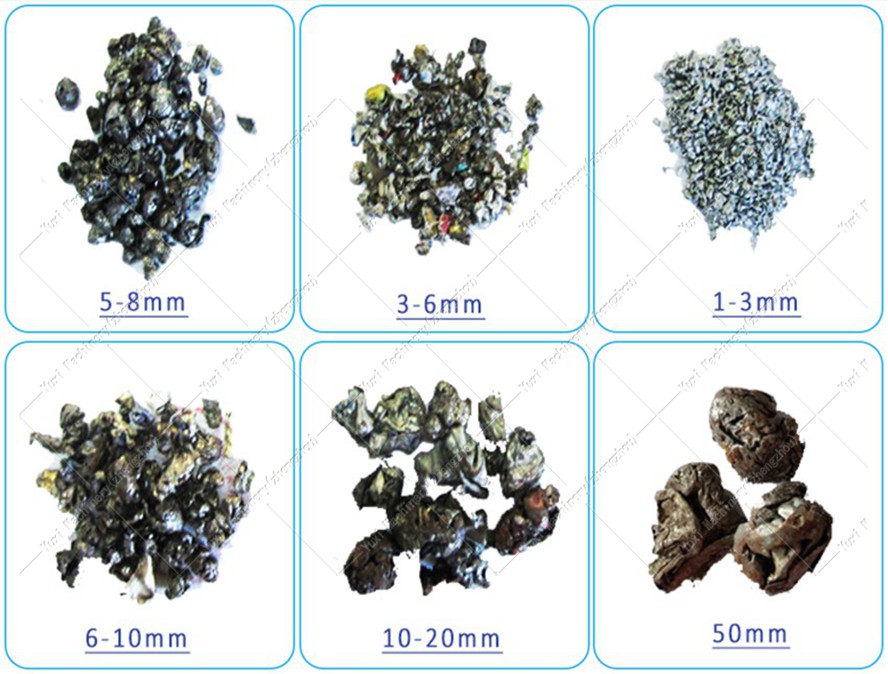

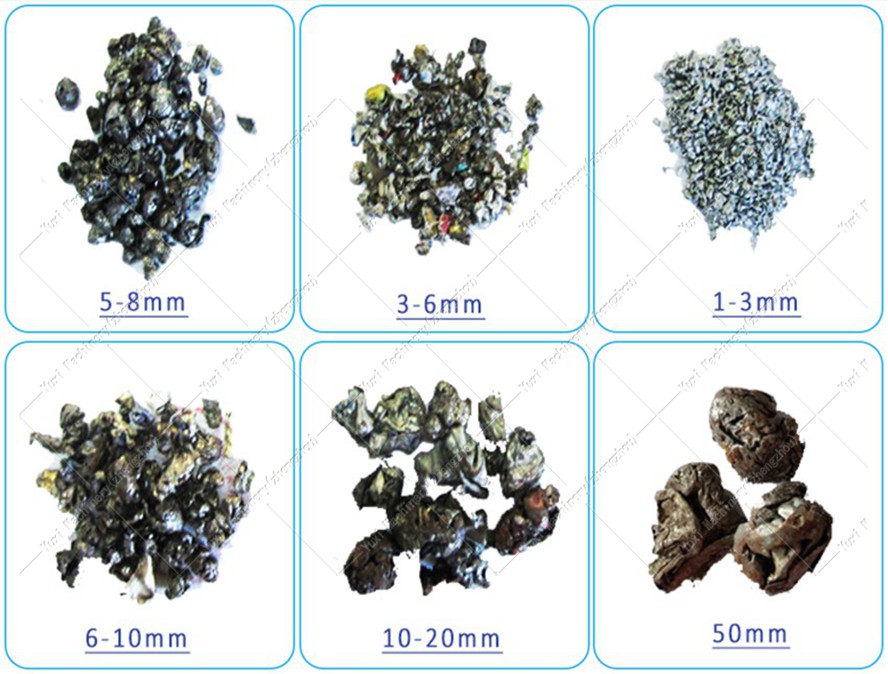

Yuxi scrap steel crushing recycling production line is the most advanced scrap steel processing equipment today. The finished product of scrap steel crushing and recycling production line is clean high-quality steel, with a natural bulk density of 1.2-1.7 t/m3, which is an ideal steelmaking material.

Application: scrap car bodies, tinplate, waste home appliances, bicycles, various tanks and other steel-making scraps.

1. The yield is high, that is, the ratio of produced molten steel to scrap steel is high.

2. The chemical composition of steel in furnace is stable.

3. Since non-ferrous metals and non-metallic substances have been sorted, the sulfur and phosphorus content in molten steel is reduced.

4. When mixed with other scrap steel, the broken steel can fill the gaps and increase the density.

5. When smelting, feeding time is reduced.

6.During smelting, electrode damage is reduced.

7. During smelting, the furnace is heated evenly.

8. The life of the refractory lining in the furnace is prolonged

9. Air pollution and slag are reduced.

10. Reduced power consumption per ton of molten steel.

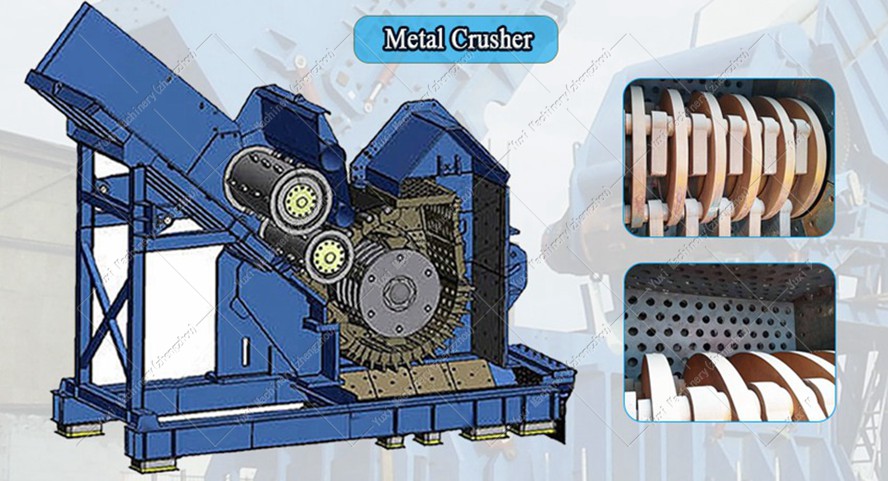

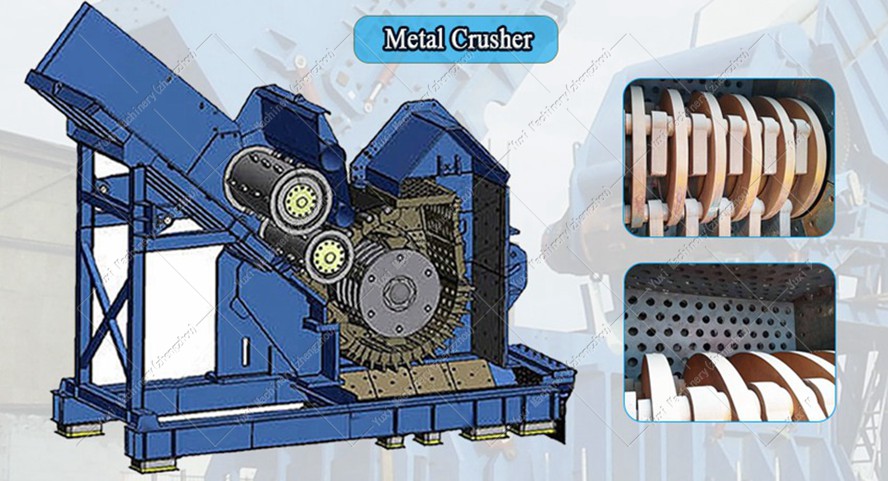

Working principle of scrap steel crushing and sorting production line:

The scrap steel crushing machine uses the principle of hammer striking, driven by the high-speed large torsion high-voltage motor, the hammer head on the rotor of the main machine alternately hits the object to be crushed into the cavity. In the space formed between the liner and the hammer head, the material to be crushed is torn into crushed materials that meet the specifications. Then, under the action of magnetic equipment, high-quality crushed steel with higher purity can be obtained.

What transformer should the scrap steel crushing recycling line be equipped with?

Before investing in the scrap steel crushing production line, market research, site, and sales must be planned in advance. In addition to these three aspects, electric power also needs to be applied for in advance. Different types of scrap steel metal crusher and scrap steel crushing production lines need to be equipped with different transformer models.

1. The total power of 1300 model scrap steel crushing production line is 120kw, and at least a 150 type transformer is required.

2. The total power of complete set of equipment of 1600 model scrap steel crushing and sorting production line is 210kw, and at least type 200 transformers are required, while 250 model and 315 model also can be used.

3. The total power of the 2000 type model scrap steel crushing and recycling production line is 450kw, and it needs to be equipped with a 450 or 500 model transformer.

4. Model 2200, Model 2400, Model 2800 scrap steel crushing and sorting production lines need to be equipped with 10kv high voltage motor.

Feel free to leave us a message for more details and price lists, thank you so much!

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment