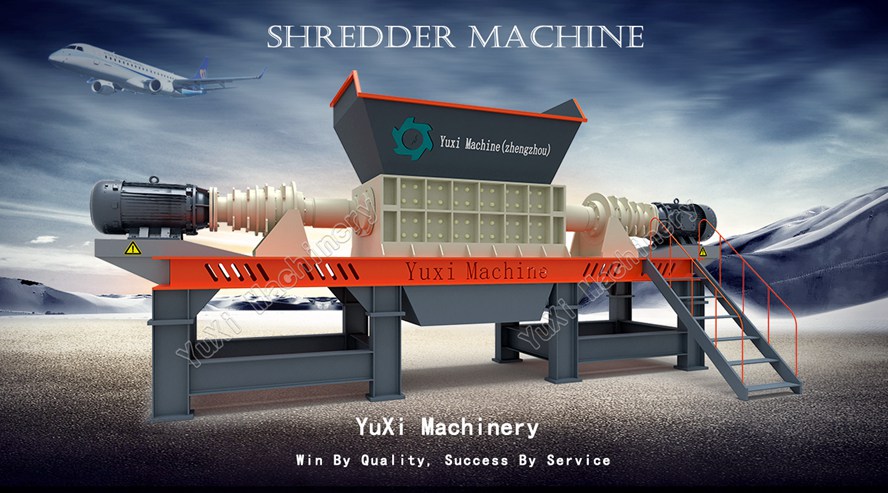

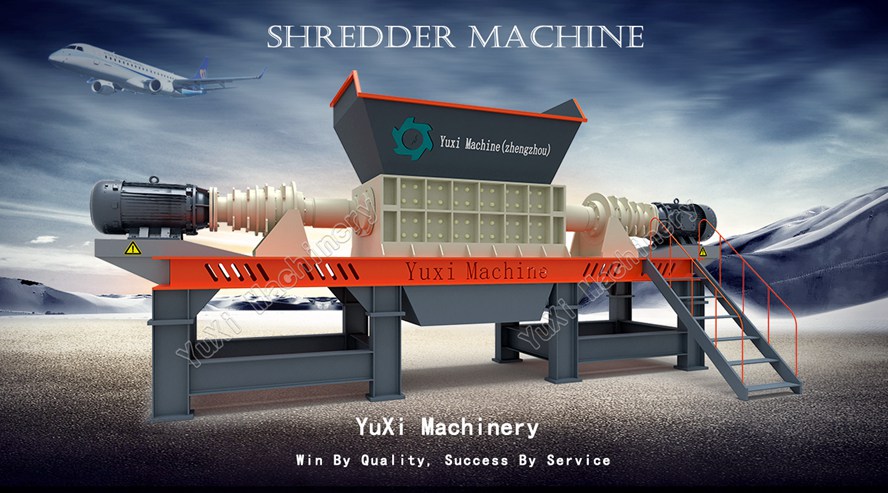

Double-shaft shredder mainly uses the unique double-roller shafts to rotate at a low speed, and performs high-torque extrusion, shearing, tearing and crushing of various materials to achieve the effect of coarse crushing of materials. Double-shaft shredder is composed of conveyor, frame part, two rolling shear rollers, power unit, reducer and other power linkage output structures, etc. Yuxi dual shaft shredder is very good at shredding various metal light and thin materials, woven bags, rubber, waste paper, wood, etc., with good crushing effect.

1. What is the Power Source of the Double Shaft Shredder?

The power structure of the double-shaft shredder is two motors, which transmit the power to the hard-toothed reducer through the V-belt, and the reducer drives two oppositely rotating main shafts of the twin shaft shredder. By reducing the speed of the reducer, the torque of the main shaft is greatly improved, and the two shafts rotate in relative direction. When crushing materials, the materials pass through the rollers from the feeding port, and are crushed by rolling, and the crushed finished products are discharged from the bottom frame. For safety, the transmission part of the two shaft shredder should install the safety cover by customers according to the actual situation.

2. How Does the Twin-shaft Shredder Process Different Materials?

Discharging size control of double-shaft shredder: the blade width, the number of teeth, and the blade shape of the double-shaft shredder can be replaced and adjusted. It can be replaced for different materials, such as materials with higher hardness need a smaller diameter and thicker blade, that is, the reduce the number of rollers and increase the output particle size. On the contrary, when the hardness of the to-be-shredded material is small, the diameter of the blade can be increased to improve the working efficiency; in addition, when the material is too smooth, and it is inconvenient grasped by the blade, the blade with different number of claws can be selected according to the specific material. Since the output size is related to the teeth of the blade, the output particle size can be adjusted by changing the number of blade claws. When increasing the number of claws, the discharging size becomes smaller, while when the number of claws is reduced, the output particle size becomes larger.

3. How to Maintain a Dual-shaft Shredder Machine?

1. During the working of the double-shaft shredder, there should be no abnormal noise. Once there is an abnormal sound, please stop the double-shaft shredder immediately and arrange professional maintenance personnel to overhaul it.

2. The motor should start without load, and after the main shaft speed of the shredder is normal, and all parts are in normal state, the load operation can be started.

3. The screen should be firmly installed, and the screen frame should be firmly fixed.

4. If there is abnormal material jam, bearing or motor heating during working of waste shredder machine, please stop the machine immediately to find out the reason and solve it.

5. After the work of the double-shaft shredder, it is necessary to running without load for 2-3 minutes. It must wait until the residual material is completely discharged before stopping.

6. Strictly abide by the regulations during the production process to ensure safe production, and it is forbidden to increase the speed of the shredder at will.

7. Check the bearing and blade, and replace it with a new one if it is severely worn.

Yuxi double-shaft shredder is reliable in operation, easy in maintenance, low in operating cost, and the discharge particle size can be adjusted. According to the number of cutter rollers, it can be divided into two-shaft shredders and four-shaft shredders. Yuxi twin-shaft shredding equipment is widely used in shredding waste tires, scrap metal, wood, cans, bags, rubber, domestic waste and so on.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment