In modern manufacturing and recycling industries, plastic shredders play a crucial role. These powerful machines can break large plastic materials into smaller particles, paving the way for subsequent recycling, reuse, and processing.

1. Working Principle of Plastic Shredders

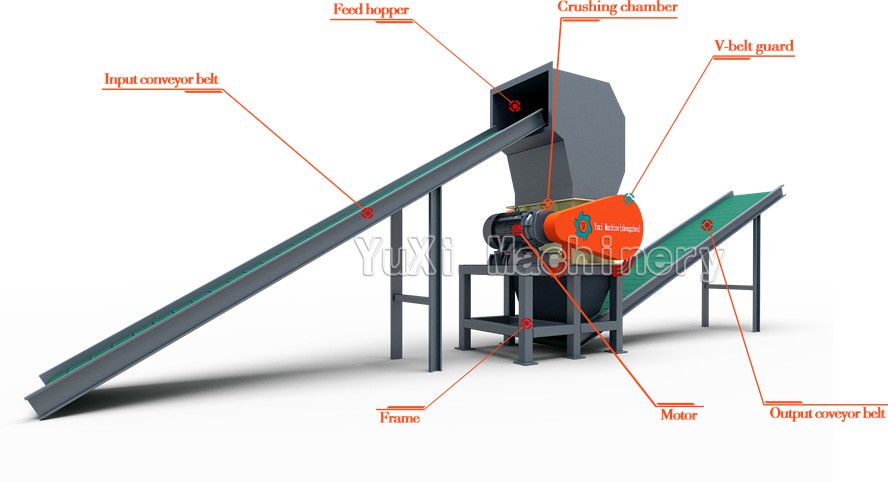

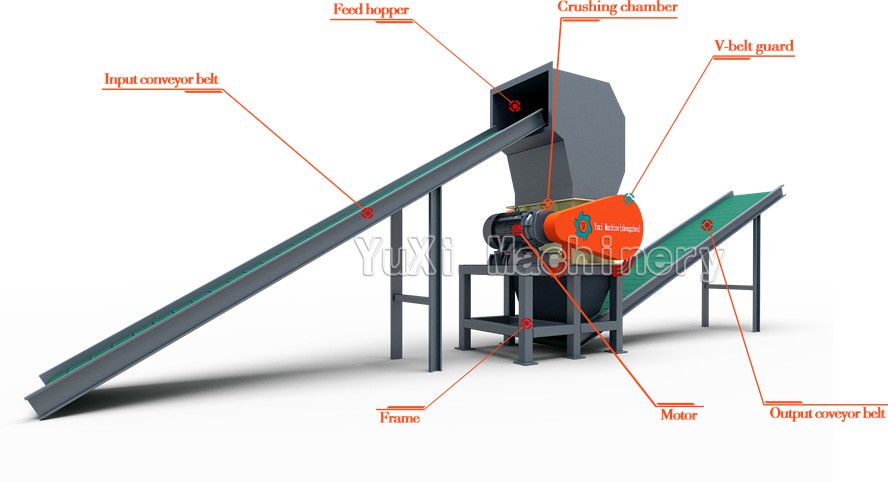

Plastic shredders use a combination of high-speed rotating blades and fixed knife holders to tear, shear, and crush plastic materials entering the crushing chamber. The core components include:

• Blade System: Typically made of high-strength alloy steel, sharp and wear-resistant.

• Screen: Controls the size of crushed particles.

• Transmission System: Provides continuous and stable power.

• Feeding System: Ensures uniform feeding of materials into the crushing chamber.

Working Process:

1. Materials enter the crushing chamber through the feed inlet.

2. High-speed rotating moving knives work with fixed knives to shear and crush materials.

3. Particles that meet the screen size pass through the screen and are discharged.

4. Particles that do not meet the size requirements continue to be crushed in the chamber.

2. Main Types of Plastic Shredders

Depending on application scenarios and material types, plastic shredders can be categorized into several types:

1. Flat Blade Shredder: Suitable for soft materials like films and fibers.

2. Claw Blade Shredder: Suitable for hard materials like injection-molded parts and thick-walled products.

3. Quiet Shredder: Designed for noise-sensitive environments.

4. Medical Waste Shredder: Complies with strict medical waste treatment standards.

5. Film Shredder: Specifically designed for processing plastic films and woven bags.

6. Pipe Shredder: Suitable for pipes made of PVC, PE, etc.

3. Application Case: PET Bottle Recycling

A large recycling center introduced a claw blade plastic shredder specifically for processing recycled PET beverage bottles. By adjusting the screen size, PET bottles are crushed into 10-20mm particles, which are then washed, dried, and ultimately used to produce recycled fibers and packaging materials. This process not only improves recycling efficiency but also reduces the demand for new raw materials.

Key features of this shredder:

• Production Capacity: 400-60,000 kg/h

• Feed Size: 500-3000 mm

• Applicable Materials: Mineral water bottles, PET bottles, oil bottles, gasoline bottles, plastic buckets, plastic pallets, plastic baskets, and other plastic products.

• Application Areas: Plastic crushing, recycling, and processing industries.

4. Selection and Maintenance of Plastic Shredders

Factors to consider when selecting a suitable plastic shredder:

• Material type and hardness.

• Expected output.

• Particle size requirements.

• Budget constraints.

• Noise and dust control requirements.

Maintenance Tips:

• Regularly check blade wear.

• Clean screen blockages.

• Keep the equipment lubricated.

• Inspect and replace worn parts.

• Regularly calibrate and adjust the equipment.

5. Latest Developments in Plastic Shredding Technology

With technological advancements, plastic shredders are continuously evolving:

• Intelligent Control Systems: Enable automated operation and real-time monitoring.

• Energy-Efficient Designs: Reduce energy consumption through optimized motors and transmission systems.

• Modular Designs: Facilitate easy maintenance and upgrades.

• Special Coatings: Enhance blade lifespan and wear resistance.

• Integrated Recycling Systems: Integrate crushing, washing, and drying processes.

6. Frequently Asked Questions

1. Can plastic shredders handle all types of plastic?

No. Different plastics (e.g., PE, PP, PET, PVC) have distinct physical properties, requiring appropriate shredder types and blade configurations. Some plastics (e.g., PVC) may release harmful gases during crushing and require special handling.

2. How to determine the appropriate screen size?

Screen size determines the final particle size. Generally, the screen size should be slightly smaller than the maximum desired particle size. For example, for 10mm particles, an 8-9mm screen is suitable.

3. How often do plastic shredder blades need replacement?

Blade lifespan depends on material type, hardness, and processing volume. Typically, blades wear faster when processing hard materials, requiring replacement every 1-3 months. For soft materials, blades can last 6-12 months.

4. How to ensure safety during plastic shredding?

Install safety guards, emergency stop buttons, and provide professional training for operators. Regular equipment inspections and maintenance are also essential to ensure safe operation.

By understanding the working principle, types, application cases, and maintenance of plastic shredders, you can more effectively select and use these critical machines, contributing to plastic recycling and reuse.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment