In the industrial layout of the circular economy for resources, cable shredders serve as core equipment for recycling waste cables. Their technical compliance and performance adaptability directly determine market competitiveness. This article analyzes the technical implementation logic of the equipment from the dimensions of power systems, material standards, environmental compliance, and application scenarios, addressing key pain points for practitioners in equipment selection and process optimization.

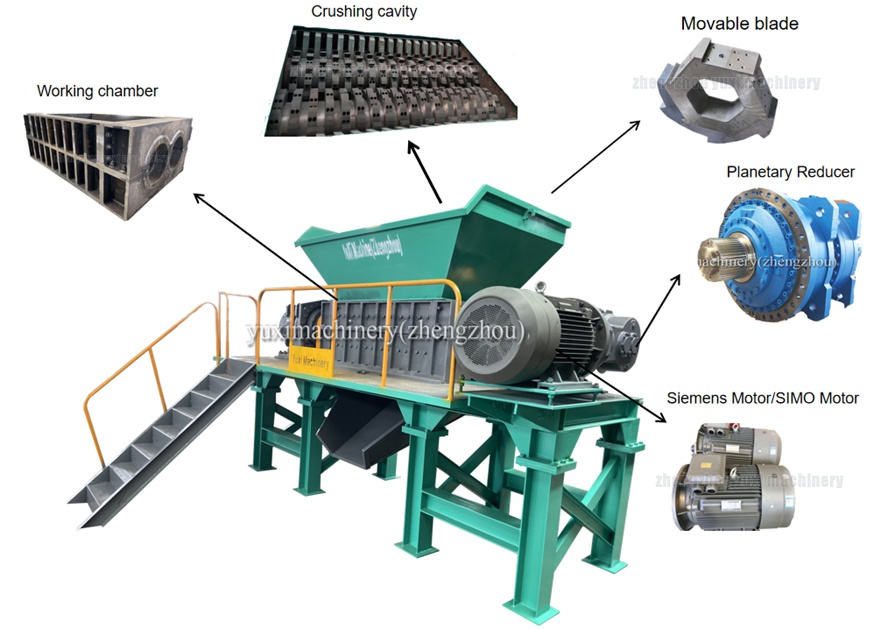

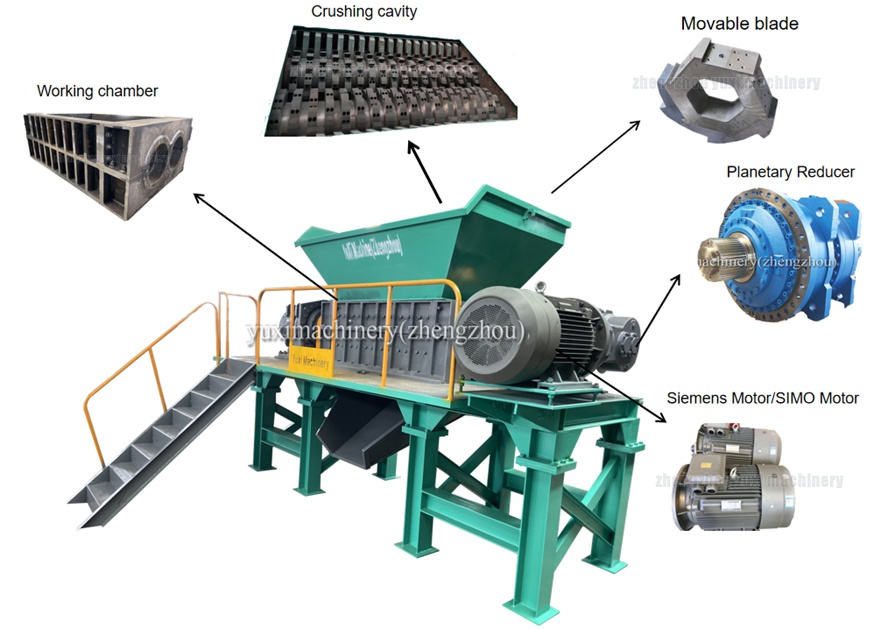

1. Power and Transmission Systems: Adaptation and Upgrade to Industrial Standards

The market has strict requirements for the energy efficiency rating and safety certification of power equipment. The power system of cable shredders must meet the following adaptation criteria:

•Motor Configuration: Adopt IE5 ultra-high efficiency permanent magnet synchronous motors, matched with planetary reducers from well-known international brands, ensuring a transmission efficiency of ≥96%. Motor power is labeled with both horsepower (HP) and kilowatts (kW); for example, a shredder with a capacity of 5 tons per hour is equipped with a 60HP (45kW) motor to meet diverse usage habits.

•Electrical Control: Equipped with certified PLC control systems (e.g., Rockwell ControlLogix series), supporting PROFINET industrial Ethernet communication for seamless integration into factory digital management systems. It also features certified emergency stop modules and safety light curtains to meet strict safety operation requirements.

2. Materials and Structure: Compliant Design to Material Standards

The market has clear standards for equipment material strength and corrosion resistance. The core structure of cable shredders must adopt the following material systems:

•Cutters and Rotors: Use high-chromium alloy (ASTM A532 Class III), treated with vacuum quenching to achieve a hardness of HRC 62-65, ensuring excellent wear resistance during long-term operation. Rotor shafts are made of alloy structural steel (AISI 4340), treated with nitriding to achieve a surface hardness of over HV 1000, maintaining structural stability when processing hard cables.

•Equipment Frame: Constructed from carbon structural steel (ASTM A36), treated with shot blasting for rust removal and coated with high-performance fluorocarbon paint (e.g., DuPont). It passes a salt spray test of ≥4000 hours, with strong corrosion resistance to adapt to the challenges of diverse climatic environments.

3. Environmental Compliance: In-depth Meeting of Ecological Regulations

The market has strict regulations on dust emissions and noise control. Cable shredders must achieve compliance through the following environmental protection technologies:

•Dust Control: Equipped with certified pulse bag filters (EN 15012 standard) with a filtration precision of ≤1μm and a dust emission concentration of ≤5mg/m³. A "negative pressure sealing system" is installed in the crushing chamber, and HEPA high-efficiency filters are used to capture escaped dust for a second time, ensuring clean operation.

•Noise Reduction: The equipment is fitted with high-grade sound insulation enclosures (ASTM E413-04 Class O), adopting a composite structure of centrifugal glass wool and damping steel plates. The operating noise is ≤75dB (measured 1 meter from the equipment), meeting strict noise control requirements.

4. Application Scenarios: Adapting to Differentiated Market Demands

1.Large-scale Processing of Decommissioned Power Cables

For the recycling of 500kV cross-linked polyethylene (XLPE) cables, a "heavy-duty crushing + superconducting magnetic separation" process is adopted. An intelligent production line with a capacity of 15 tons per hour uses "dual-rotor differential crushing technology" to crush cables to a size of ≤8mm, achieving a copper recovery rate of 99.5%. It meets strict metal recovery purity requirements, and the annual copper recovery can significantly reduce the demand for raw copper ore mining.

2.Precision Recycling of Electronic Waste

When processing waste electronic cables (e.g., mobile phone flat cables, server wire harnesses) under relevant waste electrical and electronic equipment management requirements, a "micro-crushing + air classification" process is used. The supporting micro-scale separation module can separate copper particles with a diameter of ≤0.3mm; after "electrolytic refining", the purity reaches 99.99%, meeting environmental and quality requirements for electronic raw materials and providing recycled materials for electronic manufacturing enterprises.

3.Collaborative Processing in the Auto Dismantling Industry

Adapting to auto dismantling industry standards, the equipment can process waste auto wire harnesses, rubber hoses, and other materials. Through a "cutter quick-change system" (tool change time ≤20 minutes), it switches to the "rubber crushing mode" to crush auto rubber parts into 3mm particles, while separating steel wires and copper contacts synchronously. This realizes collaborative resource utilization of "multiple materials from one vehicle", conforming to the industrial layout of the circular economy.

5. Selection Decision: Balancing Technology and Cost

1.Core Dimensions for Equipment Selection

| Processing Capacity (Daily) | Equipment Model | Power Configuration (HP/kW) | Environmental Certification | Typical Application Area |

| ≤8 tons | YX-800EU | 75/55 | CE, UL | Small recycling plants in Western Europe |

| 10-40 tons | YX-1500NA | 125/90 | EPA, OSHA | Medium-sized recycling centers in North America |

| ≥50 tons | YX-2000EU-NA | 200/150 | CE, EPA, Energy Star | Large-scale resource recycling bases |

2.Total Lifecycle Cost Optimization

•Cutter Management: Adopt "online wear monitoring + predictive maintenance". When processing XLPE cables, high-chromium alloy cutters (ASTM A532) have a service life of up to 1500 hours, 50% longer than traditional cutters, reducing spare parts procurement costs.

•Energy Efficiency Incentives: Eligible for energy efficiency incentives in relevant regions, which can shorten the equipment investment payback period to 1.2 years.

6. Precise Answers to Industry Pain Points

1.Q: How to meet material restriction requirements for equipment?

A: All equipment components in contact with materials (cutters, liners, separation rollers) use compliant materials, such as halogen-free rubber seals and low-VOC coatings. A complete Safety Data Sheet (SDS) is provided to ensure equipment meets material-related requirements.

2.Q: How to resolve grid voltage compatibility in specific regional markets?

A: The equipment is equipped with a multi-voltage adaptation system (208V/480V, 60Hz), which realizes voltage switching through an automatic transformer. It is also fitted with regionally compatible electrical interfaces for direct connection to factory power grids.

3.Q: How to ensure technical support for cross-border transportation and installation?

A: Standardized equipment packaging (ASME standard) and sea freight securing solutions are provided. Meanwhile, a multilingual technical team (English, German, French) is available to remotely guide local teams in equipment installation and commissioning, ensuring a commissioning cycle of ≤4 weeks.

7. Technological Evolution: Forward-looking Layout

In the future, cable shredders will evolve toward "carbon footprint tracing + circular economy certification". For example, blockchain technology will be used to realize the full-lifecycle carbon footprint tracing of equipment, meeting relevant carbon management requirements. At the same time, obtaining circular economy certification will enable recycled metal and plastic materials to have higher market premiums.

For practitioners in the market, a deep understanding of technical standards and compliance requirements is key to successful equipment implementation. It is recommended to prioritize manufacturers with "localized services + customized R&D" capabilities to open up market breakthroughs through technical compliance and performance adaptability.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment