Against the backdrop of global resource recycling and environmental protection, the scrap metal shredder has become a key piece of equipment in the metal recycling industry chain. With its ability to efficiently crush, reduce the volume of, and recycle scrap metal, it is a core technological tool in the metal recycling and processing sector. This article will provide an in-depth analysis of the professional details and key points of this equipment from the perspectives of technical principles, core structure, performance parameters, application scenarios, and industry value.

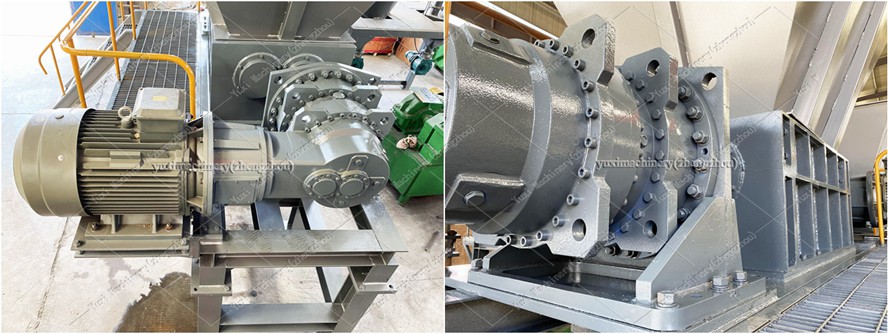

1. Technical Principles: The "Mechanical Art" of Dual-Shaft Shearing

Scrap metal shredders (especially dual-shaft types) adopt the working principle of independent dual-shaft drive + low-speed, high-torque shearing. Two knife shafts, driven by motors and reducers, rotate relative to each other to squeeze, tear, and shear the scrap metal entering the crushing chamber. This "dual-shaft intermeshing" structural design forces the material to be crushed during the process. Even high-toughness and high-viscosity metal materials can avoid equipment "jamming" under the action of low-speed and high torque, achieving continuous and efficient crushing.

From a mechanical perspective, the spiral arrangement of the cutters and the hexagonal inner hole spindle design are key: the spiral arrangement ensures that the cutters cut the material "without dead ends", improving crushing efficiency; the hexagonal design makes the cutters bear force evenly, greatly extending their service life. This is also the core technical logic that enables it to handle complex materials such as car shells and metal barrels.

2. Core Structure: The "Industrial Ingenuity" of Material and Design

1. Cutter System

The cutters are forged from AISI H13 special alloy steel (or M2 high-speed steel) through special processes, featuring good wear resistance, high strength, and repairability. This material selection allows the cutters to resist severe wear when frequently contacting metal materials; the "repairable" feature reduces equipment operation and maintenance costs—worn cutters can be reused through processes such as welding and grinding.

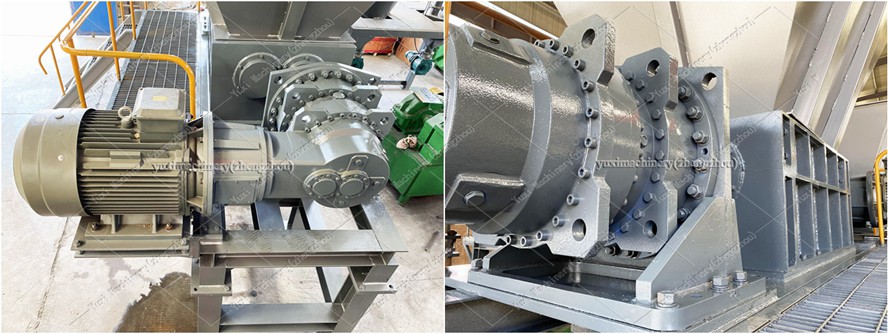

2. Bearings and Seals

The bearings adopt a six-layer sealing structure, which can effectively prevent water and dust from entering the bearing interior, extending the bearing service life by more than 30%. This is crucial for equipment that operates in harsh working conditions for a long time.

3. Control System

Mainstream equipment is equipped with a PLC automatic control system, which has functions such as start, stop, reverse rotation, and automatic reverse rotation in case of overload. When the equipment is "jammed" due to material overload, the system can automatically reverse to discharge the material, protecting the equipment while achieving unattended operation, which meets the intelligent needs of modern industry.

4. Box Structure

Adopting a split box design, the entire knife shaft assembly (including the knife shaft, blades, bearings, and sealing system) can be quickly disassembled, greatly reducing the time for equipment maintenance and knife replacement, and improving the continuous operation efficiency of the production line.

3. Performance Parameters: The "Capability Benchmark" of Industrial Grade

• Feeding Size: Ranging from 4" to 120", it can directly handle full-size scrap metal from small metal cans to car frames;

• Production Capacity: 0.44-66 tons/h (or 25-60 tons/h, depending on the model), and large equipment (such as the 2600 model) can meet the production capacity needs of large-scale recycling enterprises;

• Applicable Materials: Metal barrels, color steel tiles, car shells, frames, aluminum plates, decorative iron, waste tires, oil filters, engine casings, etc., covering almost all scrap metal and some metal-containing composite materials;

• Environmental Performance: The crushing process has noise lower than 85dB and meets EPA emission standards. The crushed metal chips are easy to transport and subsequently incinerated and smelted for recycling, reducing the occupation of scrap metal on the environment from the source.

4. Application Scenarios: The "All-Rounder" of Resource Recycling

1. Automobile Dismantling Industry

It crushes components such as the shells, frames, and engine casings of waste cars, reducing the volume of the originally bulky car wreckage, facilitating the sorting and recycling of precious metals (such as copper and aluminum), and reducing transportation costs.

2. Processing of Metal Processing Waste

It processes scraps, waste aluminum sheets, waste steel, etc. generated by metal processing plants, and recycles them after crushing, realizing the cycle of "waste → raw material" and improving the utilization rate of raw materials.

3. Daily Scrap Metal Recycling

For civilian scrap metals such as cans, metal cans, and paint buckets, crushing increases their density, facilitating centralized transportation to smelters, which is an important link in the construction of "zero waste" cities.

5. Industry Value: The "Win-Win Engine" of Environmental Protection and Economy

From an environmental perspective, scrap metal shredders greatly reduce the occupation of scrap metal on landfills and reduce the risk of heavy metal pollution through volume reduction and resource utilization; from an economic perspective, the crushed metal chips have higher recycling value (such as improved purity and reduced transportation costs), creating considerable economic benefits for recycling enterprises. Under the background of the "dual carbon" goal, as a key equipment for resource recycling, its market demand is growing continuously.

Q&A Session (with Answers)

1. What are the core advantages of the dual-shaft structure of scrap metal shredders compared to the single-shaft structure?

Answer: The dual-shaft structure adopts independent dual-shaft drive, which can achieve low-speed and high-torque shearing, and has stronger crushing ability for high-toughness and high-viscosity metal materials, and is not easy to jam; at the same time, the crushing method of dual-shaft intermeshing makes the material crushing more uniform and efficient.

2. What impact does the "repairability" of the cutter have on the life-cycle cost of the equipment?

Answer: The repairability of the cutter greatly reduces the operation and maintenance cost of the equipment. Worn cutters do not need to be replaced as a whole, and can be reused through methods such as welding and grinding, reducing the cost of spare parts procurement and equipment downtime for knife replacement, and improving the economy of the equipment throughout its life cycle.

3. Please analyze the specific value of the PLC control system in the operation and maintenance of scrap metal shredders.

Answer: The PLC control system realizes the automatic control of the equipment, with functions such as start, stop, reverse rotation, and automatic reverse rotation in case of overload. It can effectively avoid equipment damage caused by material overload, realize unattended operation, and improve the stability and operation and maintenance efficiency of equipment operation.

4. Combining application scenarios, explain how scrap metal shredders help the development of "urban minerals".

Answer: In the urban scrap metal recycling scenario, scrap metal shredders can crush and reduce the volume of urban "mineral" resources such as cans and car wreckage, facilitating centralized transportation and sorting, improving the recovery rate of metal resources, helping the recycling of urban resources, and promoting the large-scale and efficient development of "urban minerals".

As a key equipment for resource recycling and environmental protection, the scrap metal shredder, with its professional dual-shaft shearing technology, ingenious structural design, and wide range of application scenarios, has become the core driving force of the metal recycling industry. It not only realizes the efficient deconstruction and resource utilization of scrap metal, but also creates dual environmental and economic values for enterprises in the "dual carbon" era. Whether from the perspective of technical depth, industry value, or social significance, the scrap metal shredder is a well-deserved "metal deconstruction expert" in the field of resource recycling, and its development and application will continue to promote the process of global metal resource recycling.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment