What should be paid attention to when choosing crushing equipment for different scrap car parts?

After recycling, scrapped vehicles will be safely dismantled, and it can be ensured that no secondary pollution is caused to the environment during the dismantling process. The dismantled scrapped car shells enter the metal crusher for crushing, and after crushing, plastic, iron, non-ferrous (such as copper, aluminum), sponge and dust can be sorted out, each of which can be recycled and reused. In addition to the dismantled scrapped car shells that can be shredded and recycled, the dismantled scrapped car parts can also be shredded and recycled. Let's take a look at what should be paid attention to when shredding and crushing scrapped car parts.

1. Bumpers and Dashboards

Larger components such as bumpers and dashboards are generally made of reinforced engineering plastics such as ABS, PPO, PP, and PVC. These parts will increase the strength of the material by adding glass fibers, so when crushing and recycling bumpers and dashboards, the requirement on wear resistance of the crusher cutting tool and the inner wall of the crushing cavity is relatively high.

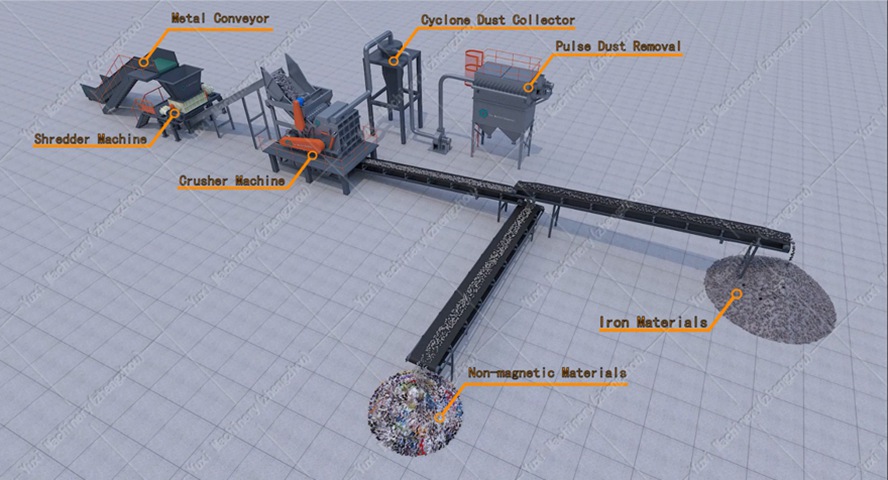

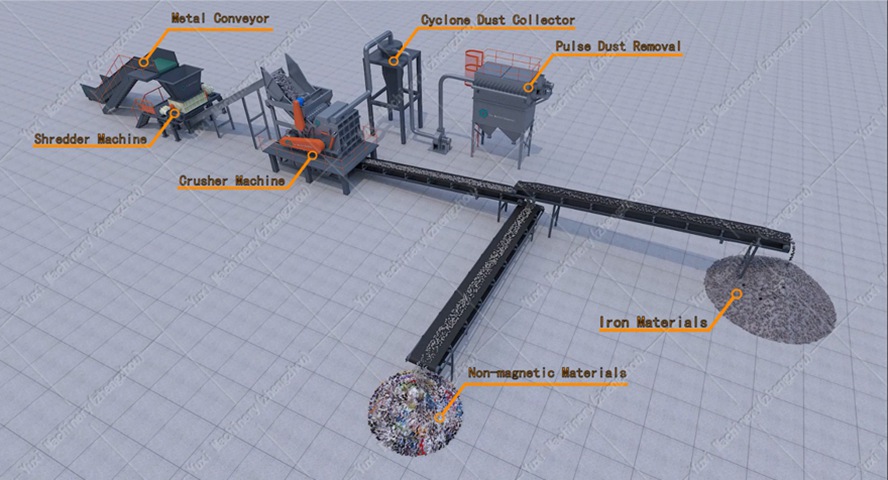

In addition, the size of bumpers and dashboards is relatively large, in order to increase the crushing efficiency, most plants currently use automatic metal crushing line: feeding - crushing - conveying - automatic separation of dust - one-stop bagging. The car shell crushing line only needs 1 manpower to complete the work that can only be completed by 3-5 manpower in the traditional operation mode, and the efficiency is increased by 30-50%.

Technical difficulties: raw materials are with special-shaped structure, large size, containing glass fiber.

2. Steering Wheel, Door Trim Panel, Door and Window Seals, Fenders

Most of these parts are made of PU (foamed), PVC artificial leather, TPV, plastic thermoplastic elastomer, EPDM rubber, etc. The characteristics of these materials are elasticity, strong deformation ability and good hand feeling. In the process of crushing and recycling, these materials are with problems such as soft rubber being difficult to cut, sticking to the knife when heated, caking, and hard-to-cutting.

Technical difficulty: soft elastomer is not easy to cut.

3. Interior, Ceiling

The ceiling is generally made of plastic fiber and plastic wool and linen materials. In a word, this fiber material is made of plastic raw materials, so it can also be crushed by a crusher and then further recycled.

Technical difficulties: plastic fibers are sticky and difficult to recycle.

Solution: The crushing and recycling of such fiber materials is also different from ordinary hard plastics. It has relatively high requirements on the material of the crushing cutting tools: ordinary hard plastics are generally brittle because of their high hardness and are easy to be pulverized under the high speed rotation of the crushing tool shaft, while fibrous materials can only be well broken by shearing and shredding. Therefore, for the crushing of such materials, special attention should be paid to the tool material and cutting angle.

4. Lights, Lampshade

The main importance of car cover parts is transparency and reflective performance, so they are generally made of transparent PC, PMMA, etc. When such materials are crushed and recycled, it is necessary to avoid the contamination of the raw materials by the crusher body, and at the same time, separating the dust generated in the crushing. If powder is infiltrated into the transparent granular material, it is likely to cause yellowing of the product or black spots during molding.

An ordinary crusher can meet the requirements on crushing lights and lampshade, but at the rear end of the crushing, a dust removal device shall be added as much as possible. Dust collector system can remove more than 90% of the dust while bagging, so that when the crushed material is remolded, its performance and molding quality are closer to the raw materials.

5. Brake Pads

The brake pads we are talking about mainly refer to the friction blocks of the brakes, which are divided into two types: metal and non-metal.

Technical difficulties: how to distinguish between metal and non-metal friction pads.

Solution: Some metal friction blocks are made of metal powder by injection molding (MIM). This kind of material has high hardness, strong wear resistance, expensive raw materials, and high manufacturing defect rate. The defective products can be recycled after being broken.

Most non-metal friction blocks are made of asbestos, leather, rubber and other raw materials with various adhesives added. This raw material can also be recycled by crushing. Even if adhesives have been added, they can also be crushed and reused by special wear-resistant crusher machine.

6. Car Tires

The decomposition and recycling of waste tires has now formed an independent industry and is developing rapidly.

The main components of tires are: rubber, steel wire and fiber. Among them, rubber and steel wire have higher recycling value. Rubber particles can be used as materials for laying rubber pavements and floors, and at present, the market is in a state of short supply of rubber particles. The steel wire can be directly recycled and reused.

The tire crushing and recycling equipment is relatively complex. It is a multi-functional production line. The entire system can work independently and fully automatically. The tire is decomposed on the production line, and the steel wire and fiber are separated to obtain clean rubber particles. The working process of the whole automatic tire recycling line is: whole tire----conveying----coarse crushing----conveying---separating steel wire---fine crushing---conveying---separating fiber--- -Bag of rubber pellets.

The shredding of scrapped car is the key to recycling and reuse, and the recycling of scrapped automobiles is an important way to realize the sustainable utilization of resources, which bears huge social responsibility and environmental protection responsibility. As a part of the environmental protection industry, Zhengzhou Yuxi Machinery has designed and developed a series of solid waste shredders in order to help the recycling of scrapped vehicles, including the shearing shredders, coarse shredders, fine shredders, tire shredder, tire cutter, tire rasper, tire steel wire drawing machine, rubber grinding machine, magnetic separator, dust collector, etc. If you are also troubled by the choice of scrapped auto parts crushing equipment, come and leave us a message, thank you!

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment