredders can operate stably for over 10 years under normal use and maintenance.

Q6: What is the noise level of cable shredders?

A: Modern cable shredders generally use noise reduction designs, with noise levels controlled below 85 decibels, meeting European and American industrial noise standards.

Q7: Does a cable shredder require a large footprint?

A: Footprint varies by model. Small equipment can be installed in just a few dozen square meters, while large production lines may require several hundred square meters.

Conclusion

As a key piece of equipment in the cable recycling industry chain, the technical advancement and application effectiveness of cable shredders directly impact industry development. By deeply understanding their working principles, application cases, and selection points, businesses and individuals can better utilize this technology to achieve efficient resource recycling and contribute to sustainable development.

With increasingly stringent environmental policies and continuous progress in resource recycling technologies, cable shredders will play an even more important role in future resource recycling. Choosing the right equipment not only brings significant economic benefits but also contributes positively to environmental protection.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment