In the face of infectious and injurious waste generated from medical activities, the medical waste shredder is a key line of defense for protecting public health and the environment. Through efficient shredding and volume reduction, it transforms medical waste from a potential "health threat" into material that can be disposed of in a standardized manner, laying a solid foundation for the harmless and resourceful treatment of medical waste.

1. Application Value and Real-World Case of Medical Waste Shredders

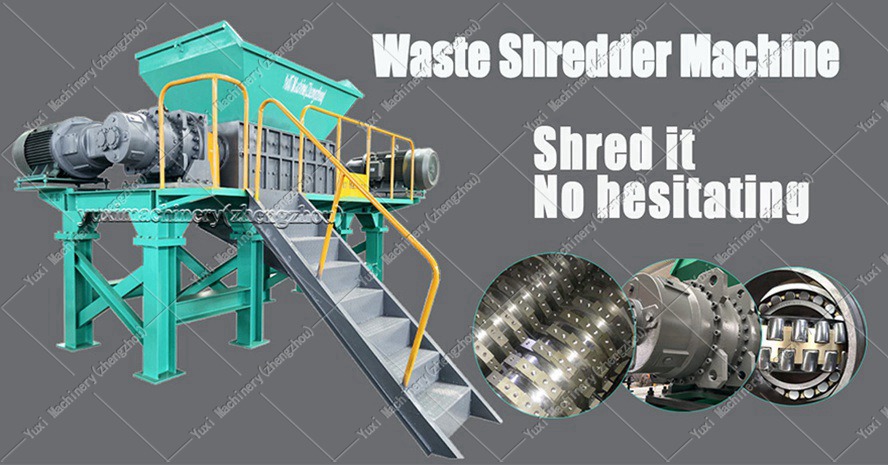

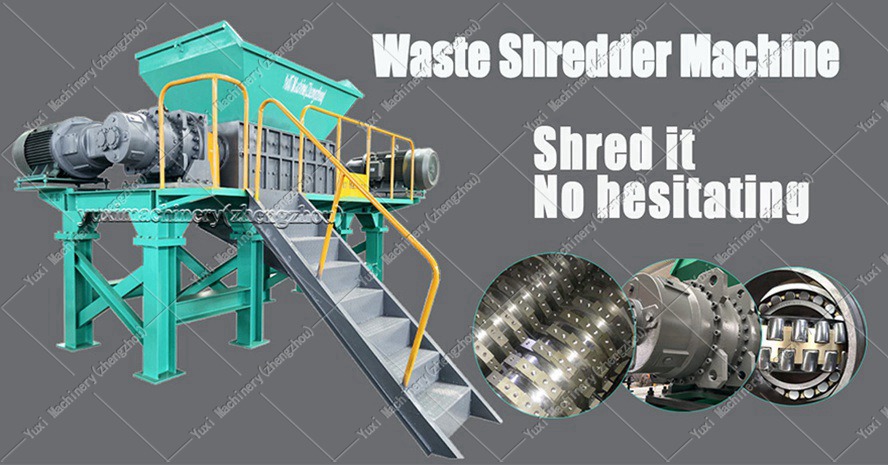

Medical waste such as infectious dressings, discarded syringes, and expired drugs can easily cause germ transmission and environmental pollution if not properly disposed of. Medical waste shredders, through the shredding process, achieve the connection between medical waste volume reduction and subsequent safe disposal.

Take a medical waste treatment center in New York, USA as an example. After introducing a dual-shaft medical waste shredder, its processing efficiency has been significantly improved. Previously, the center needed to manually dismantle large medical waste (such as discarded hospital beds and large equipment casings), which was not only time-consuming (it took 2-3 hours to dismantle a single piece of equipment) but also resulted in unevenly shredded particles, making subsequent disinfection and disposal difficult. After introducing the shredder, medical waste is shredded to a particle size of no more than 2 inches, with a volume reduction rate of more than 70%. The efficiency of subsequent high-temperature sterilization and other disposal processes has increased by 40%, and it can safely dispose of more than 10,000 tons of medical waste every year, effectively reducing the infection risk of medical waste in transportation and storage.

2. Core Advantages of Medical Waste Shredders

(1) Wide Shredding Range and Significant Volume Reduction Effect

It can handle various types of medical waste such as small medical devices, infectious dressings, expired drugs, discarded syringes, and disposable protective equipment. Whether it is hard metal needles or tough plastic infusion bags, it can efficiently shred them to achieve a significant volume reduction.

(2) Outstanding Safety and Environmental Performance

The equipment adopts a sealed design. Aerosols generated during the shredding process are collected and disinfected under negative pressure, with a dust emission concentration of less than 0.01 grams per cubic meter and noise controlled within 80 decibels. At the same time, the cutters are made of cemented carbide, which is wear-resistant and corrosion-resistant, meeting the shredding requirements of highly mixed medical waste and ensuring uniform and controllable particle size of the discharged material.

3. Common Q&A about Medical Waste Shredding

Q: How to ensure the harmlessness of medical waste after shredding?

A: The methods of "shredding first and then sterilization" or "shredding and sterilization simultaneously" are usually adopted. The shredded medical waste undergoes processes such as high-temperature incineration, chemical disinfection, or high-temperature steam sterilization to completely eliminate germs and toxicity.

Q: What are the key points for the maintenance of medical waste shredders?

A: Check the tightness of bolts, the operating status of sensors and motors every week; check the wear of cutters every month; conduct a comprehensive overhaul every year, including dismantling and cleaning the motor, reducer, and cleaning the waste lubricating oil to ensure the stable operation of the equipment.

The medical waste shredder is a key converter of medical waste from a "hazard source" to "disposable material". With its precise shredding capability, it opens an efficient channel for the harmless and resourceful disposal of medical waste. It plays an indispensable role as a "safety guardian" in the battle to protect public health and the ecological environment, continuously empowering the green development of the medical industry.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment