With the rapid development of the medical industry, the standardized and harmless treatment of medical waste has become a key link in ensuring public health and the ecological environment. The medical waste shredder, as the core equipment for the pretreatment of medical waste, lays a solid foundation for subsequent sterilization and disposal processes with its efficient crushing capacity for various medical wastes. This article will deeply analyze the professional details of medical waste shredders from the dimensions of equipment principles, application scenarios, technical advantages, and maintenance points.

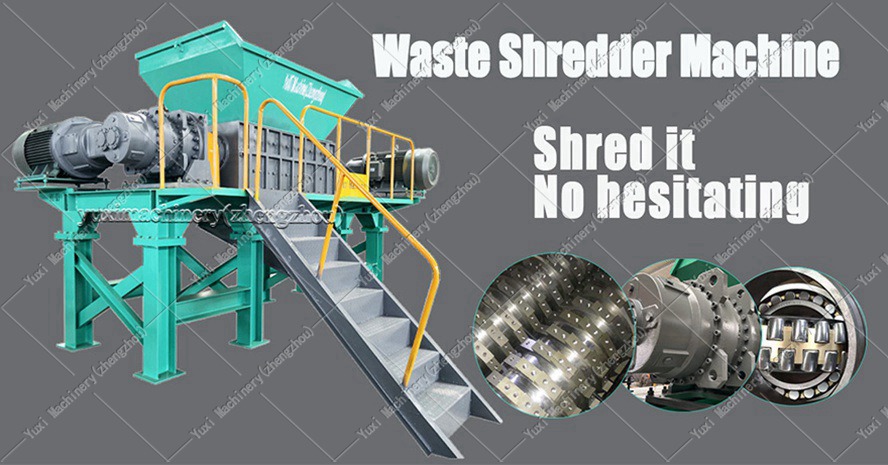

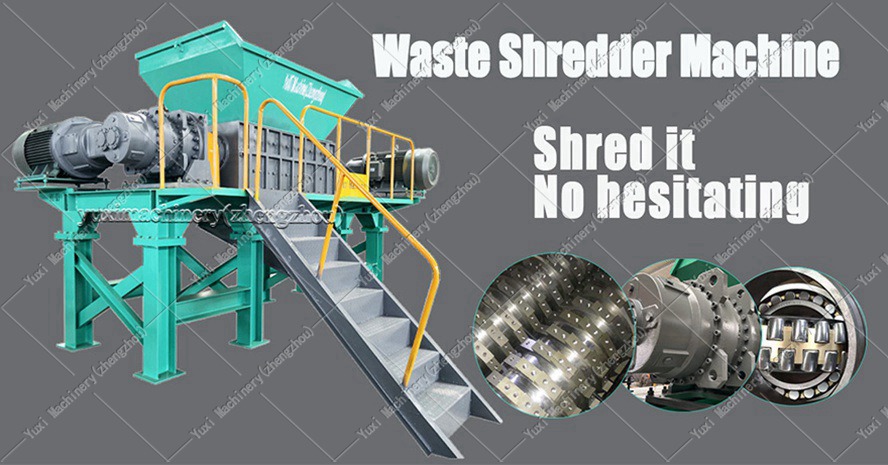

1. Equipment Principles and Technical Architecture

Medical waste shredders mainly adopt dual-shaft shredding technology, which cuts, tears, and crushes medical waste through cemented carbide cutters on two relatively rotating cutter shafts. Its core technical architecture includes:

• Power System: Driven by high-performance motors and equipped with precision reducers, the motor power can reach 15-55HP, ensuring stable torque output of the cutter shafts to meet the crushing requirements of hard and tough medical waste.

• Cutter Components: Cutters of small shredders are made of cemented carbide, complying with ASTM B777 standards, which have both high wear resistance and impact strength; large-scale equipment achieves multi-stage processing of "shredding—crushing—refining" by optimizing the arrangement of cutters, and the discharge particle size is controlled within 20-50mm.

• Sealing System: Large-scale medical waste shredders adopt high-airtightness sealing structures, complying with EPA Method 201A standards, with excellent corrosion resistance, which can effectively prevent the leakage of harmful aerosols and waste liquids generated during the crushing of medical waste and ensure the safety of the operating environment.

2. Application Scenarios and Material Processing Capacity

Medical waste shredders can efficiently process the following typical materials for the diversity of medical waste:

1. Conventional Medical Waste: Including small medical devices (such as needles, catheters), clinical waste (infectious dressings), expired drugs, etc. After crushing, the load of subsequent sterilization equipment can be reduced, and the processing capacity can reach 500-2000kg/h.

