Driven by the green transformation of the textile industry and circular economy policies, the textile waste shredder is a key piece of equipment in the textile waste recycling and processing chain. Its performance parameters, structural design, and process adaptability directly determine the efficiency of waste recycling and the quality of end products. This article provides an in-depth analysis of the core characteristics and technical principles of this equipment based on industry equipment technical details, and also extends to explain the synergistic application value of textile shredders.

1. Application Scenarios and Material Adaptability of Textile Waste Shredders

Textile waste covers two major sources: the industrial end (such as leftover materials from dyeing and finishing factories and garment factories) and the consumer end (such as old clothes and home textile waste), with significant differences in material characteristics:

• Industrial textile waste: Mainly composed of pure fibers or blended grey fabrics (such as polyester tows and cotton fabric scraps, with regular shapes and low impurity rates. Shredders are required to achieve "refined crushing" to meet the raw material particle size requirements of processes such as regenerated spinning.

• Consumer-end old textiles: Including old clothes, old carpets, etc., mixed with metal zippers, plastic buckles, and different material fibers (cotton, chemical fiber, silk, etc.). They need to be roughly broken down and reduced in volume by a shredder first, and then undergo deep crushing by a shredder.

The applicable fields cover garbage recycling plants, environmental protection processing companies, resource recycling enterprises, and textile recycling factories. It can handle materials such as waste布头, waste cotton spinning, old clothes, cotton velvet, chemical fiber, linen, non-woven fabric scraps, and even extend to solid waste containing textile components such as cowhide, old shoes, and quilts.

Aiming at the characteristics of textile waste such as "high toughness, multi-fiber, and impurity mixing", the equipment structure has been professionally designed:

1. Core Structural Components

• Feeding system: Equipped with a frequency conversion speed-regulating feeding device, the feeding speed can be accurately adjusted in the range of 0-500kg/h, suitable for different density wastes such as light and thin old T-shirts and thick denim, avoiding energy waste caused by "choking" or insufficient feeding.

• Crushing chamber and cutter system:

◦ The moving cutter is made of AISI D2 alloy tool steel, with a hardness of 58-62 HRC after vacuum heat treatment. The cutting edge is designed as a "serrated + stepped" type, which improves the cutting efficiency of high-toughness chemical fibers such as polyester and nylon by more than 30%.

◦ The fixed cutter and the moving cutter form a "shearing + tearing" composite action. The inner wall of the chamber is lined with AR400 wear-resistant steel plate (thickness ≥ 12mm) to resist the impact wear of metal debris and hard buttons.

• Screening and discharging system: Built-in quick-release screen, the aperture range can be selected from 5-50mm (for example, ≤10mm is required for regenerated spinning, and the screen specification can be relaxed to 20-30mm for RDF fuel production), and the screen can be replaced within 3 minutes.

• Power transmission system: Equipped with IE4 series ultra-high efficiency motors (power coverage 20-125 HP), matched with hard-tooth surface reducers (transmission ratio i=20-50:1). Some models are equipped with hydraulic automatic tensioning devices to real-time compensate for the transmission efficiency loss caused by belt wear.

2. Crushing Process Principle

After the textile waste enters the crushing chamber, it undergoes three stages to achieve efficient crushing:

• Pre-shearing stage: After the large pieces of waste are pressed into the feeding roller, the high-speed rotating moving cutter and fixed cutter first tear them into fiber clusters.

• Deep crushing stage: Under the action of centrifugal force, the fiber clusters collide with the wear-resistant lining plate, and at the same time are repeatedly "sheared and torn" by the moving cutter and subsequent cutter groups, and the high-toughness fibers are cut into short fiber segments.

• Particle size shaping stage: The crushed materials that meet the screen aperture are discharged from the bottom, and the materials that do not meet the requirements circulate and crush in the chamber until they meet the particle size requirements.

3. Synergistic Value and Technical Differences of Textile Shredders

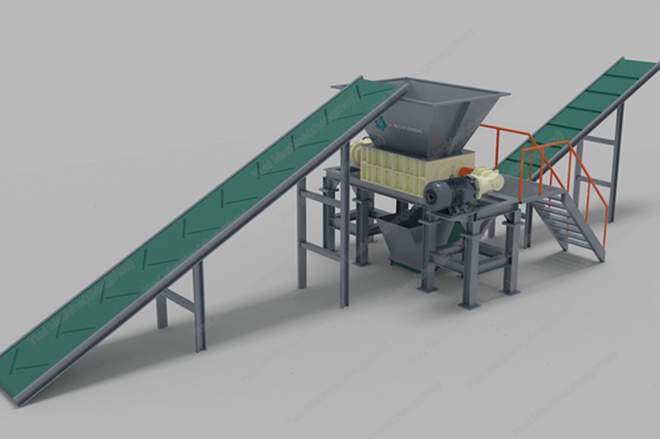

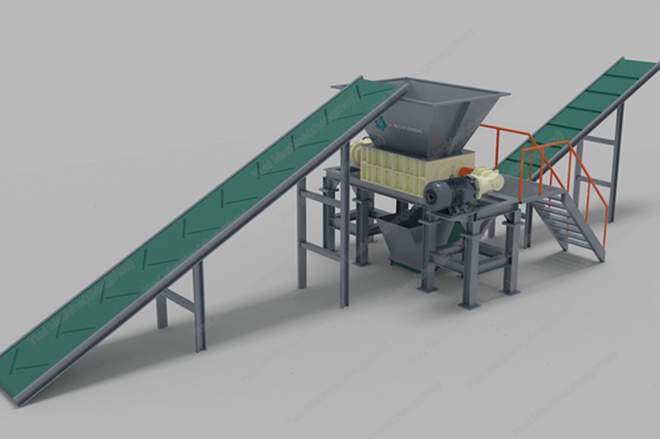

In the pretreatment stage of textile waste, the textile shredder serves as a "rough crushing" equipment, forming a "shred first and then crush" process combination with the shredder:

1. Core Design of Shredders

• Cutter system: Adopts double-shaft or four-shaft shredding cutter rollers, and the distance between the cutter rollers can be adjusted (50-200mm), suitable for textiles of different thicknesses such as thin yarn and thick canvas; the cutters are strengthened by Stellite alloy surfacing process, and the wear resistance is improved by 2 times, which can shred old clothes with metal accessories, and the discharge particle size is controlled at 100-300mm.

• Overload protection: Equipped with a hydraulic unloading system, which automatically shuts down when shredding ultra-hard debris (such as hidden metal components) to protect the core components.

• Anti-winding design: The feeding roller has a toothed structure to avoid winding and blocking of fibrous materials at the feeding port.

2. Process Connection with Shredders

The rough crushed discharge (100-300mm) of the shredder exactly matches the feeding requirements of the shredder, and the combination of the two can increase the production capacity of the entire crushing line by more than 40%:

• For old clothes with high impurity rates, first remove large pieces of impurities and reduce the volume through the shredder, which can reduce the wear rate of the shredder.

• For pure industrial textile waste, if the size is small, it can be directly fed into the shredder, but matching with a shredder can realize "flexible feeding" and stabilize the production capacity and discharge particle size uniformity of the shredder.

4. Technical Parameters and Selection Points of Textile Waste Shredders

Taking the mainstream YXS series in the industry as an example, the core parameters need to be paid attention to:

| Model | Power (HP) | Processing Capacity | Discharge Particle Size (inch) | Hopper Size (ft) | Equipment Weight (ton) | Overall Dimensions (ft) |

| YXS-600 | 40×2 | 2-3 ton/hour | 1.2-4 | 2.7×3 | 2.5 | 8.5×6.5×6.2 |

| YXS-800 | 60×2 | 3-5 ton/hour | 1.2-4 | 3×3.3 | 3.6 | 9.2×6.5×6.2 |

| YXS-1000 | 100×2 | 5-8 ton/hour | 1.2-4 | 4×3.3 | 5.7 | 9.8×6.5×6.2 |

| YXS-1400 | 150×2 | 8-12 ton/hour | 1.2-4 | 6.6×6.6 | 18 | 14.1×6.5×7.9 |

| YXS-2600 | 430×2 | 25-60 ton/hour | 1.2-4 | 10.5×6.6 | 85 | 26.9×13.1×14.1 |

Key Selection Dimensions

• Processing scale: Small recycling points can choose YXS-600/800 (processing capacity 2-8 ton/hour), and large-scale recycling factories need models above YXS-1400.

• Material characteristics: Old clothes with high impurity rates need to be matched with shredders, and pure industrial waste can be directly selected with shredders.

• Downstream processes: Regenerated spinning requires a screen aperture ≤ 4 inches, and the screen specification can be relaxed for RDF fuel production.

• Operation and maintenance costs: Pay attention to the service life guarantee of the moving cutter and fixed cutter (service life ≥ 8000 hours when processing pure textile waste), and the purchasing convenience of wearing parts.

5. Core Advantages and Industrial Value of the Equipment

The design of the textile waste shredder is fully adapted to the crushing needs of textile solid waste:

1. Material adaptability: The cutter and cavity are optimized for soft textile materials, which can efficiently crush different fiber materials such as cotton and chemical fiber, meeting the production needs of energy saving and durability.

2. Production capacity and stability: Strong crushing capacity, high output, the frame is constructed with rectangular pipes, and the main bearing uses European and American brand models, which can withstand greater impact force and ensure long-term stable operation.

3. Durability design: The crushing chamber is connected with high-strength steel plates and undergoes heat treatment. The service life of wear-resistant parts is much longer than the industry average, reducing long-term operation and maintenance costs.

4. Environmental and economic value: Convert textile waste into recycled raw materials, replace virgin fibers or be used as RDF fuel, helping enterprises achieve the dual goals of "cost reduction + environmental protection".

6. Frequently Asked Questions (FAQ)

1. Can wet textile waste be processed?

Yes, but the moisture content should be ≤ 30% (excessive moisture will cause fiber agglomeration and block the screen). Some models can be equipped with a hot air drying crushing chamber (drying temperature ≤ 120℃) to avoid chemical fiber melting while reducing the moisture content of the material.

2. What is the difference from ordinary plastic shredders?

The cutters of textile waste shredders are sharper and the distance between them is narrower, and the feeding system is added with an anti-winding design; while the cutters of plastic shredders are thicker, designed for "extrusion-tearing" of hard plastics, and are prone to fiber slipping and low crushing efficiency when processing textile waste.

3. Is a shredder required for small-batch recycling?

If the waste is bundled old clothes or large-sized rolls, it needs to be roughly broken by a shredder first; if it is small-batch and small-sized pure textile leftover materials, it can be directly used with a shredder, but matching with a shredder can improve the feeding stability and production capacity.

The technological iteration of textile waste shredders is moving towards the direction of "intelligence and customization", supporting equipment customization (such as special screen aperture, feeding method adaptation) to meet the personalized needs of different scenarios. If you need to further understand the technical details or customization plan of a certain model, you can consult the equipment manufacturer at any time for professional support.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment