Metal shredders are widely used in major waste recycling stations to crush recycled color steel tiles, thin iron sheets, scrap iron scraps, pop cans, paint buckets, etc. If the to-be-shredded material has a large block size, the impact load on the blade is also large. Therefore, blades made of alloyed high-strength high-manganese steel should be selected. Its high wear resistance is guaranteed. For small and medium-sized blades, high manganese steel cannot exert its work-hardening characteristics and is not wear-resistant, high-medium carbon low-alloy steel and medium-alloy steel should be selected.

The main function of the metal shredding machine in daily work is to quickly crush waste materials, such as: steel shavings crushing, pop cans crushing, aluminum scrap crushing, automobile crushing, scrap steel crushing, etc. A series of crushed scrap metals are reused and smelted and made into new metal material. The transportation and storage of waste metal is inconvenient and high-cost. The emergence of metal crushers solves this problem. It can not only crush small metal objects such as cans, but also crush bicycles, motorcycles, cars, etc., with high crushing efficiency, low noise, uniform metal particles after crushing, good color and luster.

Yuxi Metal Shredders Have the Following Advantages:

1. Power distribution box: The transmission gear has been forged and high-frequency quenched, so it has a high service life.

2. Fixed blade: The fixed knife acts as a material guider and can prevent the material from being brought back after being broken.

3. Fixed blade holder: fix the fixed blade, optimize the maintenance and replacement of blades.

4. Sealing: The unique sealing structure can completely protect the machine even when handling materials with liquid.

5. Bearing seat: The bearing seat adopts a split type, so the cutter shaft, blade, sealing system, bearing, and other components can be removed quickly and maintained and replaced easily.

6. Moving blade: after multiple heat treatments, the inner and outer hardness and toughness of the blade material are the same, with high strength and service life. The blades can be used repeatedly.

7. Cutter shaft: The high-strength material is used to mill the hexagonal shape after high-frequency treatment after quenching and tempering, so as to fit the force of the cutter to avoid damage.

8. The feeding hopper and frame can be reasonably designed according to customer requirements.

Pay Attention to the Shredding of Bulky Materials

If the large material is crushed, it will be easy to clog, so we can remove the screen. In this case, it doesn’t matter even if feeding and shredding bulky material. If the screen is removed, there is no requirement for the water content of the material, and it will not jam when crushing bulky material. The blade and the liner are the vulnerable parts of the whole metal shredding equipment that are easy to wear, so we use high alloy to make the blade. In this way, so the blade of the shredder is more wear-resistant and not easy to be worn. Even if it is worn, blade can be used again after adjusting its position, which increases the service life of the shredder. In short, the normal operation of the blade should be ensured when the shredder is shredding large material.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

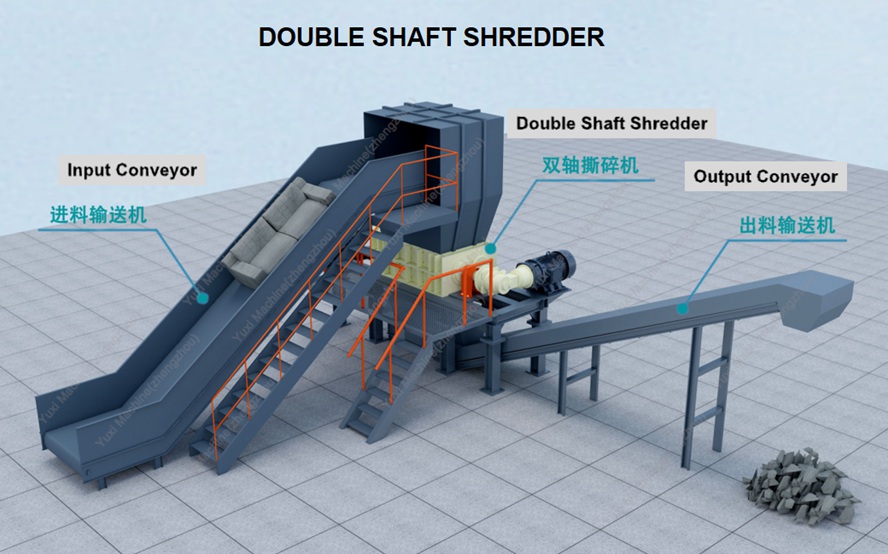

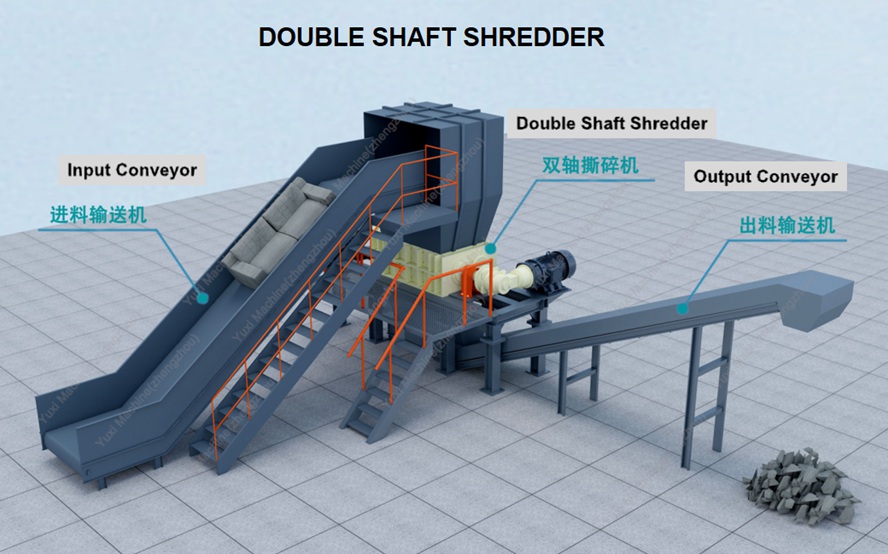

Optional Equipment

Optional Equipment