2. High-Risk Waste: Infectious waste (such as COVID-19 medical waste), various plastic wastes (infusion bottles, medicine boxes), latex materials (gloves, rubber tubes), syringe waste, etc. Through crushing, "volume reduction + homogenization" is achieved, and the volume reduction rate can reach more than 80%, improving the disinfection effect.

3. Special Medical Waste: Prosthetics, rags, blood-stained cotton yarn, disposable bed sheets, masks, protective clothing, etc. These materials are often large in volume and tough. Shredders can quickly crush them into small particles through high-torque shredding mechanisms, with particle sizes controlled within 30mm, facilitating subsequent incineration or sanitary landfill.

3. Technical Advantages and Industry Value

Compared with traditional crushing equipment, medical waste shredders have the following core advantages:

• Energy Consumption and Efficiency: When processing medical waste, the energy consumption is as low as 0.5-1.2kWh/kg, with high production efficiency, and can operate continuously for 24 hours, meeting the large-scale processing needs of medical institutions and medical waste centralized disposal centers, with an annual processing capacity of 5000-20000 tons.

• Material Adaptability: Suitable for crushing various large-volume, tough and difficult-to-crush materials (such as stainless steel medical devices, prosthetics), complying with ANSI/ASME B30.15 standards, solving the pain points of "material jamming and fast wear" of traditional equipment.

• Process Compatibility: Seamlessly connected with subsequent processes such as pressure steam sterilization, chemical disinfection, and dry heat crushing sterilization. Through the coordinated process of "crushing—sterilization", the harmless treatment efficiency of medical waste is greatly improved, and the sterilization qualification rate reaches 99.99%.

4. Maintenance and Compliance Operation Points

To ensure the long-term stable operation of medical waste shredders, the following maintenance specifications should be followed:

• Weekly Inspection: Focus on checking whether each bolt and nut is loose, whether the sensor leads are damaged, and whether the operating noise and temperature of the reducer and motor are normal. The vibration value is controlled within 0.3-0.8mm/s, and mechanical failure hidden dangers are eliminated in time.

• Monthly Inspection: Conduct a comprehensive inspection of the wear of cutters and cutter shafts at least once a month. The wear amount does not exceed 0.5mm/month. Adjust the cutter gap or replace the cutters according to the wear degree to ensure the stability of the crushing particle size.

• Annual Overhaul: Conduct full disassembly and maintenance of the equipment, disassemble and clean the motor, reducer, and crushing roller bearings, clean the waste lubricating oil in the machine, and calibrate the airtightness of the sealing system. The leakage rate is less than 5ppm to ensure that the equipment performance is in the best state.

5. Industry Q&A Session

1. Why is cemented carbide chosen for the cutter material of medical waste shredders?

Answer: Cemented carbide has the characteristics of high hardness and high wear resistance, complying with ASTM B777 standards. It can reduce cutter wear during long-term crushing of medical waste (especially hard plastics and metal devices). At the same time, its impact strength can cope with the tearing of tough materials (such as latex gloves), ensuring the stability of continuous operation of the equipment. The service life of the cutter can reach 8000-12000 hours.

2. How does the medical waste shredder prevent secondary pollution when processing infectious waste?

Answer: The equipment adopts a high-airtightness sealing structure complying with EPA Method 201A standards to block the leakage of harmful substances. At the same time, the "refinement and homogenization" during the crushing process can improve the effect of subsequent disinfection processes, with a volume reduction rate of more than 80%. It avoids secondary pollution from the two dimensions of "physical isolation + process synergy", and the concentration of harmful substance emissions is lower than the limit of the EU Ecodesign standard.

3. What is the relationship between this equipment and the environmental regulations for medical waste disposal?

Answer: It complies with the requirement that "medical waste should be crushed and refined before processing". Through standardized crushing processes, it helps enterprises meet the environmental protection department's regulatory standards for "reduction, harmlessness, and resource utilization" of medical waste, with a compliance rate of 100%.

As a key equipment in the medical waste treatment industry chain, the technological iteration and application promotion of medical waste shredders will continue to promote the development of the medical waste disposal industry in the direction of "efficiency, safety, and compliance". Choosing a suitable medical waste shredder is an important measure for medical institutions and disposal centers to achieve "cost reduction and efficiency increase + environmental compliance".

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment